Titanium Anode Cathode for Electrochlorination to Antifouling

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Trade Term: | FOB,CFR,CIF,DAT,FAS,DAP,CIP,CPT,FCA,EXW,DDU |

| Payment Terms: | Paypal, L/C, T/T, WU |

| Supply Ability: | As the client's anode shapes and size |

| Place of Origin: | Shaanxi |

Company Profile

| Location: | Xi'an, Shaanxi, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | TJW |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | Taijin |

| Substrate: | Titanium ASTM B265 Gr1 |

| Coating: | Ruthenium & Iridum, Iridum & Tatalum, Platinum |

| Size and construction: | Customized |

| Consumption rate: | Approximate 4 microgram/A.y |

| Application: | Electrochlorination to antifouling and disinfection |

| Lead time: | Sufficient raw material storage to ensure the same delivery date as confirmed in the email |

| Quality control: | Strict quality management system directed by ISO 9000 |

| Long term partner: | Qingdao Suirui, Wuhan Xingda, Greece Enviromental Protection Engineering S.A. |

| Advantage 1: | Our company can supply the titanium anode and cathode, as well as a complete set of electrochlorination electrolyzer |

| Advantage 2: | Adapt to polarity reversal |

| Production Capacity: | As the client's anode shapes and size |

| Packing: | Inner package: soft papaer, Outer package: plswood case |

| Delivery Date: | As the client's order volume (min. 2 days) |

Product Description

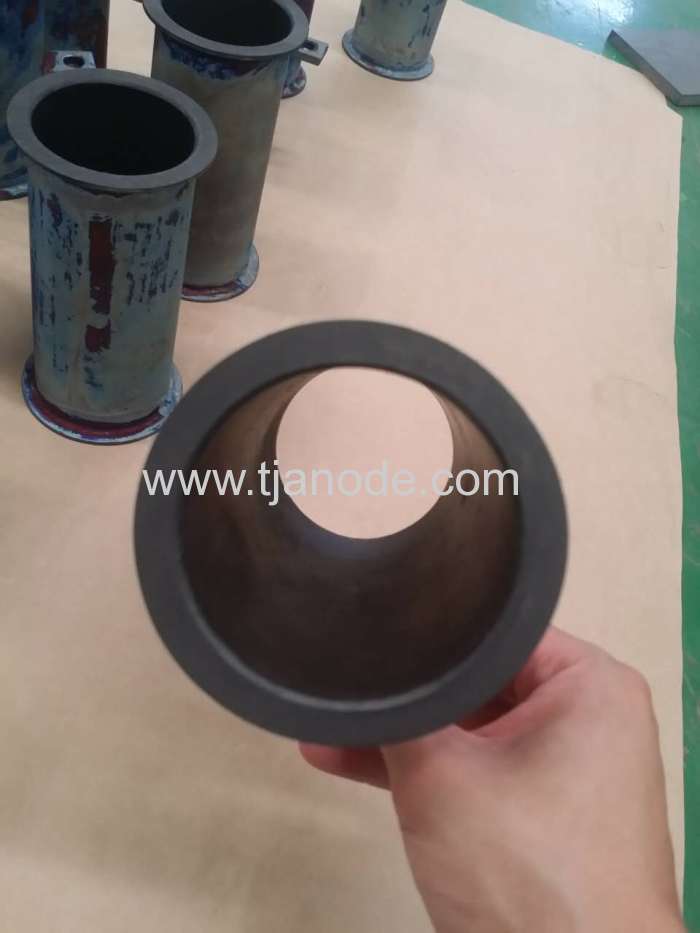

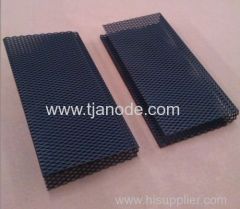

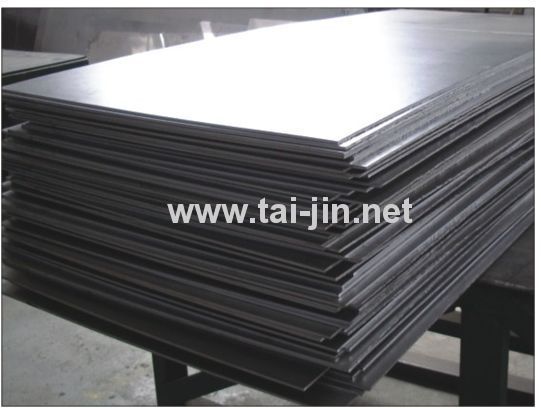

Mixed Metal Oxide(MMO) Coated Titanium Anodes & Cathodes for Electrochlorination to antifouling

1. Substrate:

1) Titanium ASTMB265 Grade 1-Expanded mesh, plates, sheet

Composition

C | max 0.08% |

N | max 0.03% |

H | max 0.015% |

Fe | max 0.20% |

O | max 0.18% |

Residual | max each 0.1% |

Residual | max total 0.4% |

Ti | balance |

2) Coating Catalyst:Mixed Metal Oxide & Platinum

2. Application Environment

a) Working life: 5 years under the working current 1000-1500A/m2

b) Accelerated life: ≥ 200 hours(Testing Standard: HG/T2471-2001)

c) Chlorine evolution potential: ≤1.2V(Testing Standard: HG/T2471-2001)

d) Polarizability : ≤40mV(Testing Standard: HG/T2471-2001)

3. Main Characteristics

1. Dimensionally stable.

2. MMO coating is insoluble.

3. Energy-saving and high efficient.

4. High current efficiency and catalytic.

5. Operating voltage is stable.

6. Long service life.

7. Light weight.

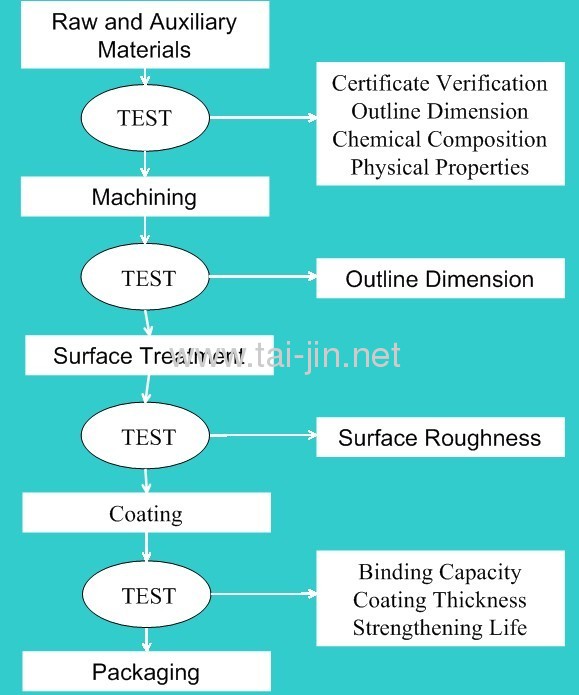

4. Production Flow of MMO anode:

Raw material

--- Machining

---welding

--- Blasting

---Picking

---- coating

Manual brushing

Automatic coating

---Inspection---Package

Accelerated Life Test Coating Thickness Test

Packaging

5. Quality Assurance

6. Products