GCR15 DGBB 6303 6303-ZZ 6303-2RS

0.5 USD

| Min. Order: | 5000 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T |

| Supply Ability: | 0.5 MILLION PCS PER MONTH |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Service |

Product Detail

| Model No.: | 6303 6303-ZZ 6303-2RS |

|---|---|

| Brand Name: | JUF |

| SIZE: | 17*47*14 |

| MATERIAL: | GCR15 SAE52100 |

| GREASE: | JUF3# |

| PRECISION GRADE: | P0/P6/P5 |

| FITNESS: | C0/C3 |

| OEM SERVICE: | AVALABLE |

| PACKING: | TUBE |

| MARKING: | JUF or NEUTRAL or BLANK |

| Production Capacity: | 0.5 MILLION PCS PER MONTH |

| Packing: | TUBE |

| Delivery Date: | 20 DAYS |

Product Description

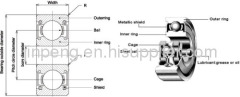

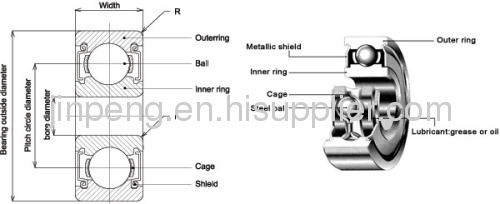

Deep Groove Ball Bearings are used to provide smooth, low friction motion in rotary applications. Deep Groove Ball Bearing are able to accommodate low to heavy radial loads and low to moderate thrust loads in either direction. They are available with metal shields (ZZ) or rubber seals (2RS). Several tolerance grades (Abec 1-9), internal clearance (C2 to C4) and cage designs are available to best suit the running precision and speed of the application.

Deep groove ball bearings types:

1, single row deep groove ball bearings

2, single row deep groove ball bearings with dust cover

3, with a dust cover, a ring of single row deep groove ball bearings

4, the outer ring on the stopper groove and snap ring of single row deep groove ball bearings

5, deep groove ball bearings ball gap

6, double row deep groove ball bearings

2, single row deep groove ball bearings with dust cover

3, with a dust cover, a ring of single row deep groove ball bearings

4, the outer ring on the stopper groove and snap ring of single row deep groove ball bearings

5, deep groove ball bearings ball gap

6, double row deep groove ball bearings

1.Deep groove ball bearing 6011

2.Material:

RINGS & BALLS vacuum degassed, high carbon chromium bearing steel GCr15 is the standard material for precision bearing rings and balls. The material has uniform specification as AISL 52100(America)DIN100 Cr6(German),JISSUJ2(Japan)

RINGS & BALLS vacuum degassed, high carbon chromium bearing steel GCr15 is the standard material for precision bearing rings and balls. The material has uniform specification as AISL 52100(America)DIN100 Cr6(German),JISSUJ2(Japan)

Chemical Composition(%) | ||||||

STEEL NO | C | Si | Mn | P | S | Cr |

GCr15 | 0.95-1.05 | 0.15-0.35 | 0.25-0.45 | 0.025 | 0.025 | 1.40-1.65 |

RETAINERS-LB standard bearing retainers are made from cold rolled carbon steel

3.precision grade: P0/P6/P5/P44.OEM service

6.Quality Guarantee : The items can be replaced or refunded beause of quality problem within one year from the date the buyer get the goods .

Inspection and Test

In the whole course from purchasing of raw materials to every process of production, "LB"Brand besrings are all strictly and carefully inspected to guarantee quality.Besides the basic and normally used testing instruments,the company also adopts the following testing and inspecting instruments to control the production processes and finished products.

(1): HV-4B Pc high-speed automatic carbon and sulfur analyser Chemical composition of raw material

(2): HC-II High-speed digital display automatic analyzer

(3): 4X1 Metallurgical microscope Analysis of material and metallurgical structure

(4): Y9025 Roundness measuring equipment Roundness of groove and outer diameter

(5): R902 Groove curvature inspecting instrument Groove curvature and groove shape

(6): SRM-1 Surface roughness inspecting instrument Roughness of groove and surface

(7): S0910 Bearing vibration inspecting instrument (Accelerationg)vibration and abnormal sound

(8): BVT-1 Bearing vibration inspecting instrument (speed) vibration and abnormal sound

(1): HV-4B Pc high-speed automatic carbon and sulfur analyser Chemical composition of raw material

(2): HC-II High-speed digital display automatic analyzer

(3): 4X1 Metallurgical microscope Analysis of material and metallurgical structure

(4): Y9025 Roundness measuring equipment Roundness of groove and outer diameter

(5): R902 Groove curvature inspecting instrument Groove curvature and groove shape

(6): SRM-1 Surface roughness inspecting instrument Roughness of groove and surface

(7): S0910 Bearing vibration inspecting instrument (Accelerationg)vibration and abnormal sound

(8): BVT-1 Bearing vibration inspecting instrument (speed) vibration and abnormal sound

Installation

The bearing installation has close relationships with the accuracy, life and performance. Therefore the design and assembly departments should fully research into the bearing installation.

It is better to implement installation according to the operation standard. The items of the operation standard are usually as follows:

(1) Clean bearing and its related parts

(2) Check the size and finishing conditions of the related parts

(3) Installation

(4) Examine bearings after installation

(5) Feed the lubricant

It is better to implement installation according to the operation standard. The items of the operation standard are usually as follows:

(1) Clean bearing and its related parts

(2) Check the size and finishing conditions of the related parts

(3) Installation

(4) Examine bearings after installation

(5) Feed the lubricant