Bunching and stranding dies

| Min. Order: | 5 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 5000Pcs/Month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Hangzhou, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Polished Shaft Rolling Ring Drive Linear Bushings, RG Linear Drive Ball Screw Linear Actuator, Mini Portable Welding Machines, Winding Assemblies Automotive Linear Actuator, Rolling Ring Drive Linear Drive Motor |

Product Detail

| Model No.: | LS-D004 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Product: | Others |

| Product Material: | Metal |

| Shaping Mode: | Die Casting |

| Brand Name: | LS |

| Material: | Polycrystalline diamond |

| Application: | Wire drawing |

| Size: | 0.127mm to 76.2 mm |

| Production Capacity: | 5000Pcs/Month |

| Packing: | Carton Box |

| Delivery Date: | It depends on QTY |

Product Description

Bunching and stranding dies

Features

Dies used to guide and/or form wires entering, moving through, and/or exiting bunching and stranding machines.

In the case of double and single twist bunchers, with the take-up reel on the inside of the machine, the dies are located at the entrance of the machine to gather the incoming wires.

Sometimes, the dies are located before the take-up reel inside the machine to shape the wire that goes onto the reel.

In the case of tubular and planetary stranders, stranding dies are used inside the machine to guide the wires and to gather and form the wire prior to going on the reel outside of the machine.

Blank (Nib) material

Carbide, PCD, natural diamond, synthetic single crystal, ceramic.

Casing

Stainless and cold rolled steel.

Geometry

Size ranges from 0.380 mm to over 35 mm (.015" to over 1.38") depending on the cable size being manufactured.

Tolerance is generally plus or minus 1% of the hole diameter.

Angle range is generally 18 to 24 degrees plus or minus 2 degrees.

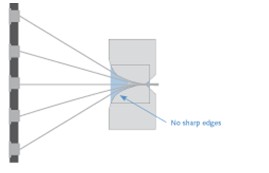

Bunching and stranding dies must have a well-blended profile with no sharp edges.

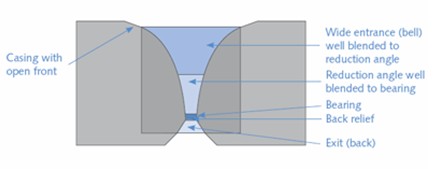

Parts of the die

Design considerations

Entrance (Bell)

The entrance of a bunching or stranding die must be wide enough to accept the incoming wires from the lay-plate without scraping.

Reduction angle

The standard angle is 20 to 24 degrees. The wider angle allows for a good blend from the entrance to the reduction angle.

Bearing length

The bearing length for random bunched wires is not critical. The purpose of the die is to gather the wires from the lay plate and direct them into the machine. The bearing length for concentric and unilay constructions is usually longer to help hold the wires in position as they enter the machine.

Certification

Shipping Way