Aluminum Wheel Prototype by CNC

10.0~30.0 USD

| Min. Order: | 10 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 100Units |

| Place of Origin: | Fujian |

Company Profile

| Location: | Xiamen, Fujian, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Service |

| Main Products: | Plastic Injection Parts, Cnc Machining, Prototype, Moulded Design, Ect. |

Product Detail

| Model No.: | karo-m56 |

|---|---|

| Means of Transport: | negotiation, Ocean |

| Power: | Cnc |

| Raw Material: | Others |

| Machine Type: | Others |

| Extra Services: | Machining |

| Automation: | Automatic |

| Certification: | ISO 9001:2000 |

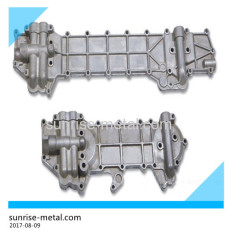

| Material / Metal Processed: | Aluminum |

| Brand Name: | Customized |

| metal prototype: | cnc prototype |

| Production Capacity: | 100Units |

| Packing: | according to customer's requirement |

Product Description

Item No.: | Aluminum Wheel Prototype by CNC |

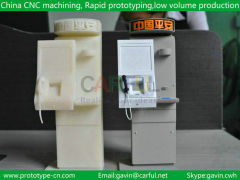

SLA and SLS: | Why Use Stereolithography Stereolithography is very similar to the SLS(Selective LaserSintering) prototyping process.It's best to use SLA,when surface finish andoverall appearance straight from the machine is the most important factor in theprototype. Stereolithography models can also be used as master models, when itcomes time for multiple prototypes to be produced through secondary tooling.TheSLA model is built, the pattern finished and then the silicone rubber is pouredaround the SLA model to produce a tool that will yield 30+ urethanecastings. Why Use Selective Laser Sintering SLS is very similar to the SLA (stereolithography) prototypingprocess.It's best to use SLS,when complex shapes that closely resemble injectionmolded parts are required. |

Surface Finish: | polishing,spray-painting, silk screening, electroplating,anodizing, sand blasting, brush, high gloss, power-coating,e-coat,laser making etc. |

Material Range: | Metal:Stainless Steel,Brass,Aluminium,Steel,Carbon Steel. Plastic:ABS,PP,PC,PU,PVC,POM,PMMA,Nylon. Rubber,Silicone,elastomers etc. |

Prototype Serviced: | 1.Rapid Prototype making(SLA,SLS,FDM). 2.CNC rapid prototype manufacturing. 3.Metal machining. 4.Silicone tooling/urethane casting. 5.Reverse engineering. 6.Industrial Design. 7.Injection Molding. |

Industries Serviced: | Automobile components:Lighting,Instrumentation Clusters,Seatingetc. Computer products:Monitors,Towers,Printers etc. Bathroom Accessories:Faucet,Soap Dispenser,Tumbler Holder, PaperHolder,Head Shower etc. Medical device:Dental Unit,Heart Operation Instrument,Otoscopeetc. Digital Product:TV,DVD Players,Telephones,MP3,MP4,Digital PhotoFrame,Camera,Monitor etc. Homen Appliance:Microwave Oven, Muffle Furnace,InductionCooker,kitchen Cabinet etc. Architectural:Building Model. Toy Model:Plane,Truck,Car Model,Motorcycle Model,Radio Control ToyModel etc. |