13000ml Circuit Board Ultrasonic Cleaner

| Min. Order: | 50 PCS |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 350pcs/day |

| Place of Origin: | Guangdong |

Company Profile

| Location: | Shenzhen, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | GT-2013QTS |

|---|---|

| Means of Transport: | Ocean, Air |

| Certification: | CE |

| Use: | Home |

| Brand Name: | GT SONIC |

| Capacity: | 13L |

| Power: | 300W |

| Voltage: | AC220-240V,50HZ |

| Tank Material:: | Stainless Steel SUS304 |

| Tank size(mm): | 330×300×150 (L×W×H) |

| Ultrasonic Power:: | 300W |

| Heating Power:: | 400W |

| Certification:: | CE |

| Weight: :: | 11.8KG |

| Frequency:: | 40KHz |

| Production Capacity: | 350pcs/day |

| Packing: | Canton box |

| Delivery Date: | 2-5 days for sample order |

Product Description

GT-2013QTS Ultrasonic Cleaner

Factory:

Guangdong GT SONIC technology park, located in Meizhou, with its total area 120acres building, can assure our solid production ability. Based on advanced equipment, scientific technology and strict quality system, our product quality has been the ultrasonic industry leader.

Meeting Room:

Features:

● High-performance transducer systems

● LED-Display for temperature and timer

● Improved cleaning performance with sweep

● User-friendly and clear operating panel, splash water proof

● Cavitation-resistant stainless steel tank for a long service life

● Operator-controlled pause function allows product or sample inspection

● Convenient side-mounted solution drain valve opens rear-mounted drain

● Auto safety shut-off after 8 hours prevents unintended permanent operation

● Degas function for automatic degassing cycles, i.e.

● High-performance transducer systems

● LED-Display for temperature and timer

● Improved cleaning performance with sweep

● User-friendly and clear operating panel, splash water proof

● Cavitation-resistant stainless steel tank for a long service life

● Operator-controlled pause function allows product or sample inspection

● Convenient side-mounted solution drain valve opens rear-mounted drain

● Auto safety shut-off after 8 hours prevents unintended permanent operation

● Degas function for automatic degassing cycles, i.e.

Ultrasonic cleaning:

Application:

Ultrasonic cleaner is widely applied to different fields: dental instruments,lab instruments,hospital instruments,blind,PC bohardware,ard,chemical industry,circuit board,carburetor,printer head,and etc.

Ultrasonic cleaning uses cavitation bubbles induced by high frequency pressure (sound) waves to agitate a liquid. The agitation produces high forces on contaminants adhering to necklace,earings,bracelets, rings,eyeglass,lense,denture,badge and printer head. This action also penetrates blind holes, cracks, and recesses. The intention is to thoroughly remove all traces of contamination tightly adhering or embedded onto solid surfaces. Water or other solvents can be used, depending on the type of contamination and the workpiece. Ultrasonic cleaning can be used for a wide range of workpiece shapes, sizes and materials.Objects must not be allowed to rest on the bottom of the device during the cleaning process, because that will prevent cavitation from taking place.

Application:

Ultrasonic cleaner is widely applied to different fields: dental instruments,lab instruments,hospital instruments,blind,PC bohardware,ard,chemical industry,circuit board,carburetor,printer head,and etc.

Specifications:

Model | GT-2013QTS |

Voltage | AC100~120V, 60Hz AC220~240V, 50Hz |

Frequency | 40KHz |

Power | 300W |

Tank capacity | 13L |

Tank size(mm) | 330×300×150 (L×W×H) |

Overall size(mm) | 360×330×310 (L×W×H) |

Unit weight | 11.8KG |

Lid | Have |

Heating | Have |

Drainage | Have |

Cleaning basket | Optional |

Shipping Information:

Package size(mm) | 445×410×395 (L×W×H) |

Carton size (mm) | 460×425×410 (L×W×H) |

Qty/CTN | 1pcs |

20' container | 324pcs |

40' container | 673pcs |

Packing Information:

