stainless steel dutch wire mesh

| Min. Order: | 1000 Square Meter |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 200rolls per day |

| Place of Origin: | Hebei |

Company Profile

| Location: | Hengshui, Hebei, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | Devin Wire Mesh Fences |

|---|---|

| Means of Transport: | Ocean |

| Application: | Sieving Diversified Pellet |

| Type: | Woven |

| Material: | Others |

| Brand Name: | Devin Wire Mesh Fences |

| Mesh Size: | 40-100 |

| Production Capacity: | 200rolls per day |

| Packing: | packing with weaven bags |

| Delivery Date: | 20days |

Product Description

Our stainless steel woven wire mesh is generally made of stainless steel wire 302, 304, 304L, 316, 316L, 321 and 430 etc. Among these, type 304 stainless steel wire mesh is the most common one. Stainless steel woven meshhas the features of wear resistance, heat-resisting, acid-resisting, alkali resisting and corrosion resistance. Therefore it's widely used in industry, agriculture, construction, breeding, transport, mining exploitation, transport, entertainment facilities and other public places.

Stainless Steel Woven Wire Mesh Advantages:

* Accurate pore size

* Wide range of aperture sizes

* Can be treated with cleansing agents and air blasted for a longer life.

* Can be resistant to many chemicals

* Wear resistance and durable structure

* Heat-resisting, acid-resisting, alkali resisting and corrosion resistance.

* High temperature resistance and washing resistance

* Good electric conductivity

Stainless Steel Woven Wire Mesh Weaving Type:

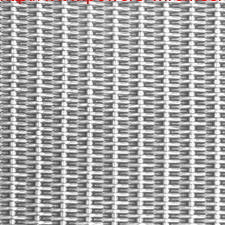

| * Plain Weave The plain weave is the most commonly used and simplest wire cloth weave. Each warp wire (wire running-parallel to length of cloth) passes alternately over and under the wires running traversely through the cloth at 90 degree angles. It has an extremely wide range of applications. Stainless steel plain weave wire mesh offers high filtering efficiency, low pressure loss, constant mesh opening, good dimensional stability, high open surface area and good fireproof property. |

