N45SH Neodymium Arc Magnets Permanent Neodymium Elevator Motor Magnets

| Min. Order: | 10 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, PayPal, T/T, WU |

| Supply Ability: | 100ton/month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Rubber Coated Disc Permanent Neodymium Magnet With A Countersunk Hole In The Center, Neodymium Magnet / Block Shaped Permanent Magnet / N52 Sintered Magnet Block Supplier, Neodymium Permanent Magnet Arc Magnet / Strong Neodymium Segment Magnet For Permanent Magnet Motors And Pumps, China Rare Earth Neodymium Ring Magnet Offered At Very Competitive Price N38 Grade, Neodymium Ring Magnet / Sintered NdFeB Magnet / Neodymium Iron Boron Magnet China Manufacturer |

Product Detail

| Model No.: | RS-Arc 05 |

|---|---|

| Means of Transport: | International Express (UPS, Ocean, Air |

| Application: | Industrial Magnet |

| Type: | Permanent |

| Composite: | Rare Earth Magnet |

| Brand Name: | Risheng Magnets |

| Material: | Neodymium Magnet |

| Grade: | Can be custom produced from N35 grade to 33AH grade |

| Shape: | Disc, Ring, Block, Cylinder, Shpere and other shapes can be custom produced upon your requests. |

| Coating: | Ni-Cu-Ni, Zn, Black Epoxy, and etc. |

| Production Capacity: | 100ton/month |

| Packing: | Standard Seaway Packing and Airway Packing |

| Delivery Date: | About 30 days according to different quantities |

Product Description

Neodymium magnets are the third generation of rare earth magnets, which are composed of Neodymium, Iron, Boron and a few transition metals. They have high remanence, high coercive force, high energy product, and high performance. Currently Neodymium magnets are the strongest magnets available in the world.

The Magnetic Properties of N45SH Neodymium Arc Magnets Permanent Neodymium Elevator Motor Magnets:

| Magnetic Properties of Neodymium Magnets | |||||

| Grade | Residual Induction | Coercive Force | Intrinsic Coercive Force | Maximum Energy Product | Maximum Working Temperature |

