2013 new design grain screw conveyor

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Trade Term: | FOB,CFR,CIF |

| Payment Terms: | L/C, Escrow, T/T, WU |

| Supply Ability: | 100sets /month |

| Place of Origin: | Henan |

Company Profile

| Location: | Xinxiang, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Vibration Equipment |

Product Detail

| Model No.: | GX200X10M |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | DY |

| Condition: | New |

| Certification: | ISO9001:2008 |

| Conveyor Width: | As you required |

| Structure Material: | Carbon steel or as the customer |

| Performance: | Perfect |

| Model Number: | B400,different |

| Type: | Screw conveyor |

| Production Capacity: | 100sets /month |

| Packing: | Wooden packing. the packing size should be according to the actual size |

| Delivery Date: | 15 days after receipt of payment |

Product Description

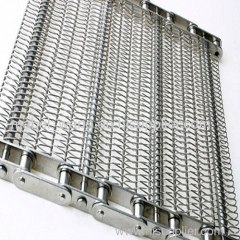

Grain conveyor

About company

We are a professional factory to produce vibration equipment,crusher,conveyer and grain conveyor

.Our company is a new-type shareholding system company which combines several decades of

manufacturing experience and modern technology together.At present we have established a

long-term cooperative partnership with the United States, Germany, Turkey, Indonesia, Tunisia and

other countries.We are expecting to establish a long-term and win-win business relationship with the

customers.

Product Description

| working principle | a. There are two same vibration motor to be fixed on vertical screw slot. And they corotate by a contrary direction. The corotation will emerge a Centrifugal force to make a reciprocating motion by the throwing direction. b. Then the the vertical screw slot will begin to continuous vibrating. Then the material in the vertical screw slot will be threw to move up. In the process of Moving up, the material also can be heat emission and cooled at the same time. |

| Advantages | 1.Working temperature is -20~50°C, with material temperature below 200°C; |

2.Inlet trough with progressive solid-flight screw for uniform storage bin discharge ; | |

3.Adopt high-quality reducer with heavy-duty design, large torque and low noise ; | |

4.Adopt once-forming spiral double pitch paddles, which will never block the material ; | |

5.Inlet trough with progressive solid-flight screw for uniform storage bin discharge ; | |

| 6.Hopper is adjustable and vibrational which make material to flowing easily. | |

| Application | A shaft welded with screw is installed in a trough type casing. Granular or pulverulent products are fed into the machine and transferred straight forward . |

Technical parameter

Model | Transmission length | Capacity (T) | Motor power(KW) | Weight(T) | ||

Coal | Cement

| Raw material | ||||

GX200X10M | 3-70M | 8.5 | 7.9 | 7.3 | 2.2 | 0.7 |

GX250X10M | 3-70M | 16.5 | 15.6 | 13.8 | 3 | 0.95 |

GX300X10M | 3-70M | 20 | 21 | 18.7 | 3 | 1.4 |

GX400X10M | 3-70M | 54 | 51 | 45 | 5.5 | 2.1 |

GX500X10M | 3-70M | 79 | 84.4 | 74 | 7.5 | 3.2 |

We are looking forward to your inquiry!

If you are interested in grain conveyor ,pls email or call us.

welcome to visit our factory and look forward to your cooperation.