BALL BEARING 16 SERIES 1616

0.8 USD

| Min. Order: | 5000 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T |

| Supply Ability: | 0.3 MILLION PCS PER MONTH |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Service |

Product Detail

| Model No.: | 1616 1616-Z 1616-2RS |

|---|---|

| Brand Name: | JUF |

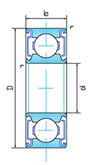

| SIZE: | 12.7*28.575*9.525 |

| MATERIAL: | GCR15 |

| GREASE: | JUF3# |

| PRECISION GRADE: | P0/P6/P5 |

| FITNESS: | C0/C3 |

| OEM SERVICE: | AVALABLE |

| PACKING: | TUBE |

| MARKING: | JUF or NEUTRAL or BLANK |

| Production Capacity: | 0.3 MILLION PCS PER MONTH |

| Packing: | TUBE |

| Delivery Date: | 20 DAYS |

Product Description

Deep Groove Ball Bearing Inch Series 1616

| Product Number | Bearing Type | Bore Dia (d) | Outer Dia (D) | Width (B) | Dynamic Load Rating (Cr) (Newtons) | Static Load Rating (Cor) (Newtons) |

| 1616 | Open | 0.5 | 1.125 | 0.375 | 1150 | 450 |

| 1616-2rs | Sealed | 1.125 | 0.375 | 1150 | 450 | |

| 1616ZZ | Shielded | 1.125 | 0.375 | 1150 | 450 |

Lubrication | ||||

| There is no known universal grease for all bearing applications; it is therefore required to have a complete understanding of the operational environment. Because conditions of service are often difficult to properly analyze, we recommend you consult our engineering department for recommendations. There are many fine selections available, here are only a few: | ||||

Lubrication | Temperature | Base Oil | Thickener | MIL-Spec |

| Range (F) | ||||

| Alvania #2 | -30 to +230 | Petroleum | Lithium Hydroxy | MIL-G-18709A |

| Beacon 325 | -60 to +250 | Synthetic | Lithium Hydroxy | MIL-G-3278A |

| Chevron SRI #2 | -20 to +350 | Petroleum | Polyurea | MIL-G-3545C |

| Kyudo Yushi SRL | -40 to +300 | Synthetic | Lithium Hydroxy | |

| Mobil Grease 28 | -80 to +350 | Synthetic | Synthetic | MIL-G-8132 |

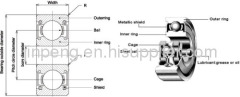

| Retainers (Cages) | ||||

| Cages are used to perform an important function, the separation of the rolling elements within the bearing races. It is important for a smooth and efficient operation that the rolling element be guided in and out of the load zone. Retainers come in several configurations and material types that include: | ||||

| Pressed Steel Finger | ||||

| Pressed Steel Riveted | ||||

| Molded Nylon | ||||

| Shields | ||||

| Especially configured low carbon non-removable steel plates (Z) are staked into the outer ring of the bearing to provide protection against coarse dirt or chips from contaminating the bearing. Shields are especially useful in high temperature applications and where low torque is required. Stainless Steel is available upon request. | ||||

| Seals | ||||

| Radial bearings fitted with rubber seals (RS) in the outer ring, provide a wiping action to provide an effective barrier against contamination. Seals contain a carbon steel plate to assist in keeping the seal from being pushed inward by external forces. Seals with light wiping action provide lower torque and are often called non-contact seals. Materials selected for use often depend on the operating temperature of the application. Materials include: | ||||

| Buna N | ||||

| Polyacrylic | ||||

| Fluroelastomer | ||||

| Silicon | ||||

| Electric Motor Quality | ||||

| For a quiet and smooth operation, VNC supplies electronically tested Electric Motor Quality (EMQ). Bearings are 100% tested for noise and vibration according to ANSI/ABMA Standard 13-1987. | ||||

| Tolerances | ||||

| JUF Bearings manufactures bearings to ABEC 1 dimensional tolerances. ABEC 3, 5 are also available. | ||||

| Internal Radial Clearances | ||||

| Our standard product line is normally produced with "C0" radial clearance. Other radial clearances are available. | ||||