Full-Auto High-Speed Varnishing Machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | L/C, T/T |

| Supply Ability: | 23 sets / month |

| Place of Origin: | Guangdong |

Company Profile

| Location: | Shantou, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Inkjet Printer, Flute Laminating Machine, UV Coating Machine, Laminating Machine, Printing Machine |

Product Detail

| Model No.: | HSG-120 |

|---|---|

| Means of Transport: | Ocean |

| Processing: | Coating Machine |

| Automatic Grade: | Automatic |

| Type: | General |

| Usage: | Outer |

| Packaging: | Others |

| Brand Name: | OUTEX |

| Production Capacity: | 23 sets / month |

| Packing: | Equipments are packaged by fastening at the base with dust proof film. |

| Delivery Date: | 45 days after deposit receipt |

Product Description

Product features: The maximum speed can reach 90 meter / minute. With a perfect combination of new appearance design and baking paint craft, it replaces the traditional manual glazing machines and is automatic control, high speed and easy to operate. Because it is manipulated by one person, it saves the labor cost and reduces labor intensity. The new design of the way of drying solves energy problems. And its special continuous paper feeding and collecting devices makes it more efficient.

II. Specification

III. Main Components

Main components: Automatic Paper Feeding Machine +Paper Powder Removing Machine +Paper Glazing Machine+ Paper Collecting Machine

I. Main Functions and Features:

1. Automatic paper feeding machine: With an accurate feeder, the new designed glazing machine automatically and continuously feeds paper, ensuring the smooth conveying of different sizes' paper. The paper suction system is controlled by a simple and reliable rotary gas valve. The suction nozzle, cam and hold-down device are reasonably designed for accurate matching operations. Besides, this machine is provided with an emergency shut down device, guard boards and double-sheet detector. No adjustment is required for changeover between thick and thin paper. The paper feeding speed of the feeder reaches 10,000 sheets per hour. The unique uninterrupted paper feeding unit ensures continuous production.

2. Powder removing machine (optional): The glazing machine uses water to effectively remove printing powder, and the paper will then pass the drying tunnel to be dried. This powder removing device is the same as the oil head which can also be used in the first course of paper glazing and it fits for water-based, oil-based, etc.

3. Glazing part: With special glazing rollers, the three-roller design is reliable and durable. The adjustment of the glazing roller of the new glazing machine is changed into one-direction adjustment so that it can be operated more convenient.

4. Drying tunnel: This brand new infrared ray drying system has technical improvements — it reasonably matches infrared ray drying system with air drying and cooling system and finally finds a ways to rapidly dry paper. Comparing with the traditional IR heating, this one saves over 35% energy and increases production efficiency. The conveying belts are also redesigned. The original multiple belts are changed into the Teflon net so that it is suitable for different sizes' paper in the production process without adjusting the belts.

Picture5. Automatic paper collecting unit: With a vacuum suction belt, the conveying table smoothly conveys paper. The pneumatic double-side paper aligning device allows orderly and smooth delivery of paper. In addition, the system is equipped with a paper counter; its paper carrier is suspended by chains and may automatically descend by photoelectric sensor. Its unique continuous paper collecting unit increases its working efficiency.

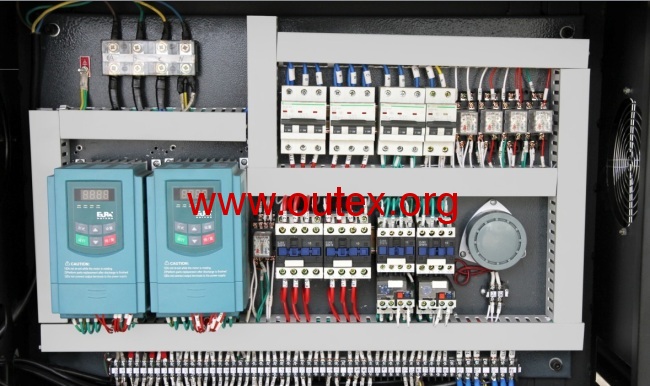

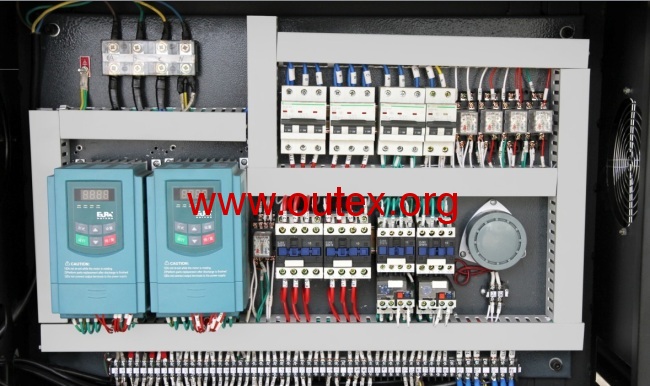

6. The advanced circuit control: Its motor adopts frequency conversion, which is stable, energy-saving and safe.

II. Specification

Configuration | withoutpowder remover | With powderremover |

Max paper size (mm) | 1200×1200 | 1200×1200 |

Min paper size (mm) | 350×400 | 350×400 |

Mechanical speed (M/min) | 25-90 (depend on drying speed) | 25-90 (depend on drying speed) |

Min paper weight (gsm) | 200 (depend on paper quality & size) | 200 (depend on paper quality & size) |

Max paper weight (gsm) | 800 | 800 |

Height of paper delivery | 110 | 110 |

Total power (kw) | 32.1KW | 42.8KW |

Gross weight (kg) | 5000 | 6500 |

External dimensions (mm) (L×W×H) | 14080×1920×1850 | 18760×1920×1850 |

III. Main Components

Components | Manufacturer |

#60 vacuum pump | Zhenjiang Tongyou Printing Machinery Co., Ltd. |

Air compressor | Youba |

1.5kw main motor | Jintai |

Bearing | Harbin Bearing Factory |

Frequency converter | Ourui |

Fan | Detong |

Counter | Taisong |