Irregular Sintered Neodymium Magnet Half - Circle Shaped Irregular NdFeB Magnet

| Min. Order: | 10 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 100ton/month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Rubber Coated Disc Permanent Neodymium Magnet With A Countersunk Hole In The Center, Neodymium Magnet / Block Shaped Permanent Magnet / N52 Sintered Magnet Block Supplier, Neodymium Permanent Magnet Arc Magnet / Strong Neodymium Segment Magnet For Permanent Magnet Motors And Pumps, China Rare Earth Neodymium Ring Magnet Offered At Very Competitive Price N38 Grade, Neodymium Ring Magnet / Sintered NdFeB Magnet / Neodymium Iron Boron Magnet China Manufacturer |

Product Detail

| Model No.: | RS-I02 |

|---|---|

| Means of Transport: | Fedex, Ocean, Air |

| Application: | Industrial Magnet |

| Shape: | Block |

| Type: | Permanent |

| Composite: | Neodymium Magnet |

| Brand Name: | Risheng |

| Material: | Neodymium Magnet |

| Grade: | N35 - N52 |

| Shape: | The shape is custom produced according to our customers' requirements |

| Coating: | NiCuNi, Zn, gold black epoxy, and etc. |

| Production Capacity: | 100ton/month |

| Packing: | Standard Seaway Packing and Airway Packing |

| Delivery Date: | About 30 days according to different quantities |

Product Description

Sintered Neodymium rare earth magnets are the strongest magnets in the world up to date, with high flux density and high coercivity, the range of energy product is 33--53MGOe. Sintered NdFeB magnets are anisotropic and can only be magnetized in one direction.

Sintered Neodymium rare earth magnets are widely used in Motors, Separators, lifting, sensors, loudspeakers, MRI, VCM, and other electronics, automation systems.

1. Produced by powder metallurgical method with chemical composition of Nd2Fe14B;

2. Excellent cost to performance ratio;

3. Reasonable temperature stability;

4. Very brittle & hard;

5. High resistance to be demagnetized;

6. Poor corrosion resistance to be corrupted;

7. Not suitable for application which is exposed in high temperature conditions.

8. Shapes: irregular

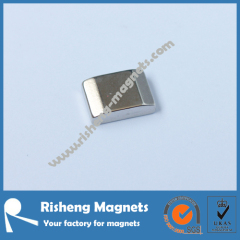

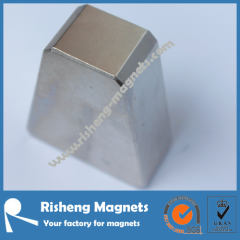

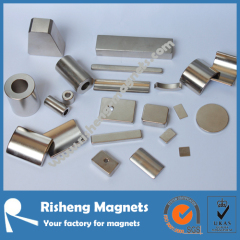

Pictures of Irregular Sintered Neodymium Magnet Half - Circle Shaped Irregular NdFeB Magnet:

9. Available Grades of Irregular Sintered Neodymium Magnet Half - Circle Shaped Irregular NdFeB Magnet:

| Grade | Residual Induction | Coercive Force | Intrinsic Coercive Force | Maximum Energy Product | Maximum Working Temperature |

