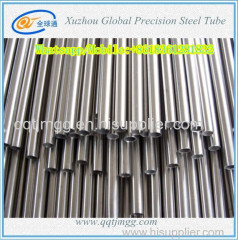

Seamless Precision steel tubes

| Place of Origin: | Hebei |

|---|

Company Profile

| Location: | Cangzhou, Hebei, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Service |

| Main Products: | Butt Welded Pipe Fittings 90D Elbow, 45D Elbow, 180D Elbow, Cap, Straight Tee |

Product Description

The seamless precision steel tubescan be used for a wide range of precision mechanical spare for car andcylinder accord to standard DIN2391/ EN10305-1/ GB/T3639-2009.

DIN 2391-81 Part 2 Seamless Precision steel tubes(DIN2391-81)

Seamless Precision Steel Tubes according to EN 10305-1

- Standard: DIN2391 part 2 , DIN EN10305-1, DIN17175 etc;

- Material: ST35,ST45,ST52.

- Manufacturing method: cold-rolled / cold-drawn

- Delivery condition: BK,BKS,SR,GBK,NBK.

- Certificate

- Factory Certification: 2.2 according to EN

- Acceptance Test Certificate:3.1 according to EN 10204

- Packing:

- in bundles tied with steel strips. External packing by wooden cases if the wall thickness/OD ratio is low.

- Oil-coating is generally necessary especially for export.

- Application:

Usedin hydraulic & pneumatic cylinder ,automobile and other mechanicaldevice .Feature: high precision and high brightness, the inner and outersurface of the tubes have high cleanness without oxid, mechanicalproperties of the final tubes also come out excellent, promising noleakage under high pressure, no deformation after cold-bent and nocracks when flaring and flattening, ensuring the efficient operation inall service.

DIN 2391-81 Part 2 Seamless Precision steel tubes(DIN2391-81)

Standard DIN 2391defines the technical delivery conditions for seamless precision steeltubes according to DIN 2391 Part 1 which are made from the steel gradeslisted in section 5.

Tubes according to thisStandard are mainly used where accuracy to dimension and, possibly,small wall thicknesses and good surface condition are required.

Tubes according to thisStandard are mainly used where accuracy to dimension and, possibly,small wall thicknesses and good surface condition are required.

Chemical composition(%)

| Code number | Material number | Mfg. Process | C max | Si max | Mn max | P max | S max |

| St35 | 1.0308 | S | 0.17 | 0.35 | 0.4 | 0.05 | 0.05 |

| St45 | 1.0408 | S | 0.21 | 0.35 | 0.4 | 0.05 | 0.05 |

| St52 | 1.0508 | S | 0.22 | 0.55 | 1.6 | 0.05 | 0.05 |

Mechanical and technological properties

| Code number | Material number | Cold-finished hard(BK) | Cold-finished/soft (BKW) 3) | ||

| Rm(Mpa) | A(%) | Rm(Mpa) | A(%) | ||

| St 35/E235 | 1.0308 | 480 | 6 | 420 | 10 |

| St 45 | 1.0408 | 580 | 5 | 520 | 8 |

| St 52/E355 | 1.0508 | 640 | 4 | 580 | 7 |

| Code number | Cold finished (soft)(BKW) | Annealed (GBK) | Normalized (NBK) | |||||

| Rm(Mpa) | ReH (Mpa) | A(%) | Rm(Mpa) | A(%) | Rm (Mpa) | ReH (Mpa) | A(%) | |

| St 35/E235 | 420 | 315 | 14 | 315 | 25 | 340-470 | 235 | 25 |

| St 45 | 520 | 375 | 12 | 390 | 21 | 440-570 | 255 | 21 |

| St 52/E355 | 580 | 450 | 10 | 490 | 22 | 490-630 | 355 | 22 |

Note:

- The yield point for theannealed (GBK)condition on delivery is at least 50% of the (ultimate)tensile strength. Depending upon the degree of deformation in thedrawing operation, the yield point of tubes delivered in thecold-finished/hard (BK)and cold-finished/soft(BKW) conditions, may beincreased to a level close to the tensile strength.

- In calculating the yieldpoint, the following values are recommended : cold-finished/hardcondition on delivery ≥ 80% of the tensile strength, cold-finished/softcondition on delivery ≥ 70% of the tensile strength.

Quality grade

The tubes are supplied in the following quality grades :

A) precision steel tubesintended primarily for mechanical stressing, without any particularquality requirement and without acceptance test certificate.

B)precision steel tubes intended primarily for mechanical stressing, withspecial quirement and exclusively with acceptance test certificate.

C)precision steel tubes with special requirement according to section 12.Theses requirements and corresponding tests must be agreed, with thecustomer having to specify his requirements at the time of enquiry andon ordering.

B)precision steel tubes intended primarily for mechanical stressing, withspecial quirement and exclusively with acceptance test certificate.

C)precision steel tubes with special requirement according to section 12.Theses requirements and corresponding tests must be agreed, with thecustomer having to specify his requirements at the time of enquiry andon ordering.

Condition on delivery:

| Term | Symbol | Explanation |

| Cold-finished/hard (cold-finished as-drawn) | BK | No heat treatment after the last cold-forming process. The tubes therefore have only low deformability. |

| Cold-finished/soft (lightly cold-worked) | BKW | After the lastheat treatment there is a light finishing pass (cold drawing) Withproper subsequent processing, the tube can be cold-formed (e.g. bent,expanded) within certain limits. |

| Annealed | GBK | After the final cold-forming process the tubes are annealed in a controlled atmosphere or under vacuum. |

| Normalized | NBK | The tubes are annealed above the upper transformation point in a controlled atmosphere or under vacuum. |