Magnetic receptive sheet Ferrous sheet Flexible iron sheet used with flexible magnet as a pair

| Min. Order: | 100 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | Paypal, L/C, D/P, D/A, T/T, WU |

| Supply Ability: | 2,000 tons/month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Rubber Coated Disc Permanent Neodymium Magnet With A Countersunk Hole In The Center, Neodymium Magnet / Block Shaped Permanent Magnet / N52 Sintered Magnet Block Supplier, Neodymium Permanent Magnet Arc Magnet / Strong Neodymium Segment Magnet For Permanent Magnet Motors And Pumps, China Rare Earth Neodymium Ring Magnet Offered At Very Competitive Price N38 Grade, Neodymium Ring Magnet / Sintered NdFeB Magnet / Neodymium Iron Boron Magnet China Manufacturer |

Product Detail

| Model No.: | RS-FIS |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Shape: | Sheet |

| Type: | Soft |

| Brand Name: | Risheng |

| Material: | Flexible iron sheet |

| Thickness: | 0.3mm-1.5mm |

| Width: | Up to 1200mm |

| Surface: | Plain, Adhesive, PVC |

| Coating: | UV |

| Production Capacity: | 2,000 tons/month |

| Packing: | Standard Seaway Packaging |

| Delivery Date: | 12-15 days a 20' container |

Product Description

Flexible iron sheet is made by mixing iron powder with synthetic rubber or plastic (CPE etc.). It is flexible and has the characteristic of flexible magnetic sheeting. It is easily cut, bent, twisted, coiled, or be machined into almost any shape without damaging.

Flexible iron sheet is not a magnet, but used to creat a magnetic receptive face. It is treated as metal base for flexible magnetic sheeting or other magnets.

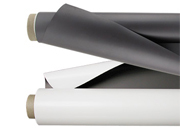

Sizes available

The standard sizes are materials with thickness(0.4mm, 0.5mm, 0.75mm, 1.5mm), width(620mm, 1000mm,1200mm) and length(15m, 30.5m). Special sizes could be easily produced upon request with limitations : Thickness: 0.15mm-8mm; Width: up to 1000mm wide. Length: up to 620m.

Surface Lamination

We are able to laminate various decorative material onto the faces of Flexible iron sheet, White PVC vinyl, Colourful PVC vinyl, PP vinyl, Double-sided self adhensive, Dry wipe finish, etc. Once the front face is laminated with any material, the other face would always be coated with UV coating.

Working temperature & Flexibility

The working temperature is recommended from -26 °C to 71 °C . At 20 °C , the materials above can be coiled to a 1/2''(12.7mm) radius without cracking.