Neodymium Magnets Neodym magnets NdFeB magnets Strong magnets

| Min. Order: | 10 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 100ton/month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Rubber Coated Disc Permanent Neodymium Magnet With A Countersunk Hole In The Center, Neodymium Magnet / Block Shaped Permanent Magnet / N52 Sintered Magnet Block Supplier, Neodymium Permanent Magnet Arc Magnet / Strong Neodymium Segment Magnet For Permanent Magnet Motors And Pumps, China Rare Earth Neodymium Ring Magnet Offered At Very Competitive Price N38 Grade, Neodymium Ring Magnet / Sintered NdFeB Magnet / Neodymium Iron Boron Magnet China Manufacturer |

Product Detail

| Model No.: | RS-NEO |

|---|---|

| Means of Transport: | International Express (UPS, Ocean, Air |

| Application: | Industrial Magnet |

| Type: | Permanent |

| Composite: | Neodymium Magnet |

| Brand Name: | Risheng |

| Material: | Neodymium, Iron, Boron |

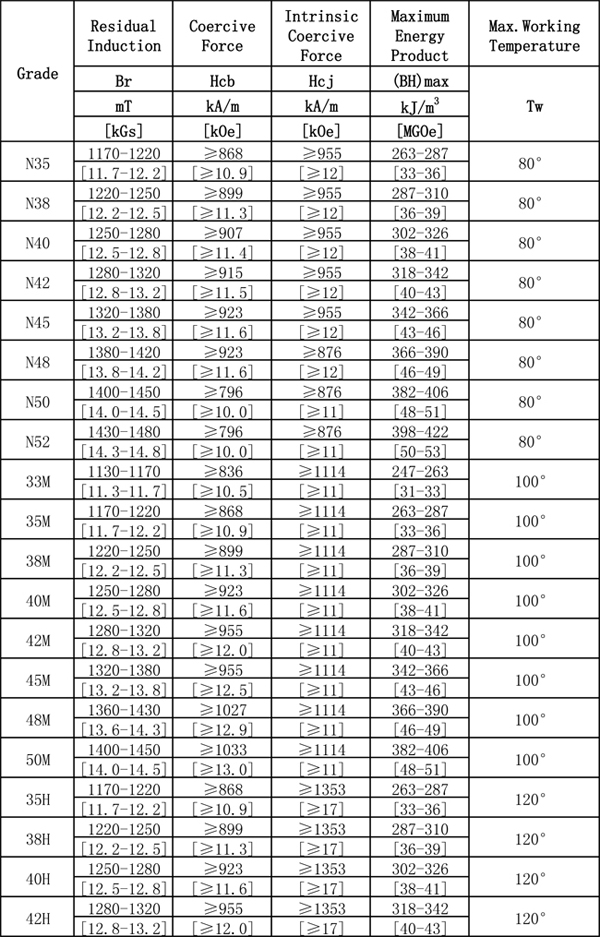

| Grade: | N35, N38, N40, N42, N45, N48, N50, N52 |

| Shape: | Disc, Ring, Block, Cylinder, Shpere and other shapes can be custom produced upon your requests. |

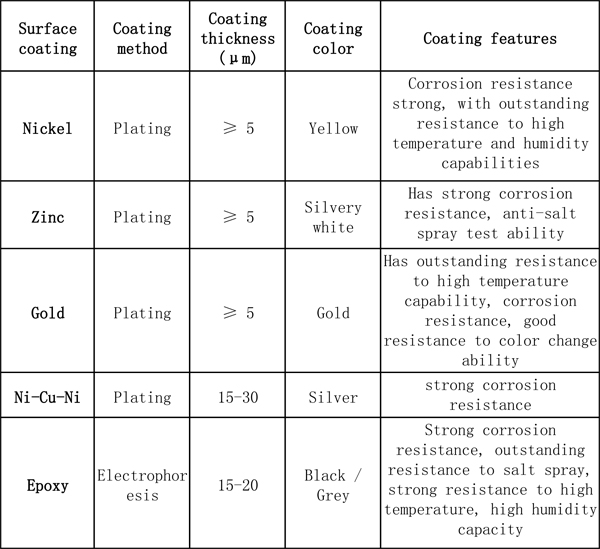

| Coating: | Ni-Cu-Ni, Zn, Black Epoxy, etc. |

| Production Capacity: | 100ton/month |

| Packing: | Standard Seaway Packing and Airway Packing |

| Delivery Date: | About 30 days according to different quantities |

Product Description

Production Application of Neodymium Magnets:

General Info of Neodymium Magnets:

Neodymium magnets (aka NdFeB magnets, Neodym magnets, Neo magnets), the third generation of rare earth permanent magnet, are composed of Neodymium, Iron, Boron and a few transition metals. They have high remanence,high coercive force, high energy product, and high performance /cost. Currently Neodymium magnets are the strongest magnets available in the world.

Neodymium, Iron, Boron and a few transition metals will be made into the Neodymium powder, then fine Neodymium powder will be compacted in a die and sintered, fusing thepowder into a solid material. There are 2 forms of pressing: die pressing and isostatic pressing. Sintered parts normally need some finish machining in order to meet final tolerances.

The corrosion resistance of Neodymium magnets is considered poor. Surface coating or plating is therefore highly recommended for Neodymium magnets. All kinds of surface coating are available, like Nickel, Zn, Ni-Cu-Ni, Gold, Silver, Sn, Chrome. We also applied special surface protection to Neodymium magnets, like ABS coating, Rubber coating, PTFE(Telfon) coating, stainless steel case, etc.

Neodymium magnets require extremely high magnetizing fields, and can be magnetized in any direction as long as it is aligned properly. Neodymium magnets are mechanically weak, and magnetically very strong. They should be packed properly in order to help user to use and handle them.

Production process and Equipments of Neodymium Magnets:

Magnetic Properties of Neodymium Magnets:

Physical Properties of Neodymium Magnets:

Surface Coatings for Neodymium Magnets: