Thermal transfer film for children helmet

| Min. Order: | 800 Square Meter |

|---|---|

| Payment Terms: | T/T |

| Supply Ability: | 500000 square meter per month |

| Place of Origin: | Guangdong |

Company Profile

| Location: | Dongguan, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | 2014 China Manufacturer Heat Transfer Film For Slippers, 2014 Hot Popular 3D Vacuum Heat Transfer Machine For Slipper/egg/bowl, 2014 China Manufacture Offers Heat Transfer Film For Slippers, Double Head Skateboard Heat Transfer Machine, Full Automatic Aluminum Tube Heat Transfer Machine With Good Printing Effect |

Product Detail

| Means of Transport: | Ocean, Air |

|---|---|

| Method: | Heat Transfer Printing |

| Usage: | Others |

| Brand Name: | YIXIN |

| Application: | For children helmet/printing sheets for children helmet |

| Material Type: | Foils |

| Material: | ABS/PVC/PC |

| MOQ: | 600 square meters |

| Thickness: | 0.02mm--0.025mm |

| Max colors: | 10 color |

| Product Name: | Heat transfer film for children helmet |

| Original Place: | DongGuan |

| Method: | Heat transfer printing |

| Production Capacity: | 500000 square meter per month |

| Packing: | Polybag+drying agent+carton |

| Delivery Date: | 10-15 days |

Product Description

Aeon Printing Materials Co.,LTD which was established in 1999,is the first modern high-tech enterprise with professional heat transfer printing and plate making in China.We import advanced printing plate making equipments from USA and Germany,and we use domestic high-end heat transfer equipments also.After recent 10 years development,our business already covered all parts in the world,which has big influence in same industry.

| Specifications | ||||

| Item Name: | Thermal transfer film for children helmet | |||

| Usage | For children helmet/printing sheets for children helmet | |||

| Material | ABS | |||

| Thickness | 0.02mm--0.025mm | |||

| Delivery Time | 10~15 days | |||

| Method | Heat transfer printing | |||

| Brand Name | YiXin | |||

| Material Type | Film | |||

| MOQ | 800 square meters | |||

| Maximum colors | 10 | |||

Method for making heat transfer films:

First,cut some PET films from a big roll of PET films according to clients'electric carving plate size

Second,put the release layer on the PET films by the spreading machine,only after it becomes dry then can put on the heat transfer printing machine.Our 10 colors and 8 colors heat transfer printing machines with high-resolution can make the products look much more vivid.The pattern can print on the correct place with high efficiency,which can improve the products'grade and save much time.

Third,after printing the pattern,we will put the glue layer by spreading machine(use different glue according to different material,our glue can print on ABS\PP\PC\PVC\PE\EVA \wooden products\metal\glass\leather,etc)

Finally,cut into small rolls and have a series of checking by our QC department .Only after that then will deliver the goods.

Our heat transfer films can be widely used in plastic(ABS\PP\PC\PVC\PE\EVA )\wooden products\metal\glass\leather,etc,which can be applied in stationeries\commodity\wooden products(furnitures)\plastic products\stainless dinnerwares\EVA slippers\EVA floor mat,etc.

Our "YIXIN"heat transfer films use domestic thickest PET base films that can resist 300℃,making it easy to stamp on the glass and metal directly without any surface dealing.We are using the printing ink imported from Germany and we can offer professional ink report of environmental protection for your reference also,which you can use and sell the products without any worry.

The way to keep the film

It 's well-known that the film is very much important for the heat transfer printing.It can be a big problem for the whole production if there is some storage problem of the films.So below are some tips for how to keep the heat transfer films in good condition:

1.The film rolls need to put vertically,cannot put horizontally in case the ink layer will come out because of the pressure

2.Note for the press and throw.As the ink layer on the films will be come off easily ,the films cannot be treated rudely.We have seen some production line worker sitting on one carton of films directly in our one client's factory.It's wrong to do like that because it will damage the films easily.

3.Keep the films away from heat,it's best to keep the films in 20-40℃.

4.The films should be kept dry.Once it becomes damp,it will create gas when heated to print the products,which will make the films have chemical action.Therefore,the films need to be kept in cool, well-ventilated and dry place to remain in the best condition.

Heat transfer printing children helmet

Hot stamping foil for children helmet

Heat transfer film for children helmet

Hot stamping foil for children helmet

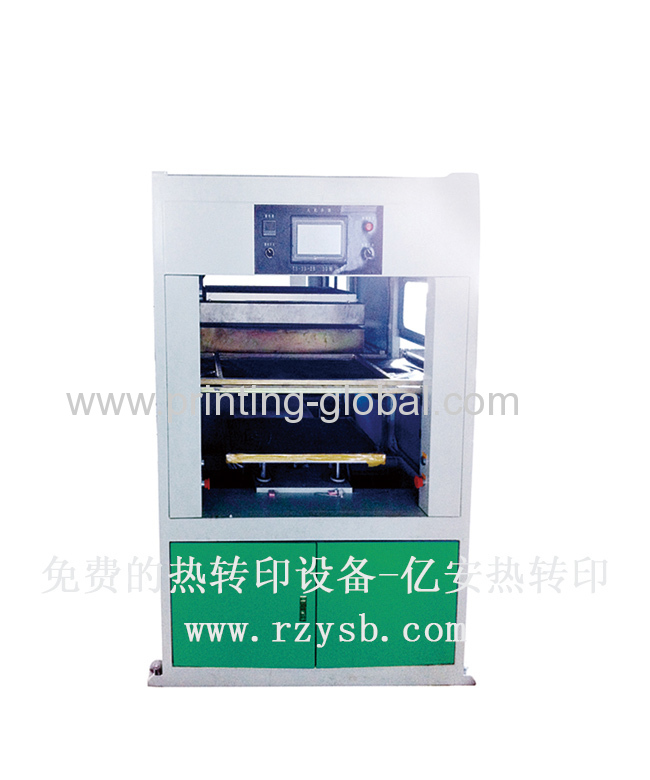

Machine can print on children helmet called 3D vacuum heat transfer printing machine

3Dvacuum heat transfer printing machine can also print on the following product:

About Aeon Printing Materials Co.,Ltd