Titanium Electrodes Used in Industrial Wastewater Treatment

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Trade Term: | FOB,CFR,CIF,DAT,FAS,DAP,CIP,CPT,FCA,EXW |

| Payment Terms: | Paypal, L/C, T/T, WU |

| Supply Ability: | As the client's anode shapes and size |

| Place of Origin: | Shaanxi |

Company Profile

| Location: | Xi'an, Shaanxi, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | TJW |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | Taijin |

| Substrate: | Titanium ASTM B265 Gr1 |

| Coating: | Ruthenium & Iridum, Iridum & Tatalum, Platinum and Lead Dioxide |

| Size and construction: | Customized |

| Consumption rate: | Approximate 4 microgram/A.y |

| Application: | Electrochlorination to antifouling and disinfection, Clean scaling and reduce COD |

| Lead time: | Sufficient raw material storage to ensure the same delivery date as confirmed in the email |

| Quality control: | Strict quality management system directed by ISO 9000 |

| Long term partner: | Qingdao Suirui, Wuhan Xingda, Greece Enviromental Protection Engineering S.A. |

| Advantage 1: | Our company can supply the titanium anode and cathode, as well as a complete set of electrochlorination electrolyzer |

| Advantage 2: | Adapt to polarity reversal |

| Production Capacity: | As the client's anode shapes and size |

| Packing: | Inner package: soft papaer, Outer package: plswood case |

| Delivery Date: | As the client's order volume (min. 2 days) |

Product Description

Titanium Electrodes Used in Electrocatalytic Oxidation Technology for Industrial Wastewater Treatment

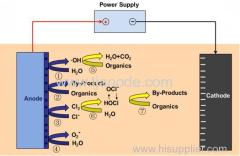

With the development of industry, organic wastewater discharge is increasing, especially high concentration organic wastewater in the fields of chemical and pharmaceutical emission. With high color and high toxicity, it contains a large number of biodegradation-resistant components. Electrocatalytic oxidation water treatment, which has been applied in hydrocarbon, alcohol, ether, phenol and other organic wastewater treatment, has many advantages: no need to add any chemicals; small size; small space occupied; and does not cause secondary pollution. The reaction of oxidation to remove organic matter mainly occurs on the anode surface (oxidation of the anode surface directly degrade the organic matter or form a strong oxidant active species called • OH on the anode surface to further oxidize and degrade the organic matter).

(1) The Composition of Refractory Industrial Wastewater

The composition of refractory industrial wastewater:

Halogen compounds, ether compounds, nitro, nitroso, azo compounds, tertiary amines and quaternary ammonium salts, organophosphorus, mercury, tin compounds, carbon heterocyclic compounds, oxygen-, nitrogen- and sulfur-heterocyclic compounds. (Toxic to organisms)

(2) Basic Principles of Electrocatalytic Oxidation Technology

The mechanism of the electrocatalytic oxidation process for organic wastewater treatment is to degrade the organic matter directly through the high potential and high catalytic activity of the anode surface or through reaction between the strong oxidants made by the anode surface (such as H2O2, • OH, ClO-, etc.) and toxic organic matter, and further degrade the toxic pollutants in wastewater.

(3) Advantages of Electrocatalytic Oxidation Technology

Anode material:

1. Oxygen evolution potential ≥1.70v, strong oxidation;

2. High current efficiency;

3. Insoluble anode, corrosion-resistant.

4. Anodic matrix reusable.

5. Low cost, long life span, cost-effective.

Wastewater treatment system:

1. Degrade stubborn or toxic contaminants;

2. Fully automatic operation, simple process;

3. Suitable for high salt load;

4. No sludge, no pollution transfer;

5. Degrade COD, decolorize;

6. Inactivate and sterilize;

(4) Engineering Examples

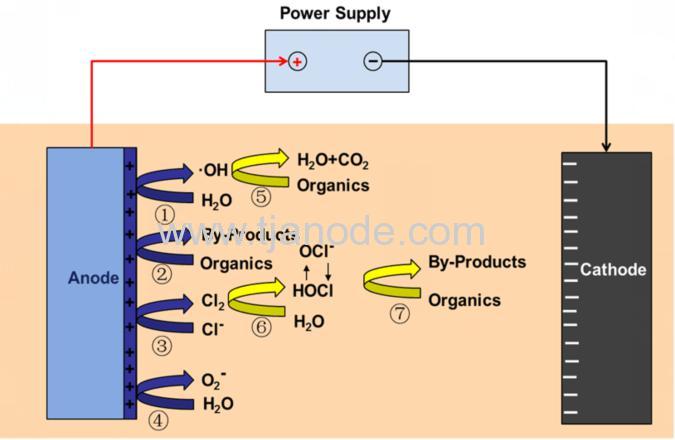

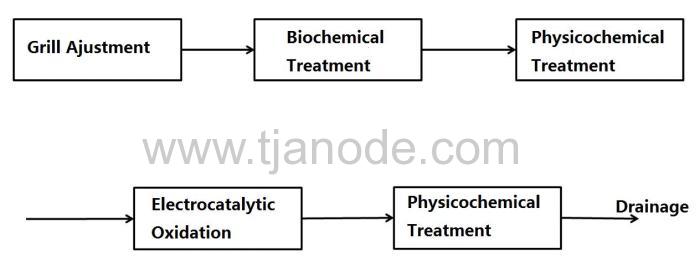

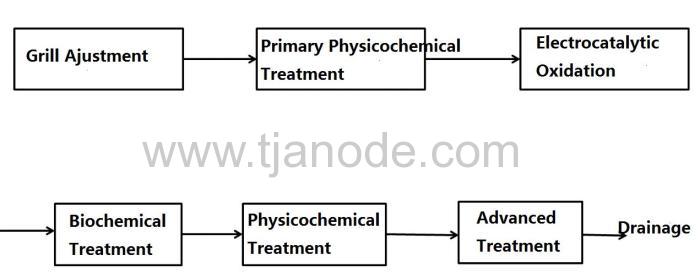

Ⅰ. A Corporate's Waste Water Electrocatalytic Oxidation Deep Treatment Process

The enterprise using biochemical treatment to process wastewater cannot meet the standards stably. After improving its wastewater treatment process by adding electrocatalytic oxidation technology, the water reached the standards stably.

Biochemical Effluent Water Quality Electrocatalytic Oxidation Advanced Treatment

TOC:57.2 TOC:19.3

COD:205.5 COD:54.4

SS:30 SS:0.5

TN:45.5 TN:41.5

Chroma:32 Chroma:4

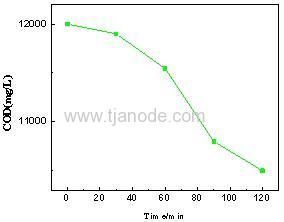

Ⅱ. A Chemical Plant Processes the Biodegradation-resistant Water

The waste water of the chemical plant was hard to be biodegraded, so biochemical treatment is not available. However, after using electrocatalytic oxidation method, the biodegradability of the wastewater was improved, then use biochemical treatment, the water reached the standards stably.

Original Water | After Electrooxidation Catalysis |

COD:12000ppm | COD:10500ppm |

BOD:1170ppm | BOD:4700ppm |

B/C Value:0.1(low biodegradability) | B/C Value:0.45(biochemical) |