6/8/10T capacity waste tyre pyrolysis plant

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | Paypal, L/C, D/P, D/A, T/T, WU, Money Gram |

| Supply Ability: | 20set/ |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Waste Tire/plastic Pyrolysis Oilplant |

Product Detail

| Model No.: | DY-6-8-10T |

|---|---|

| Means of Transport: | Ocean |

| Type: | Excavator |

| Brand Name: | DY |

| Year Built: | 2017 |

| material of Reactor: | Q245R |

| thickness of Reactor: | 16mm |

| rotate speed of Reactor: | 0.4turn/minute |

| Production Capacity: | 20set/ |

| Packing: | wooden package |

| Delivery Date: | 25days |

Product Description

Waste tyre

With the fast development of the society, the amount of the waste tyres is larger and larger. In recent years, the tyre pyrolysis technology has also been developed. The recycled waste tyres are mainly used to make devulcanized rubber and rubber powder. However, producing the devulcanized rubber costs a lot of energy, and causes pollution. So there is a new method, pyrolysis technology. The pyrolysis technology is mature in recent years, and Doing waste tyre pyrolysis plants adopt the latest pyrolysis technology, and the pyrolysis plants can be used in oil sludge treatment, plastic pyrolysis, tyre treatment and so on.

Waste tyre pyrolysis plant

Waste tyre pyrolysis plant

is an environmental protection system which uses the continuous

liquefaction technology and catalytic breakdown reaction to convert

waste tyre into renewable resources, such as pyrolysis oil,carbon

black,steel wire combustible gas and so on.

DY-6T capacity waste tyre pyrolysis plant (D2200mm*L6000mm)

1. This mode of pyrolysis plant can load 6 tons of crushed tires.

2.

After finishing one batch, with auto-feeder, you don't need to wait the

pyrolysis machine cooling down since workers will have to go inside to

feed material. If you don't have one, in that way it will be

time-wasting and dangerous.

3. Built-in spiral plates, these plates will make the waste tires go ahead.

DY-8T capacity waste tyre pyrolysis plant (D2200mm*L6600mm)

1. It can load 8 tons of waste tyres.

2. The reactor adopts Q245R steel plant and its thickness is 16 mm, which can bear 500-750 batches.

3. We can also make reactor by material Q245R, which obviously prolong service life 3-5 times.

4. The reactor has two layers, the outer layer built-in cotton insulation, fire cement and steel.

DY-10T capacity waste tyre pyrolysis plant (D2600mm*L6600mm)

1. Working with Auto-feeder, it is able to contain 12 tons crushed tires or 10 tons whole tires.

2. For plastic, it can contain even 12 tons.

3. The diameter of feeding port is 1200mm or 1400mm.

After

2 hours feeding time, it's time to heat the reactor by

coal/wood/natural gas/crude oil. Generally speaking, when the

temperature ups to 155 Celsius degrees around, the oil gas will

generate.

Waste tyre working time you may need:

let's take 10 tons waste tires that processed by DOING waste tyre pyrolysis plant as an example:

| Model | Feeding | Processing | Cooling | Discharge | Total |

| 2200*6000 | 1.5hr | 7-8hr | 1.5hr | 1.5hr | 12hr |

| 2200*6600 | 1.5hr | 8hr | 1.5-2hr | 1.5hr | 14hr |

| 2600*6600 | 2 hr | 10 hr | 2-3 hr | 2-3 hr | 16-18 hr |

6/8/10T capacity waste tyre pyrolysis planttechnical data

| Technical parameter of 6/8/10T capacity waste tyre pyrolysis plant | ||||

| No. | Items | Contents | ||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | Waste tyre | Waste tyre | Waste tyre |

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

| Prepared by customer about 6/8/10T capacity waste tyre pyrolysis plant | |||

| No. | Item | Consumption | |

| 1 | Coal(for choice) | 500kg/day | |

| 2 | Wood(for choice) | 800kg/day | |

| 3 | Natural gas(for choice) | 100-150kg/day | |

| 4 | Oil(for choice) | 300-350kg/day | |

| 5 | Electricity | 244kwh/day | |

| 6 | Water(recycled) | 60㎥ /month | |

| 7 | Total power | 19kw | |

| 8 | Land area | 35m*15m | |

6/8/10T capacity waste tyre pyrolysis plant final product application

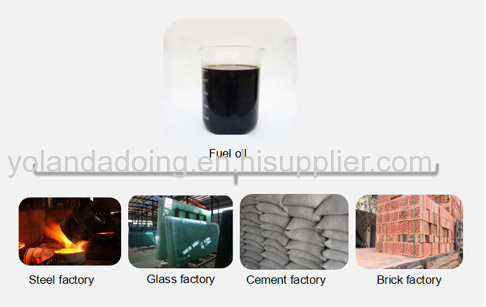

Fuel oil (40% to 45%)

Fuel oil application

The

main oil product produced by our recycling application is the fuel oil

that is wide used for industrial and commercial purposes. The oil has

40% to 45% of the amount of recycled scrap tyres, which will be carried

with licensed tanker trucks.

Carbon Black (30% to 35%)

Carbon black application

Carbon

Black is the main product recycled by Pyrolysis technology. The amount

of recycled carbon black is 30% to 35% (depending on the type of tyres)

of the total amount of scrap tyres recycled in the system. Carbon black

is used as raw material or main ingredient in many industries and the

chemical structure of carbon black strengthens, lengthens the endurance,

and improves the coloring features of the materials.

Carbon

black produced by Pyrolysis process (CBp) is more economical compared to

carbon black produced primarily from petroleum and is more

price-efficient to be used as an ingredient in the industries listed;

* Electric cable jacketing

* Conveyor band

* Carrier Bands

* Hose and doormat

* Black nylon bag

* Rubber additive

* Automotive spare parts

* Heat isolation

* Black colorant in rubber materials

* Plastic pipes

* Industrial rubber products

* Fire fighting

Steel wire (10% to 15%)

Tyres

contain steel wires and the amount range of 10% to 15% of the total

tyre wastage. All of the steel present in the tyre can be detached after

pyrolysis recycling process in completed. Valuable steel wires are

pressed and sold to steel and scrap dealers.

Gas (10% to 12%)

Non-Condensable gases arise during the pyrolysis process.

Some advantages such as…..

* It has higher calorific value as compared to Natural Gas.

* It can be replaced where Natural Gas and Propane are stored.

* The high energy gas may be utilized as a source of energy for the Pyrolysis process.

*

The amount of gas generated in the system is 12% to 15% of the total

amount of recycled tyres and considering the 10 ton scrap tyre/day

recycling capacity, the facility generates 1200-1500 m3/day gas, which

has an enormous energy potential when evaluated.

Contact: Ms Bonnie

Skype: bonniezhao2

www(dot)wastetireoil(dot)com

www(dot)doinggroup(dot)com