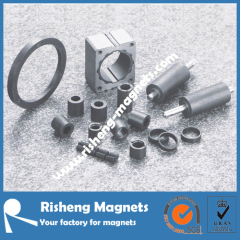

complicated shapes NdFeB powder adding adhesives Bonded NdFeB permanent magnet

| Min. Order: | 10 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 100ton/month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Rubber Coated Disc Permanent Neodymium Magnet With A Countersunk Hole In The Center, Neodymium Magnet / Block Shaped Permanent Magnet / N52 Sintered Magnet Block Supplier, Neodymium Permanent Magnet Arc Magnet / Strong Neodymium Segment Magnet For Permanent Magnet Motors And Pumps, China Rare Earth Neodymium Ring Magnet Offered At Very Competitive Price N38 Grade, Neodymium Ring Magnet / Sintered NdFeB Magnet / Neodymium Iron Boron Magnet China Manufacturer |

Product Detail

| Model No.: | RS-BN |

|---|---|

| Means of Transport: | International Express (UPS, Ocean, Air |

| Shape: | Others |

| Application: | Others |

| Type: | Others |

| Composite: | Neodymium Magnet |

| Brand Name: | Risheng |

| Material: | Neodymium Magnet |

| Grade: | BNP-3, BNP-6, BNP-8, BNP-8SR, BNP-9H, BNP-10, BNP-11, BNP-12L |

| Shape: | Disc, Ring, Block, Cylinder, Shpere and other shapes can be custom produced upon your requests. |

| Coating: | Grey Epoxy, Black Epoxy, and etc. |

| Production Capacity: | 100ton/month |

| Packing: | Standard Seaway Packing and Airway Packing |

| Delivery Date: | About 30 days according to different quantities |

Product Description

Bonded NdFeB

Introduction: made by powder metallurgy, chemical composition: Nd2Fe14B.

Advantage

High remanence, high coercivity, high magnetic energy product, high performance price ratio, easy processing of various size and the minimum specifications.

Disadvantage

The corrosion resistance of surface coating or plating is low.

Characteristics:

1) Higher Magnet Property: he magnet property of bonded NdFeB magnet is between that of sintered NdFeB and ferrite, and with good consistency and stability.

2) Large Freeness of Product Shapes and High Precision of Dimension: the magnet shape and dimension are decided by the tooling, like ring, segment, block, etc., without further sintering and mechanical machining processes.

3) Good Corrosion Resistance: after electrodeposited or through other special treatments, it can be used under normal or unfavorable environment conditions for a long time.

4) Diverse magnetization: Multi-pole magnetization and screw angle magnetization are available, and the field distribution could be square, sinusoid and so on.

5) It has high production efficiency, suitable for mass production.

Field of application

Bonded NdFeB permanent magnet material is composed of NdFeB powder adding adhesives. Since successfully invented in 1988, the material developed rapidly, and the production has doubled. As a kind of high performance permanent magnet materials, it conforms to the development trend of contemporary electronic products in short, small, light, thin direction.

The production and application of bonded NdFeB permanent magnet materials is late, so it is not widely used and the use amount is small. Mainly used in office automation equipment, electrical machinery, audio-visual equipment, instrumentation, motors and a measuring machine. In the fields of mobile phone, CD-ROM, DVD-ROM drive motor, hard disk spindle motor HDD, other micro DC motor and automation instrumentation, the application is common. The proportion of China's bonded NdFeB permanent magnet materials' application in recent years: computer accounted for 62%, the electronics industry accounted for 7%, office automation equipment accounted for 8%, cars accounted for 7%, appliances accounted for 7%, others accounted for 9%.

Compared with sintered magnet, it can be formed at one time, without the need of two processing, and can be made into various complex shapes of magnet, which sintered magnets can not achieve, it can greatly reduce the volume and weight of the motor.

Application:

The bonded NdFeB magnet is mainly used for all kinds of micro–miniature motors, such as spindle motor, stepping motor, synchronous motor, DC motor and brushless DC motor.