BA series hydraulic bladder accumulator(ASME standard)

| Min. Order: | 50 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 2000sets per month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Service |

Product Detail

| Model No.: | BA(TA) series |

|---|---|

| Means of Transport: | Ocean, Land |

| Product Type: | Others |

| Machine Type: | Others |

| Brand Name: | Chaori |

| material: | carbon steel |

| color: | black,as customer request |

| connection type: | thread |

| operating pressure: | 10-31.5Mpa |

| standard: | ASME |

| same as brand: | Rexroth,Parker etc. |

| Production Capacity: | 2000sets per month |

| Packing: | wooden case |

| Delivery Date: | within 35 working days |

Product Description

product name: Hydraulic accumulator(ASME standard)

hydraulic bladder accumulator(ASME standard)

1.Model code.

BA (TA) - # / # - # - #

1 2 3 4 5

1. Structure: BA-bottom dismantlement TA-top diamantlement

2. Nominal volume: 0.15gal~15gal

3. Max operating pressure: 3000psi~5000psi

4. Connection type: T threaded connection F-flanged connection

5. medium: H hydraulic oil R- emulsion W-water

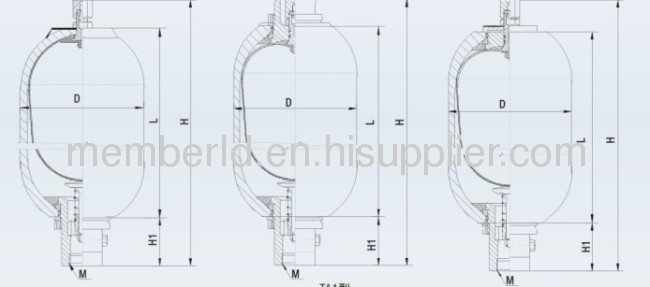

2. Structure and dimension.

| design pressure | 3000psi | 20.7Mpa |

| operating pressure | 5000psi | 34.5Mpa |

| testing pressure | 3900psi | 27Mpa |

| pressure | 6500psi | 44.9Mpa |

| meduim: | oil | nitrogen |

| operating temperature: | -4F~158F | -20~70ºC |

| charging pressure | 90% min pressure | 25% max pressure |

| connection typ: | 6L/S threaded | 9L/S flanged |

| installation | vertical | vertical |

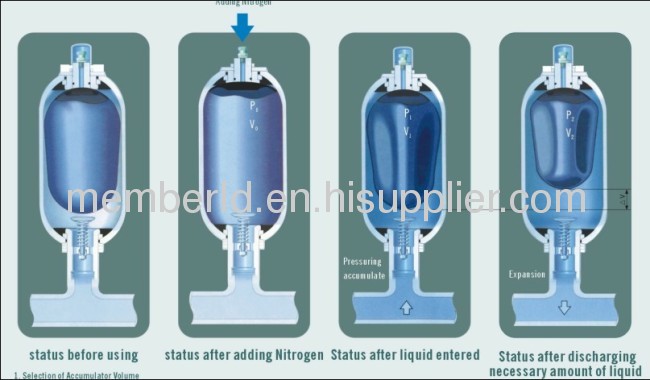

3. Working production.

We use seamless steel tube to manufacture the accumulator shell.

4.Charging of nitrogen.

(1) Accumulator shall be inspected before nitrogen is charged.

(2) Nitrogen shall be chaerged slowly to ensure the bladder be not broken by quickly charging.

(3) Oxygen,compact air or other flammable gas shall not be used.

(4) Gas charging device shall be used in charging the nitrogen.Gas charging device is inseparable part of accumulator to be used in charging,draining,measuring and adjusting the charging pressure.

5. Determining of charging presasure.

(1) Buffering impact: charging pressure shall be the norminal pressure of installation site or a little above.

(2) Absorbing fluctuation:Charging pressure shall be 60%of average pressure of fluctuation.

(3)Storage of energy:Charging pressure shall be lower than 90%of minimum working pressure and higher than 25% of maximum working pressure.