Double teeth roller crusher

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 100set/month |

| Place of Origin: | Henan |

Company Profile

| Location: | Xinxiang, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Vibrating Screen, Vibrating Feeder, Crusher |

Product Detail

| Model No.: | GF2PGC |

|---|---|

| Means of Transport: | Ocean, Air |

| Motor Type: | AC Motor |

| Power: | 7.4kw |

| Capacity(t/h): | 100-140 |

| Model Numbe: | GF2PGC-120 |

| Certification: | ISO9001:2008 and GE |

| Warranty: | 12 months |

| After-sales Service Provided: | Overseas service center available |

| Material: | carbon steel |

| Supply ability: | Adequate |

| Installation: | Under our engineer's guidance |

| Production Capacity: | 100set/month |

| Packing: | plywood case |

| Delivery Date: | 15-30days |

Product Description

Double Roller Crusher Usage and Application

The double rollers crusher is widely used for secondary and fine crushing in the industry of mining, building materials, chemical industry, metallurgy and so on. It can crush materials in middle hardness such as rocks, ore, coke, lump coal, slag, mineral slag, cement clinker, fireproof materials, and so on.

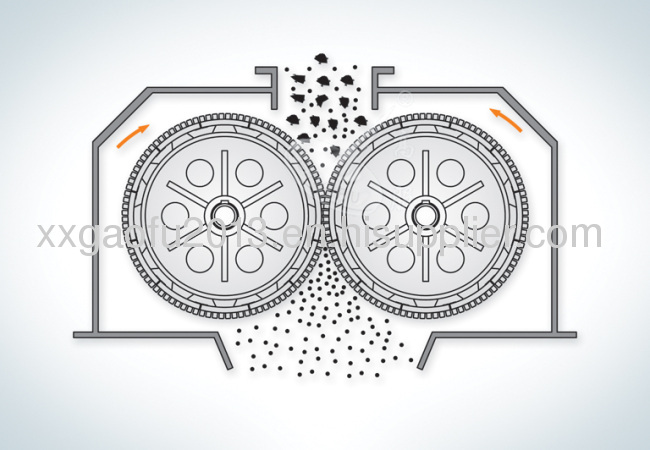

Double Roller Crusher Working Principle

The motor drives the fixed roller and movable roller to work via reducer, V-belts or coupling. Materials are put into the space between the two rollers via the feed entrance. As the two rollers inward turning, the input materials are crushed, pressed, ground, and at last come out from the base of the machine.

Double Roller Crusher Features

1. Compact structure, low noise and efficient;

2. Easy to install and only need simple foundation;

3. Can adjust the pressure and size easily.

4. Self-protection, the parts can not be damaged when hard materials such as the metals goes into the crushing cavity;

5. Low cost maintenance and easy to maintain.

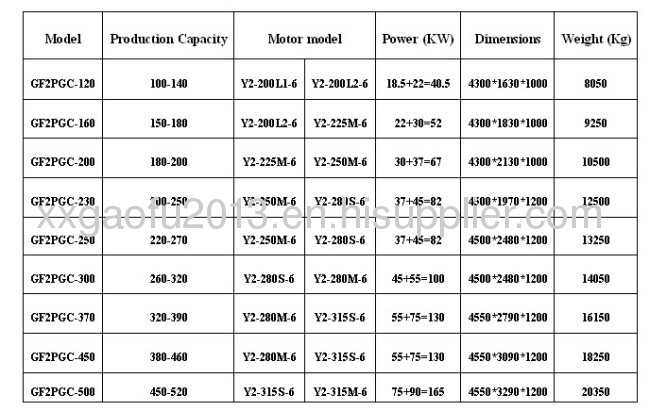

Technical Parameters of double teeth crusher

sketch map:

customer site:

.gif)