| Br | Hcb | Hcj | (BH)max | Tw | |

| mT | kA/m | kA/m | kJ/m3 | ||

| [kGs] | [kOe] | [kOe] | [MGOe] | ||

| N35 | 1170-1220 | ≥868 | ≥955 | 263-287 | 80° |

| [11.7-12.2] | [≥10.9] | [≥12] | [33-36] | ||

| N38 | 1220-1250 | ≥899 | ≥955 | 287-310 | 80° |

| [12.2-12.5] | [≥11.3] | [≥12] | [36-39] | ||

| N40 | 1250-1280 | ≥907 | ≥955 | 302-326 | 80° |

| [12.5-12.8] | [≥11.4] | [≥12] | [38-41] | ||

| N42 | 1280-1320 | ≥915 | ≥955 | 318-342 | 80° |

| [12.8-13.2] | [≥11.5] | [≥12] | [40-43] | ||

| N45 | 1320-1380 | ≥923 | ≥955 | 342-366 | 80° |

| [13.2-13.8] | [≥11.6] | [≥12] | [43-46] | ||

| N48 | 1380-1420 | ≥923 | ≥955 | 366-390 | 80° |

| [13.8-14.2] | [≥11.6] | [≥12] | [46-49] | ||

| N50 | 1400-1450 | ≥796 | ≥876 | 382-406 | 80° |

| [14.0-14.5] | [≥10.0] | [≥11] | [48-51] | ||

| N52 | 1430-1480 | ≥796 | ≥876 | 398-422 | 80° |

| [14.3-14.8] | [≥10.0] | [≥11] | [50-53] | ||

| 30M | 1080-1130 | ≥805 | ≥1114 | 223-247 | 100° |

| [10.8-11.3] | [≥10.1] | [≥14] | [28-31] | ||

| 33M | 1130-1170 | ≥836 | ≥1114 | 247-263 | 100° |

| [11.3-11.7] | [≥10.5] | [≥14] | [31-33] | ||

| 35M | 1170-1220 | ≥868 | ≥1114 | 263-287 | 100° |

| [11.7-12.2] | [≥10.9] | [≥14] | [33-36] | ||

| 38M | 1220-1250 | ≥899 | ≥1114 | 287-310 | 100° |

| [12.2-12.5] | [≥11.3] | [≥14] | [36-39] | ||

| 40M | 1250-1280 | ≥923 | ≥1114 | 302-326 | 100° |

| [12.5-12.8] | [≥11.6] | [≥14] | [38-41] | ||

| 42M | 1280-1320 | ≥955 | ≥1114 | 318-342 | 100° |

| [12.8-13.2] | [≥12.0] | [≥14] | [40-43] | ||

| 45M | 1320-1380 | ≥995 | ≥1114 | 342-366 | 100° |

| [13.2-13.8] | [≥12.5] | [≥14] | [43-46] | ||

| 48M | 1370-1430 | ≥1027 | ≥1114 | 366-390 | 100° |

| [13.7-14.3] | [≥12.9] | [≥14] | [46-49] | ||

| 50M | 1400-1450 | ≥1033 | ≥1114 | 382-406 | 100° |

| [14.0-14.5] | [≥13.0] | [≥14] | [48-51] | ||

| 35H | 1170-1220 | ≥868 | ≥1353 | 263-287 | 120° |

| [11.7-12.2] | [≥10.9] | [≥17] | [33-36] | ||

| 38H | 1220-1250 | ≥899 | ≥1353 | 287-310 | 120° |

| [12.2-12.5] | [≥11.3] | [≥17] | [36-39] | ||

| 40H | 1250-1280 | ≥923 | ≥1353 | 302-326 | 120° |

| [12.5-12.8] | [≥11.6] | [≥17] | [38-41] | ||

| 42H | 1280-1320 | ≥955 | ≥1353 | 318-342 | 120° |

| [12.8-13.2] | [≥12.0] | [≥17] | [40-43] | ||

| 45H | 1320-1360 | ≥963 | ≥1353 | 342-366 | 120° |

| [13.2-13.6] | [≥12.1] | [≥17] | [43-46] | ||

| 48H | 1370-1430 | ≥995 | ≥1353 | 366-390 | 120° |

| [13.7-14.3] | [≥12.5] | [≥17] | [46-49] | ||

| 35SH | 1170-1220 | ≥876 | ≥1592 | 263-287 | 150° |

| [11.7-12.2] | [≥11.0] | [≥20] | [33-36] | ||

