Platinum Coated (Platinized) Titanium/Niobium Anode

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Trade Term: | FOB,CFR,CIF,DAT,FAS,DDP,DAP,CIP,CPT,FCA,EXW |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | As the client's anode shapes and size |

| Place of Origin: | Shaanxi |

Company Profile

| Location: | Xi'an, Shaanxi, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | TJP |

|---|---|

| Brand Name: | Taijin |

| Substrate: | Titanium,Niobium, SUS316,Tantalum, Molybdenum and Tungsten |

| Coating: | Pure platinum |

| Platinum coating per micron: | 21.45g/m2 per micron |

| Current efficiency: | >90% |

| Pt-layer thickness:: | 0.5-15 microns |

| Platinum coating method: | Electroplating, thermo decomposition and mechnical compound |

| Quality Test: | PT coating thickness, PT coating surface microimage,PT coating adhension test |

| Application: | Electroplating, Cathodic Protection, Water Treatment etc. |

| Platinum coating technology support: | Northwest Institute of Non-ferrous Metal Research |

| The 3rd party certificates: | SGS, BV,UKAS,QMS |

| Production Capacity: | As the client's anode shapes and size |

| Packing: | Inner package: soft papaer, Outer package: plswood case |

| Delivery Date: | As the client's order volume (min. 2 days) |

Product Description

Platinized Titanium,Niobium Anodes

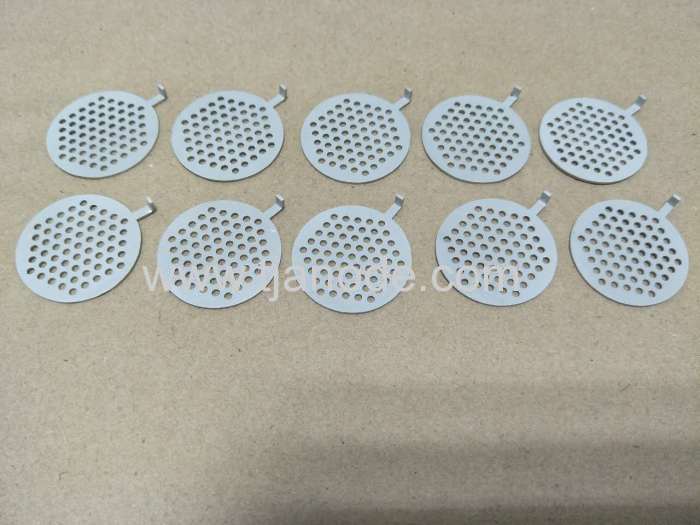

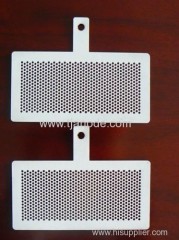

Platinum coated (Platinized) Titanium Anodes are highly conductive anodes used in electroplating, fuel cells, and other electrochemical applications. In general, platinum coated Titanium Anode is available in most volumes and can be fabricated in forms such as sheet, mesh, perforated plate, rod, or wire and so on.

Characteristic & highlights

1) Produce premium platinized titanium anodes in high purity and ultra high purity (up to 99.99999%) in compliance with applicable ASTM testing standards;

2) A series of grades are available including Mil Spec (military grade), ACS, Reagent and Technical Grade, Food, Agricultural and Pharmaceutical Grade, Optical Grade, USP and EP/BP (European Pharmacopoeia/British Pharmacopoeia).

We can also produce materials to custom specifications by request, in addition to custom compositions for commercial and research applications and new proprietary technologies. Typical and custom packaging is available, as is additional research, technical and safety (MSDS) data.

Welcome to contact us above for information on specifications, lead time and pricing.

1. Overview of Xi'an Taijin

1) Name: Xi'an Taijin Industrial Electrochemical Technology Co. Ltd.

2) Business model: State-governed, associated with Northwest Insititute For Nonferrous Metal Research

3)Establishment: Nov.20, 2000

4) Expertise and Experience: the earliest and biggest manufacturer of titanium electrodes in China market

5) Development & Patents: 38 professors and engineers, 54 patents in titanium electrodes field up to 2018

6) Quality Control and Assurance: independent laboratary and inspecting center, the complete and strict quality control system

7) Products and Services

To offer… Quality, Economy & On-time delivery of Titanium Electrodes,¨ Electro-chemical equipments, Engineering equipments under single platform to Marine, Chemical, Power, Water, Steel, Automobile, Electronics, Metal finishing & Aerospace Industries

By using… Precious metal oxides of Iridium, Ruthenium, Platinum, Palladium and exotic Metals like Titanium, Tantalum, Niobium, Zirconium, Nickel and their alloys to produce high premium and proving anodes for our clients.

To save... Power,reduce maintenance and assembly cost, resist corrosion,& avoid product contamination.

2. Application

1). Hard chrome plating

2). Precious and non- precious metal electroplating

3). Electrochlorination to anti-fouling and disinfection

4). Cathodic Protection

5). Electronics and semiconductor industry

6). Chemical process engineering

3. Quality Assurance

Certificates enclosed delivery

1). Platinum coating thickness test(SEM)

2). Platinum coating adhension test

3). Platinum coating surface visual test

4). Platinum coating surface microimages and coating composition (SEM, EDS)

5). Other test requested by customers.

4. Products