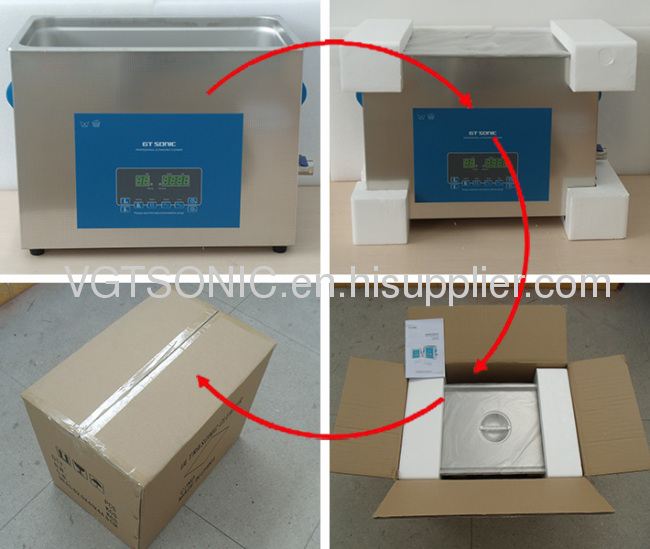

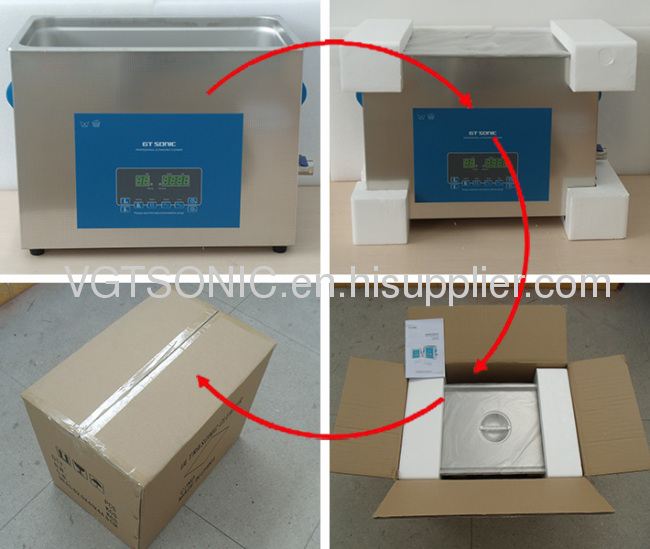

Our products perfectly enclosed in the package can protect it from various of physical damages, such as mechanical shock, vibration, electrostatic discharge, compression, temperature. We ship it with a large carton packaged 1pcs GT-2013QTS cleaner.There are four packaging steps. The picture below display the process detail.

Assembly Line:

It is depicted in the picture that our workers is assembling products. They all possess a team orientation, a commitment to quality, a respect for following processes and procedures, a systematic approach to task accomplishment and a strong task focus. In order to assure best quality, they concentrate on every detail, never tolerance the neglect of any faulty.

Factory:

Guangdong GT SONIC technology park, located in Meizhou, with its total area 120acres building, can assure our solid production ability. Based on advanced equipment, scientific technology and strict quality system, our product quality has been the ultrasonic industry leader.

R&D and Marketing Office:

Depending on our strong marketing team and excellent R&D team, GT has been developed into a big business. As we all know, excellent R&D engineer team is critical for the corporate, so we pay great attention to independent research and development. Strong R&D ability make GT friends assure that our products are reliable and best quality by holding advanced technology of ultrasonic. Now, most of developed products have got several patents and get customers, certain and appreciation.

Depending on our strong marketing team and excellent R&D team, GT has been developed into a big business. As we all know, excellent R&D engineer team is critical for the corporate, so we pay great attention to independent research and development. Strong R&D ability make GT friends assure that our products are reliable and best quality by holding advanced technology of ultrasonic. Now, most of developed products have got several patents and get customers, certain and appreciation.

Show room:

As we can see, GT SONIC, with edge ultrasonic technology advantage, has developed multiple of series to cater for vatiety of demands. Each series have varity of style and difference in size provide more choices for your choose.

As we can see, GT SONIC, with edge ultrasonic technology advantage, has developed multiple of series to cater for vatiety of demands. Each series have varity of style and difference in size provide more choices for your choose.

Meeting Room:

All of the specifications smart ultrasonic cleaner you can geted in there,we can according to your detail requirement to customize it .Any question pls don't hesitate to contact us.