| Br | Hcb | Hcj | (BH)max | Tw | |

| mT | kA/m | kA/m | kJ/m3 | ||

| [kGs] | [kOe] | [kOe] | [MGOe] | ||

| N35 | 1170-1220 | ≥868 | ≥955 | 263-287 | 80° |

| [11.7-12.2] | [≥10.9] | [≥12] | [33-36] | ||

| N38 | 1220-1250 | ≥899 | ≥955 | 287-310 | 80° |

| [12.2-12.5] | [≥11.3] | [≥12] | [36-39] | ||

| N40 | 1250-1280 | ≥907 | ≥955 | 302-326 | 80° |

| [12.5-12.8] | [≥11.4] | [≥12] | [38-41] | ||

| N42 | 1280-1320 | ≥915 | ≥955 | 318-342 | 80° |

| [12.8-13.2] | [≥11.5] | [≥12] | [40-43] | ||

| N45 | 1320-1380 | ≥923 | ≥955 | 342-366 | 80° |

| [13.2-13.8] | [≥11.6] | [≥12] | [43-46] | ||

| N48 | 1380-1420 | ≥923 | ≥955 | 366-390 | 80° |

| [13.8-14.2] | [≥11.6] | [≥12] | [46-49] | ||

| N50 | 1400-1450 | ≥796 | ≥876 | 382-406 | 80° |

| [14.0-14.5] | [≥10.0] | [≥11] | [48-51] | ||

| N52 | 1430-1480 | ≥796 | ≥876 | 398-422 | 80° |

| [14.3-14.8] | [≥10.0] | [≥11] | [50-53] | ||

| 30M | 1080-1130 | ≥805 | ≥1114 | 223-247 | 100° |

| [10.8-11.3] | [≥10.1] | [≥14] | [28-31] | ||

| 33M | 1130-1170 | ≥836 | ≥1114 | 247-263 | 100° |

| [11.3-11.7] | [≥10.5] | [≥14] | [31-33] | ||

| 35M | 1170-1220 | ≥868 | ≥1114 | 263-287 | 100° |

| [11.7-12.2] | [≥10.9] | [≥14] | [33-36] | ||

| 38M | 1220-1250 | ≥899 | ≥1114 | 287-310 | 100° |

| [12.2-12.5] | [≥11.3] | [≥14] | [36-39] | ||

| 40M | 1250-1280 | ≥923 | ≥1114 | 302-326 | 100° |

| [12.5-12.8] | [≥11.6] | [≥14] | [38-41] | ||

| 42M | 1280-1320 | ≥955 | ≥1114 | 318-342 | 100° |

| [12.8-13.2] | [≥12.0] | [≥14] | [40-43] | ||

| 45M | 1320-1380 | ≥995 | ≥1114 | 342-366 | 100° |

| [13.2-13.8] | [≥12.5] | [≥14] | [43-46] | ||

| 48M | 1370-1430 | ≥1027 | ≥1114 | 366-390 | 100° |

| [13.7-14.3] | [≥12.9] | [≥14] | [46-49] | ||

| 50M | 1400-1450 | ≥1033 | ≥1114 | 382-406 | 100° |

| [14.0-14.5] | [≥13.0] | [≥14] | [48-51] | ||

| 35H | 1170-1220 | ≥868 | ≥1353 | 263-287 | 120° |

| [11.7-12.2] | [≥10.9] | [≥17] | [33-36] | ||

| 38H | 1220-1250 | ≥899 | ≥1353 | 287-310 | 120° |

| [12.2-12.5] | [≥11.3] | [≥17] | [36-39] | ||

| 40H | 1250-1280 | ≥923 | ≥1353 | 302-326 | 120° |

| [12.5-12.8] | [≥11.6] | [≥17] | [38-41] | ||

| 42H | 1280-1320 | ≥955 | ≥1353 | 318-342 | 120° |

| [12.8-13.2] | [≥12.0] | [≥17] | [40-43] | ||

| 45H | 1320-1360 | ≥963 | ≥1353 | 342-366 | 120° |

| [13.2-13.6] | [≥12.1] | [≥17] | [43-46] | ||

| 48H | 1370-1430 | ≥995 | ≥1353 | 366-390 | 120° |

| [13.7-14.3] | [≥12.5] | [≥17] | [46-49] | ||

| 35SH | 1170-1220 | ≥876 | ≥1592 | 263-287 | 150° |

| [11.7-12.2] | [≥11.0] | [≥20] | [33-36] | ||

| 38SH | 1220-1250 | ≥907 | ≥1592 | 287-310 | 150° |

| [12.2-12.5] | [≥11.4] | [≥20] | [36-39] | ||

| 40SH | 1250-1280 | ≥939 | ≥1592 | 302-326 | 150° |

| [12.5-12.8] | [≥11.8] | [≥20] | [38-41] | ||

| 42SH | 1280-1320 | ≥987 | ≥1592 | 318-342 | 150° |

| [12.8-13.2] | [≥12.4] | [≥20] | [40-43] | ||

| 45SH | 1320-1380 | ≥1003 | ≥1592 | 342-366 | 150° |

| [13.2-13.8] | [≥12.6] | [≥20] | [43-46] | ||

| 28UH | 1040-1080 | ≥764 | ≥1990 | 207-231 | 180° |

| [10.4-10.8] | [≥9.6] | [≥25] | [26-29] | ||

| 30UH | 1080-1130 | ≥812 | ≥1990 | 223-247 | 180° |

| [10.8-11.3] | [≥10.2] | [≥25] | [28-31] | ||

| 33UH | 1130-1170 | ≥852 | ≥1990 | 247-271 | 180° |

| [11.3-11.7] | [≥10.7] | [≥25] | [31-34] | ||

| 35UH | 1170-1220 | ≥860 | ≥1990 | 263-287 | 180° |

