THIN SECTION BEARING 6800 SERIES

0.25~2.5 USD

| Min. Order: | 10000 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 1 MILLION PCS PER MONTH |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Service |

Product Detail

| Model No.: | 6800 61801 61802 61803 61804 6805 |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | JUF |

| SIZE: | ID=8-60MM |

| MATERIAL: | GCR15 |

| PRECISION GRADE: | ABEC1/ABEC3/ABEC5 |

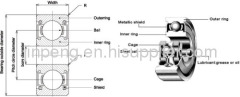

| SEAL TYPE: | OPEN ZZ 2RS |

| SERVICE: | OEM ACCEPTED |

| PACKING: | INDUSTRIAL & INDIVIDUAL PACKING |

| FITNESS: | C0 C2 C3 |

| Production Capacity: | 1 MILLION PCS PER MONTH |

| Packing: | INDUSTRIAL &INDIVIDUAL PACKING |

| Delivery Date: | 35 DAYS |

Product Description

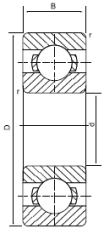

| Bearing Specification 68 Series |

Basic Bearing No. | Bore d mm inch | Outer Diameter D mm inch | Width W Mm inch | Radius r mm inch | Basic Load Rating KN | Maximum Run out Speed | Weight Kg/pc | ||

Dynamic C | Static C0 | Grease r/min | Oil r/min | ||||||

685 686 687 688 689 | 5 1969 6 .2362 7 .2756 8 .315 9 .3543 | 11 .4331 13 .5118 14 .5512 16 .6299 17 .6693 | 3 .1181 3.5 .1378 3.5 .1378 4 .1575 4 .1575 | 0.15 .006 0.15 .006 0.15 .006 0.2 .008 0.2 .008 | 0.715 1.08 1.17 1.26 1.72 | 0.282 0.44 0.51 0.585 0.82 | 35000 33000 31000 29000 28000 | 45000 42000 40000 38000 36000 | 0.0011 0.0019 0.0021 0.0031 0.0032 |

6800 6800W7 6801 6802 6803 6804 6805 6806 6807 6808 6809 6810 | 10 .3937 10 .3937 12 .4724 15 .5906 17 .6693 20 .7874 25 .9843 30 1.1811 35 1.3780 40 1.5748 45 1.7717 50 1.9685 | 19 .7480 19 .7480 21 .8268 24 .9449 26 1.0236 32 1.2598 37 1.4567 42 1.6535 47 1.8504 52 2.0472 58 2.2835 65 2.5591 | 5 .1969 7 .2756 5 .1969 5 .1969 5 .1969 7 .2756 7 .2756 7 .2756 7 .2756 7 .2756 7 .2756 7 .2756 | 0.3 .012 0.3 .012 0.3 .012 0.3 .012 0.3 .012 0.3 .012 0.3 .012 0.3 .012 0.3 .012 0.3 .012 0.3 .012 0.3 .012 | 1.83 1.83 1.92 2.08 2.81 4.00 4.30 4.70 4.90 5.10 6.40 6.60 | 0.925 0.925 1.04 1.26 1.72 2.47 2.95 3.65 4.05 4.40 5.65 6.10 | 26000 26000 22000 20000 19000 17000 15000 13000 11000 9000 7000 5000 | 34000 34000 30000 28000 26000 22000 19000 17000 15000 13000 11000 9000 | 0.005 0.006 0.006 0.007 0.008 0.019 0.022 0.026 0.029 0.033 0.040 0.052 |

Installation

The bearing installation has close relationships with the accuracy, life and performance. Therefore the design and assembly departments should fully research into the bearing installation.It is better to implement installation according to the operation standard. The items of the operation standard are usually as follows:

(1) Clean bearing and its related parts

(2) Check the size and finishing conditions of the related parts

(3) Installation

(4) Examine bearings after installation

(5) Feed the lubricant

The bearing packing should be opened shortly before installation. There is no need for cleaning to ordinary lubricating grease lubrication, direct-filling of lubricating grease or lubricating oil. Whereas it should use the clean oil to rinse the instrument purpose bearing or high speed purpose bearing etc. and get rid of the anti-rusting agent on the bearing. The bearing easily gets rusty without rust inhibitor. Therefore special care should be taken to such kind of the bearing.

What is more, the bearing which has been sealed with lubricating grease can be put into direct use with no cleaning at all.

The installation methods of the bearing vary according to the difference in the bearing structure, matching, condition. As it is mostly of axle rotation, the inner ring needs interference fit. The cylindrical bore bearing is commonly pressed in by pressing machine or most probably, it adopts the heat installation method. The taper hole can be directly

installed in the taper axle or by sleeving.

When it has been mounted to outer casing, usually it has excess clearance fit, the outer ring has shrink range, it will be pressed in