Ru-Ir Titanium Electrodes for Electro-chlorination (Onsite Hypochlorinators) Systems

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Trade Term: | FOB,CFR,CIF,DAT,FAS,DAP,CIP,CPT,FCA,EXW,DDU |

| Payment Terms: | Paypal, L/C, T/T, WU |

| Supply Ability: | As the client's anode shapes and size |

| Place of Origin: | Shaanxi |

Company Profile

| Location: | Xi'an, Shaanxi, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | TJW |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | Taijin |

| Substrate: | Titanium ASTM B265 Gr1 |

| Coating: | Ruthenium & Iridum, Iridum & Tatalum, Platinum and Lead Dioxide |

| Size and construction: | Customized |

| Consumption rate: | Approximate 4 microgram/A.y |

| Application: | Electrochlorination to antifouling and disinfection, Clean scaling and reduce COD |

| Lead time: | Sufficient raw material storage to ensure the same delivery date as confirmed in the email |

| Quality control: | Strict quality management system directed by ISO 9000 |

| Long term partner: | Qingdao Suirui, Wuhan Xingda, Greece Enviromental Protection Engineering S.A. |

| Advantage 1: | Our company can supply the titanium anode and cathode, as well as a complete set of electrochlorination electrolyzer |

| Advantage 2: | Adapt to polarity reversal |

| Production Capacity: | As the client's anode shapes and size |

| Packing: | Inner package: soft papaer, Outer package: plswood case |

| Delivery Date: | As the client's order volume (min. 2 days) |

Product Description

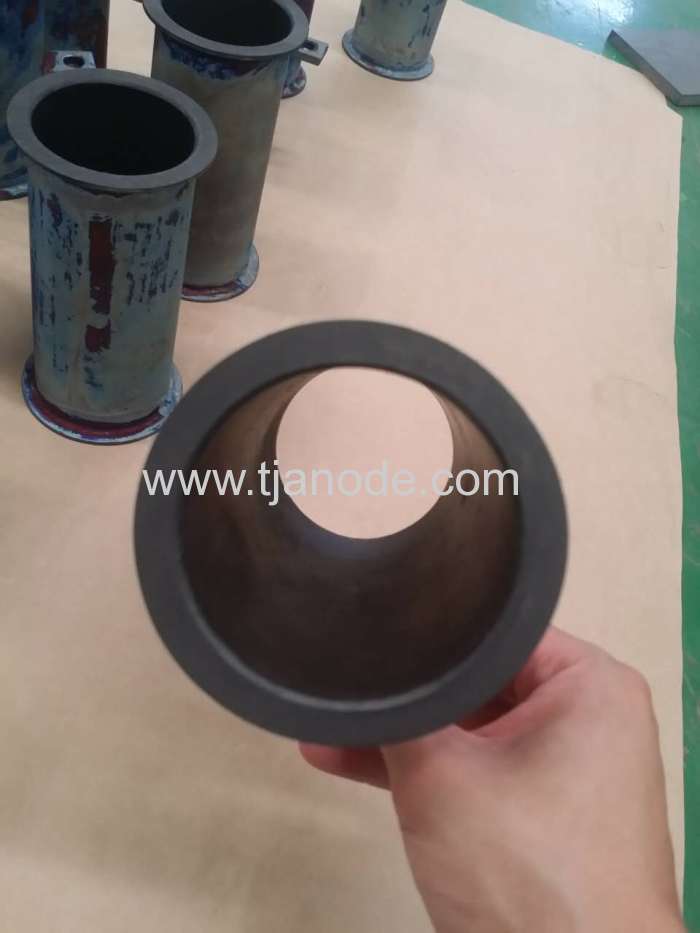

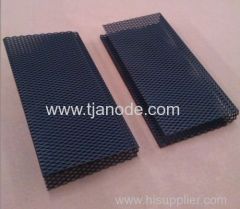

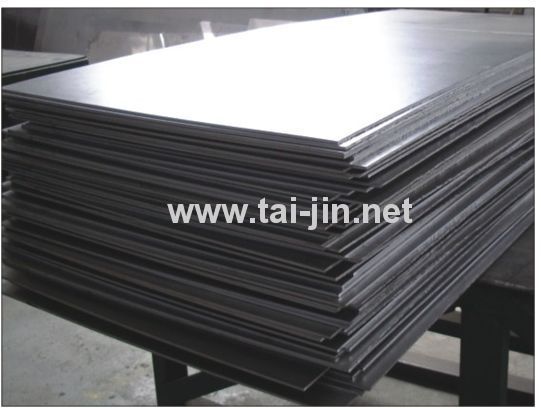

Mixed Metal Oxide(MMO) Coated Titanium Anodes & Cathodes for Electrochlorination to antifouling

1. Substrate and Coating:

1) Titanium ASTMB265 Grade 1-Expanded mesh, plates etc.

2) Coating Catalyst:Ru-Ir, Ir-Ta, Platinum and Lead Dioxide

2.Technical Parameters

a) Working life: 5 years under the working current 1000-1500A/m2

b) Accelerated life: ≥ 200 hours(Testing Standard: HG/T2471-2001)

c) Chlorine evolution potential: ≤1.2V(Testing Standard: HG/T2471-2001)

d) Polarizability : ≤40mV(Testing Standard: HG/T2471-2001)

3. Application(Cooling water,process water, ballast water, organic waste water)

1) Power Plant cooling water treatment

2) Ballast Water Treatment

3) Oil Rigs & Platforms process water

4) Oil Refineries Process water

5) Mining Industries Process water

6) Offshore Process water treatment

7) Petrochemical cooling water treatment

8) Boiler Feed Water Treatment System

9) Industries Using Fire Water Systems

10) HVAC Water Treatment System

11) Coolers Water Treatment System

5. Production Flow of MMO anode:

Raw material

--- Machining

---welding

--- Blasting

---Picking

---- coating

Manual brushing

Automatic coating

---Inspection---Package

Accelerated Life Test Coating Thickness Test

Packaging

5. Products