Transparent PET Film for packaging/wrapping/printing

| Min. Order: | 500 Kilogram |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 1000Ton/Month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Hangzhou, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Polished Shaft Rolling Ring Drive Linear Bushings, RG Linear Drive Ball Screw Linear Actuator, Mini Portable Welding Machines, Winding Assemblies Automotive Linear Actuator, Rolling Ring Drive Linear Drive Motor |

Product Detail

| Model No.: | LS-PET001 |

|---|---|

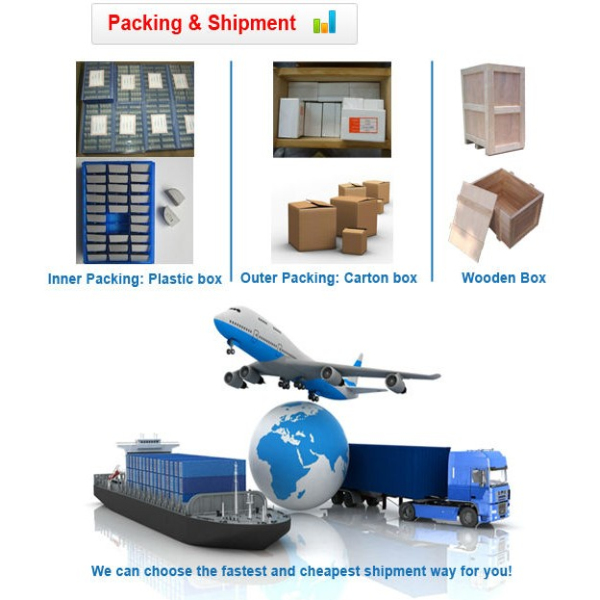

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | LS |

| Material: | PET |

| Type: | Stretch Film |

| Usage: | Packaging Film |

| Feature: | Moisture Proof |

| Processing Type: | Multiple Extrusion |

| Transparency: | Transparent |

| Production Capacity: | 1000Ton/Month |

| Packing: | Carton Box ,Pallet |

| Delivery Date: | It depends on QTY |

Product Description

Polyester Film

PET FILM

Product Description:

PET film is used successfully in a wide range of applications, due to its excellent combination of optical, physical, mechanical, thermal, and chemical properties, as well as its unique versatility.

Characteristics:

1). Optically brilliant, clear appearance

2). Unequaled mechanical strength and toughness

3). Excellent dielectric properties

4). Good flatness and coefficient of friction (COF)

5). Tear-resistant and puncture-resistant characteristics

6). Wide range of thickness 7 micron up to 100 micron

7). Excellent dimensional stability over a wide range of temperatures

8). Very good resistance to most common solvents, moisture, oil, and grease

9). Excellent barrier against a wide range of gases.

10).Widely use for packaging, printing, laminating ,metalizing , decoration , electrical insulation.

Specification | ||||||

Thickness | Length | Width | Core size | |||

10~50 µm | 325mm~2500mm | 3", 6" | ||||

*) Other specifications on request. The typical lengths of reel roll equal to 12 µm film roll lengths are 6000m, 12000m, 18000m,24000m and 36000m. | ||||||

The film is processed by three layer co-extrusion. Low heat shrinkage. High combination with multiple resin. High tensile strength. One side corona treatment is available. Stable quality. | ||||||

Physical Property | ||||||

Properties | Unit | Typical Value | Scope | Method | ||

Thickness | TD | µm | tolerance±4% | 12±0.2 | DIN 53370 | |

Tensile Strength | MD | N/mm2 | >200 | 100~235 | ASTM D882 | |

TD | N/mm2 | >220 | 245~280 | ASTM D882 | ||

Elongation | MD | % | >100 | 130~160 | ASTM D882 | |

TD | % | >100 | 105~125 | ASTM D882 | ||

E Module | MD | N/mm2 | >4000 | 4000~4300 | ASTM D882 | |

TD | N/mm2 | >4200 | 4400~4800 | ASTM D882 | ||

Haze | TD | % | 2.5~3.0 | 2.5~3.0 | ASTM D1003 | |

Heat Shrinkage | MD | % | <1.55 | 1.3~1.5 | BMSTT11 | |

TD | % | <-0.1 | -0.1~-0.25 | BMSTT11 | ||

Wetting tension | TD | mN/m | >54 | 58 | ASTM D2578 | |

Remark: MD is machine direction, TD is transverse direction. The values above can not be understood as guaranteed values. They are only the basic test values for your reference. If required can be adjusted according to your requirements. Listed are the average test values token from 6.2m,6.7m and 8.7m width jumbo roll | ||||||

Process:

Certification :

Shipping Way :