| [11.7-12.2] | [≥10.8] | [≥25] | [33-36] | ||

| 38UH | 1220-1250 | ≥876 | ≥1990 | 287-310 | 180° |

| [12.2-12.5] | [≥11.0] | [≥25] | [36-39] | ||

| 40UH | 1250-1280 | ≥899 | ≥1990 | 302-326 | 180° |

| [12.5-12.8] | [≥11.3] | [≥25] | [38-41] | ||

| 28EH | 1040-1080 | ≥780 | ≥2388 | 207-231 | 200° |

| [10.4-10.8] | [≥9.8] | [≥30] | [26-29] | ||

| 30EH | 1080-1130 | ≥812 | ≥2388 | 223-247 | 200° |

| [10.8-11.3] | [≥10.2] | [≥30] | [28-31] | ||

| 33EH | 1130-1170 | ≥876 | ≥2388 | 247-271 | 200° |

| [11.3-11.7] | [≥10.5] | [≥30] | [31-34] | ||

| 35EH | 1170-1220 | ≥876 | ≥2388 | 263-287 | 200° |

| [11.7-12.2] | [≥11.0] | [≥30] | [33-36] | ||

| 38EH | 1220-1250 | ≥899 | ≥2388 | 287-310 | 200° |

| [12.2-12.5] | [≥11.3] | [≥30] | [36-39] | ||

| 28AH | 1040-1080 | ≥787 | ≥2624 | 207-231 | 220° |

| [10.4-10.8] | [≥9.9] | [≥33] | [26-29] | ||

| 30AH | 1080-1130 | ≥819 | ≥2624 | 223-247 | 220° |

| [10.8-11.3] | [≥10.3] | [≥33] | [28-31] | ||

| 33AH | 1130-1170 | ≥843 | ≥2624 | 247-271 | 220° |

| [11.3-11.7] | [≥10.6] | [≥33] | [31-34] | ||

The Physical Properties of N45SH Neodymium Arc Magnets Permanent Neodymium Elevator Motor Magnets:

| Parameters | Units | Indicators |

| Density | g/cm³ | ≥7.3 |

| Home temperature | ℃ | 310-340 |

| BrReversible temperature coefficient | ℃/% | -0.100~-0.130 |

| HcjReversible temperature coefficient | ℃/% | 0.40~0.70 |

| Compressive strength | N/mm2 | 1050 |

| Bending strength | N/mm2 | 250 |

| Tensile strength | N/mm2 | 80 |

| Webster Hardness | 600 | |

| Coefficient of thermal expansion(20 to 200℃) | 10-6/k | ∥5⊥-1.5 |

| Specific heat | J/(Kg.K) | 460 |

| Thermal conductivity | W/(m.K) | 9 |

| Resistivity | μΩ.cm | 150 |

The Surface Coatings of N45SH Neodymium Arc Magnets Permanent Neodymium Elevator Motor Magnets:

| Surface Coating | Coating Method | Coating thickness(m) | Coating Color | Coating features |

| Nickel | plating | ≥5 | Yellow | Corrosion resistance strong,with outstanding resistance to high temperature and humidity capabilities |

| zinc | plating | ≥5 | Silvery white | Has strong corrosion resistance,anti-salt spray test ability . |

| gold | plating | ≥5 | gold | Has outstanding resistance to high temperature capability,corrosion resistance,good resistance to color change ablity |

| Ni-Cu-Ni | plating | 15-30 | sliver | strong corrosion resistance |

| Epoxy | Electrophoresis | 15-20 | Black/grey | strong corrosion resistance,outstanding resistance to salt spray,strong resistance to high temperature, high humidity capacity |

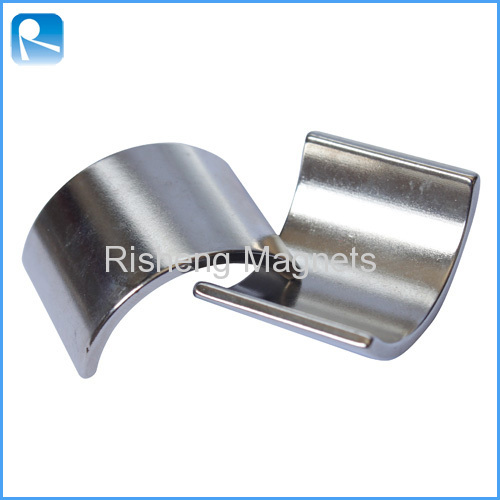

Picture of N45SH Neodymium Magnets Arc Permanent Elevator Motor Neodymium Magnets:

N45SH Permanent magnet motor wiht NiCuNi coating:

Different shapes of neodymium magnets for sale:

The Application of N45SH Neodymium Magnets Arc Permanent Elevator Motor Neodymium Magnets:

Neodymium Permanent Magnet can be widely used in the electro-acousticfields,such as loud speaker, headphone, earphone, stage sound device, alarm, microphone and so on. With the good performance, our magnets can provide sound equipments with excellent sensitiveness and susceptibility.

If you would like, please do not hesitate to contact us,we will supply professional magnet and best service for you.