The high technology edible oil refinery machine

5000.0~400000.0 USD

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T |

| Supply Ability: | 30 sets per months |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | YL-3 |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | Yongle |

| Production Capacity: | 30 sets per months |

| Packing: | according to customer's requirement |

| Delivery Date: | 30 days after deposit |

Product Description

1.Characteristics

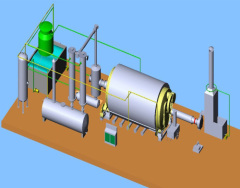

The oil refinery can be divided to three kinds: intermittent oil refinery machine, semi-continuous and continuous oil refinery machine. This equipment can produce high quality cooking oil or salad oil.

Light weight, save electricity , convenient use, this machine do not need special basis, either indoor or outdoor is OK, just need to make up power source, water, prepare coal,alkali, Pacid, active clay, edible salt and other consume materials.

2. Units devices

(1). Refining pot: used to P-acid de-gumming, alkali refining de-acid and water rinsing.

(2). De-color pot: used to remove off pigments, bleaching oils and grease de-hydrate.

(3). De-odor pot: used to remove off oils odor, foreign smells (stainless made)

(4). Heattransfer oil stove: supply each device production needing heat energy,

temperature reach above 280 ° C.

(5). Steam generator: produce the needing steam for de-odoring and distillation.

(5). Vacuum pump: supply needing vacuum for dehydrate, decolor, deodor.

Vacuum degree can reach above 755mmHg.

(6). Press filter: filter clay, filter out clear oil.

(7). Air compressor: blow dry bleached clay, blow empty the leftover oil in the press filter.

3.Main refining process:

(1).P-acid degumming operation:

Drawing the filtered or settled crude oil into the neutral pot, control oil temperature

40 ° C, liquid level cover the neutral pot volume about 80 %. Add into the neutral pot

P-acid with 85% concentration, 0.1-0.2% oil weight. Start up neutral pot, make main

shalf stirring at 60-70 r/min, finish de-gumming in 30 min.

(2)alkali de-acid operation

After finish de-gumming process, at once add into lye carrying alkali refining

de-acid, lye concentration 16 ° Be ′, super alkali is 0.1-0.3% oil weight, after finish

adding, continuous stirring 30min, when soap particles accumulated condensing,

should reduce stirring speed, 30r/min avoid emulsion.

After adding alkali, gradually rising temp to the end temp 65 ° C, see to that the rising

temp speed should control at 1 degree per minute, not too fast. Shut off neutral pot

drive part, the oil settled in the pot 6-8 hours, make oil separate from soap.

(3)water rinse operation

Adjust the neutral pot oil temp to about 85 ° C, add into hot water whose temp higher oiltemp 10-15° C, the water use amount each time is 10-15% oil weight. Start neutral pot

drive part, make the main shalf stirring washing at 30r/min, make the oil and water fully contact, stirring time 5-10 min. If oil/soap separate not ideal, the oil contains relative

high left soap, the first time washing, better to use thin salt water evenly spray into oil.

(4).de-coloring:

After dehydrate, inhale 3-5% oil weight active clay into the de-color pot to carry absorb

de-coloring. Decolor pot main axis stirring speed 60r/min, time 20 min, vacuum degree

750mmHg, is the whole absorb de-color craft process requirement. Shut off vacuum

valve, open vacuum break valve, stirring non-stop, reduce the oil tempdown to 70 ° C,

the de-color finished. Continuous stirring, open oil outlet valve, press the de-color oil

into the press filter, filter away waste clay, the last use air compressor blow clean and

dry.

(5).De-odor operation:

Open the vacuum valve, make the pot inside vacuum degree gradually reach above 750mmHg. Inhale the de-color oil after filter into the de-odor pot, see to that oil amount

should cover the pot volume 60% Control oil temp at 240 ° C - 260 ° C, use the direct

steam under 0.1 -0.3Mpa to distillate 3-4 hours. Shut off steam, shut off heat source,

when the oil temp cooling to below 80 ° C, shut off vacuum, release de-odor oil , the

de-odor process has finished.

Until now, the product oil after de-odor is high cooking oil, there are some factories

carrying again one time fine filtering after de-odor to increase the oil qulity.

The salad oil refining process is same to the high cooking oil refining proc ess, just has

a little higher requirements in each section, for example, during alkali refining, the superamount alkali a little much, when decoloring, the bleaching agent much, deodor time

properly longer, the temp relatively higher, add one fine filtering section.