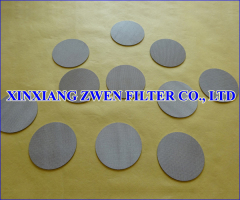

sintered mesh filter disc

1000.0~1200.0 RMB

| Min. Order: | 1 Square Meter |

|---|---|

| Trade Term: | CFR |

| Supply Ability: | 100000000sq.m/month |

| Place of Origin: | Henan |

Company Profile

| Location: | Xinxiang, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Sintered Mesh, Sintered Filter, Sintered Felt, Wheel, Rim |

Product Detail

| Model No.: | 1-300um |

|---|---|

| Structure: | Filtering Machine |

| Function: | Others |

| Material: | Others |

| Brand Name: | meilin |

| Production Capacity: | 100000000sq.m/month |

| Delivery Date: | in two weeks |

Product Description

Filter discSintered wire mesh filter disc for medicine |

Filter disc is the ideal filter originals for filtering, washing and drying machine (three-in-one, for short). Its main material is multi-layer stainless steel sintered mesh. Its filter fineness is 0.5 micron to 200 microns and its diameter is 200-3000mm. The structure of filter disc can be divided into the integral type and separate type. Stainless steel wire mesh is stacked according to the type of structure, and then it sintered after sintering, pressing, rolling and other processes. Five-layer structure is generally divided into the protective layer, filter layer, the separation layer, the reinforcing layer, and the support layer. This kind of filter has both stable filtration precision, and a relatively high strength and stiffness. For the requirement of high compressive strength and filtration requirements of uniform intensity filtering environment, it is a new ideal filter material. Due to its filtering mechanism is membrane filtration, and the mesh is smooth, so the backwash regeneration has excellent performance which can be repeated long-term use, especially suitable for continuous operation and automation of the process .so it is any kind of filter material can't be compared. |

Features |

(1) Strength: As a fourth and fifth layers do support, with high mechanical strength and compressive strength. (2) Easy to clean: As a result of surface of the filter material, having means for cleaning characteristics, especially suitable for backwashing. (3) Easy processing: suitable for cutting, bending, stamping, drawing, welding and other processes. (4) High temperature: 480 ℃ can withstand high temperatures. (5) Corrosion resistance: As a result of SUS316L, 304 materials, the corrosion resistance. (6) Filtration: Filtration range of 1μ-100μ, has a reliable filter performance. (7) Stability: Because there are two layers to do to protect the screen, plus solid melting diffusion sintering process which make filters is not easily to deform. |

Product technical parameters |

Type | Nominal accuracy(um) | Gas Accuracy(L/min·dm2·1000pa) | Bubble Pressure (pa) |

MSW1 | 1 | 180 | 5300-6000 |

MSW2 | 2 | 240 | 4300-5000 |

MSW5 | 5 | 260 | 3000-37000 |

MSW10 | 10 | 310 | 2700-3300 |

MSW15 | 15 | 350 | 2000-2600 |

MSW20 | 20 | 450 | 1800-2300 |

MSW25 | 25 | 620 | 1400-1900 |

MSW30 | 30 | 690 | 1200-1700 |

MSW40 | 40 | 420 | 1000-1500 |

MSW50 | 50 | 850 | 900-1200 |

MSW70 | 70 | 900 | 700-1100 |

MSW100 | 100 | 1080 | 650-1000 |

MSW150 | 150 | 2600 | 500-800 |

MSW200 | 200 | 2800 | 450-600 |

Applications |

(1) Used in extremely high temperatures doing dispersion and cooling. (2) Used for the purpose is to make gas evenly in the powder industry and the application of fluidization plates in steel industry. (3) Used for gas distribution in the fluidized bed. (4) Used to send blast furnace pulverized coal stream is to make it fluidized and conveyed densely in the systems. (5) Used in the pharmaceutical industry, washed and dried. (6) Used in the catalyst support across the grid (7) Used in filtering about polyester, oil, food and beverage, chemical fiber products, also used in water treatment and filtration of gases. |

Note: The difference between sintered filter and ordinary filter Processing technology of sintered filter is different from ordinary filters; The most important point of Sintered felt filter element is that a large number of high-precision welding is used. To ensure roundness and flat, stainless steel sintered filter is sintered after using rolling seam welding process and the method of correction weld, it can make the overall look more beautiful. In this way, it is helpful of the next step to prepare welded filter. The sintered mesh of sintered filter is welded on the end caps at both ends by stainless steel, the welding process can not burn sintered wire mesh, to prevent local burn and resulting not achieve filtration filter, so the welding of the welding process must use argon. All the above must wear special overalls and special welding equipment, welding technology requirements for workers are more stringent, it can prevent the sintered filter from bubbling after welding experiment bubbling air leak in the pressure range. Once that happens, all will be scrapped. |