Type | Mesh | Wire Dia mm | Aperture mm | Open Area | Micron |

2# 1.6mm | 2 | 1.6 | 11.1 | 0.7639035 | 11100 |

2# 2.0mm | 2 | 2 | 10.7 | 0.7098394 | 10700 |

3# 1.6mm | 3 | 1.6 | 6.86667 | 0.6577593 | 6866.7 |

4# 0.9mm | 4 | 0.9 | 5.45 | 0.7366235 | 5450 |

4# 1.25mm | 4 | 1.25 | 5.1 | 0.6450493 | 5100 |

4# 1.6mm | 4 | 1.6 | 4.75 | 0.5595511 | 4750 |

5# 1.00mm | 5 | 1 | 4.08 | 0.6450493 | 4080 |

6# 0.9mm | 6 | 0.9 | 3.33333 | 0.6200012 | 3333.3 |

6# 1.25mm | 6 | 1.25 | 2.98333 | 0.4966365 | 2983.3 |

6# 1.6mm | 6 | 1.6 | 2.63333 | 0.3869428 | 2633.3 |

8# 0.56mm | 8 | 0.56 | 2.615 | 0.6783533 | 2615 |

8# 0.63mm | 8 | 0.63 | 2.545 | 0.6425222 | 2545 |

8# 0.71mm | 8 | 0.71 | 2.465 | 0.6027627 | 2465 |

8# 0.9mm | 8 | 0.9 | 2.275 | 0.513423 | 2275 |

10# 0.25mm | 10 | 0.25 | 2.29 | 0.8128371 | 2290 |

10# 0.50mm | 10 | 0.5 | 2.04 | 0.6450493 | 2040 |

10# 0.56mm | 10 | 0.56 | 1.98 | 0.6076632 | 1980 |

10# 0.56mm | 10 | 0.56 | 1.98 | 0.6076632 | 1980 |

10# 0.9mm | 10 | 0.9 | 1.64 | 0.4168888 | 1640 |

12# 0.56mm | 12 | 0.56 | 1.55667 | 0.5408618 | 1556.7 |

12# 0.56mm | 12 | 0.56 | 1.55667 | 0.5408618 | 1556.7 |

12# 0.90mm | 12 | 0.9 | 1.21667 | 0.3303987 | 1216.7 |

14# 0.25mm | 14 | 0.25 | 1.56429 | 0.743397 | 1564.3 |

14# 0.45mm | 14 | 0.45 | 1.36429 | 0.5654566 | 1364.3 |

16# 0.23mm | 16 | 0.23 | 1.3575 | 0.731227 | 1357.5 |

16# 0.23mm | 16 | 0.23 | 1.3575 | 0.731227 | 1357.5 |

16# 0.23mm | 16 | 0.23 | 1.3575 | 0.731227 | 1357.5 |

16# 0.23mm | 16 | 0.23 | 1.3575 | 0.731227 | 1357.5 |

16# 0.35mm | 16 | 0.35 | 1.24 | 0.61 | 1238 |

16# 0.35mm | 16 | 0.35 | 1.2375 | 0.6076632 | 1237.5 |

16# 0.35mm | 16 | 0.35 | 1.2375 | 0.6076632 | 1237.5 |

16# 0.35mm | 16 | 0.35 | 1.2375 | 0.6076632 | 1237.5 |

16# 0.71mm | 16 | 0.71 | 0.8775 | 0.3055391 | 877.5 |

16# 0.45mm | 16 | 0.45 | 1.1375 | 0.513423 | 1137.5 |

18/16# 0.23mm | 17 | 0.23 | 1.26412 | 0.7158226 | 1264.1 |

18/16# 0.28mm | 17 | 0.28 | 1.21412 | 0.6603162 | 1214.1 |

16# 0.45mm | 16 | 0.45 | 1.1375 | 0.513423 | 1137.5 |

18# 0.4mm | 18 | 0.4 | 1.01111 | 0.513423 | 1011.1 |

20# 0.31mm | 20 | 0.31 | 0.96 | 0.5713931 | 960 |

20# 0.35mm | 20 | 0.35 | 0.92 | 0.524769 | 920 |

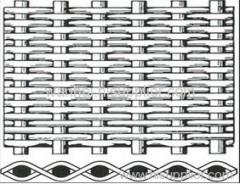

* Dutch Weave

|

Each warp wire and weft wire passes over and under the two nearby wires successively in both the warp and weft directions. This over and under movement is shifted one wire with each pass of the shuttle. The pattern is staggered on successive warp wires, giving the appearance of parallel diagonal lines. This weave allows the use of proportionately heavier wires in a particular mesh count than is possible in plain weave. Crossed twilled wire mesh are basic components in the production of filters, colanders for aliments, chemicals products, shielding, mosquito nets, etc. |

Stainless Steel Woven Wire Mesh Specification:

Mesh Count Warp x Weft | Wire Dia mm | Wire Dia inch | Aperture mm | Aperture inch | Micron Rating |

100 x 100 | 0.1250 | 0.0049 | 0.1295 | 0.0051 | 130 |

120 x 120 | 0.0939 | 0.0037 | 0.1168 | 0.0046 | 117 |

165 x 165 | 0.0482 | 0.0019 | 0.1041 | 0.0041 | 104 |

180x180 | 0.060 | ||||

200 x 200 | 0.0584 | 0.0023 | 0.0685 | 0.0027 | 68 |

250 x 250 | 0.0533 | 0.0021 | 0.0482 | 0.0019 | 48 |

270x270 | 0.040 | ||||

300 x 300 | 0.0355 | 0.0014 | 0.0482 | 0.0019 | 48 |

300 x 300 | 0.0400 | 0.0016 | 0.0431 | 0.0017 | 45 |

325 x 325 | 0.0355 | 0.0014 | 0.0406 | 0.0016 | 41 |

350 x 350 | 0.0304 | 0.0012 | 0.0431 | 0.0017 | 43 |

400 x 400 | 0.0304 | 0.0012 | 0.0330 | 0.0013 | 33 |

450x450 | 0.0304 | 0.0012 | |||

500 x 500 | 0.0254 | 0.0010 | 0.0253 | 0.0010 | 25 |

.jpg)