| 38SH | 1220-1250 | ≥907 | ≥1592 | 287-310 | 150° |

| [12.2-12.5] | [≥11.4] | [≥20] | [36-39] | ||

| 40SH | 1250-1280 | ≥939 | ≥1592 | 302-326 | 150° |

| [12.5-12.8] | [≥11.8] | [≥20] | [38-41] | ||

| 42SH | 1280-1320 | ≥987 | ≥1592 | 318-342 | 150° |

| [12.8-13.2] | [≥12.4] | [≥20] | [40-43] | ||

| 45SH | 1320-1380 | ≥1003 | ≥1592 | 342-366 | 150° |

| [13.2-13.8] | [≥12.6] | [≥20] | [43-46] | ||

| 28UH | 1040-1080 | ≥764 | ≥1990 | 207-231 | 180° |

| [10.4-10.8] | [≥9.6] | [≥25] | [26-29] | ||

| 30UH | 1080-1130 | ≥812 | ≥1990 | 223-247 | 180° |

| [10.8-11.3] | [≥10.2] | [≥25] | [28-31] | ||

| 33UH | 1130-1170 | ≥852 | ≥1990 | 247-271 | 180° |

| [11.3-11.7] | [≥10.7] | [≥25] | [31-34] | ||

| 35UH | 1170-1220 | ≥860 | ≥1990 | 263-287 | 180° |

| [11.7-12.2] | [≥10.8] | [≥25] | [33-36] | ||

| 38UH | 1220-1250 | ≥876 | ≥1990 | 287-310 | 180° |

| [12.2-12.5] | [≥11.0] | [≥25] | [36-39] | ||

| 40UH | 1250-1280 | ≥899 | ≥1990 | 302-326 | 180° |

| [12.5-12.8] | [≥11.3] | [≥25] | [38-41] | ||

| 28EH | 1040-1080 | ≥780 | ≥2388 | 207-231 | 200° |

| [10.4-10.8] | [≥9.8] | [≥30] | [26-29] | ||

| 30EH | 1080-1130 | ≥812 | ≥2388 | 223-247 | 200° |

| [10.8-11.3] | [≥10.2] | [≥30] | [28-31] | ||

| 33EH | 1130-1170 | ≥876 | ≥2388 | 247-271 | 200° |

| [11.3-11.7] | [≥10.5] | [≥30] | [31-34] | ||

| 35EH | 1170-1220 | ≥876 | ≥2388 | 263-287 | 200° |

| [11.7-12.2] | [≥11.0] | [≥30] | [33-36] | ||

| 38EH | 1220-1250 | ≥899 | ≥2388 | 287-310 | 200° |

| [12.2-12.5] | [≥11.3] | [≥30] | [36-39] | ||

| 28AH | 1040-1080 | ≥787 | ≥2624 | 207-231 | 220° |

| [10.4-10.8] | [≥9.9] | [≥33] | [26-29] | ||

| 30AH | 1080-1130 | ≥819 | ≥2624 | 223-247 | 220° |

| [10.8-11.3] | [≥10.3] | [≥33] | [28-31] | ||

| 33AH | 1130-1170 | ≥843 | ≥2624 | 247-271 | 220° |

| [11.3-11.7] | [≥10.6] | [≥33] | [31-34] |

10. Sizes: Customized;

11. Tolerance: (+/-0.1mm),Customized;

12.Coatings of Neodymium irregular magnet,: Passivation, Nickel, Zinc, Tin, Aurum, Copper, Epoxy, Chemical, etc.

13. Applications of Neodymium irregular magnet,: Toys, Packing boxes, Micro-special electric machinery, Permanent-magnet instrumental meters, Electronic industry, Nuclear magnetic resonance equipments, Magnetic suspension system, Magnetic transmission gears, Magnet therapy equipment, Sorption, ads, Books managements, Teaching tools, Office automation , Magnetic separators, Copiers, Synchrotrons, Radiation sources, Nuclear industry, Agriculture industrial, Detection earthquake, and so on.