Electrochlorination of Ru-Ir Titanium Anodes from China Manufacturer

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Trade Term: | FOB,CFR,CIF,DAT,FAS,DAP,CIP,CPT,FCA,EXW,DDU |

| Payment Terms: | Paypal, L/C, T/T, WU, Money Gram |

| Supply Ability: | As the shapes and speciation |

| Place of Origin: | Shaanxi |

Company Profile

| Location: | Xi'an, Shaanxi, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | TJW |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | Taijin |

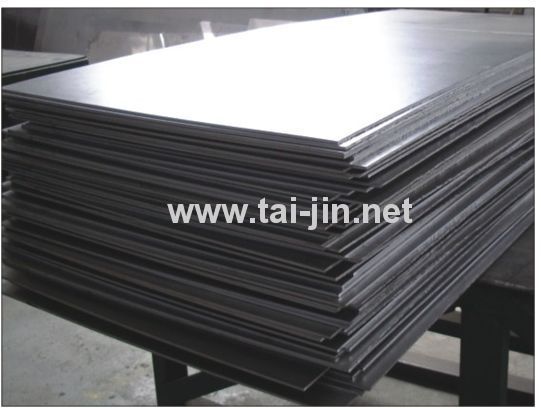

| Substrate: | Titanium ASTM B265 Gr1 |

| Coating: | Mixed Metal Oxide (MMO) |

| Specification and Shape: | As needed |

| Consumption rate: | Approximate 4 microgram/A.y |

| Advantage NO.1: | Manufacture of Titanium Anodes for 14 years |

| Advantage NO.2: | Our factory is located in the Titanium Materials Base of Northwest China |

| Advantage NO.3: | Passed ISO9001 Quality Management System |

| Advantage NO.4: | Technical Support from Head Company of Northwest Institute for Non-ferrous Metal Research |

| Advantage NO.5: | Supply the shipping freight primage |

| Production Capacity: | As the shapes and speciation |

| Packing: | Inner package: soft papaer, Outer package: plswood case |

| Delivery Date: | As the client's order volume (min. 2 days) |

Product Description

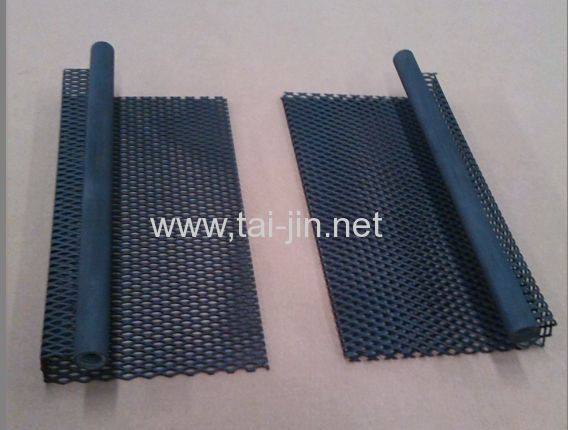

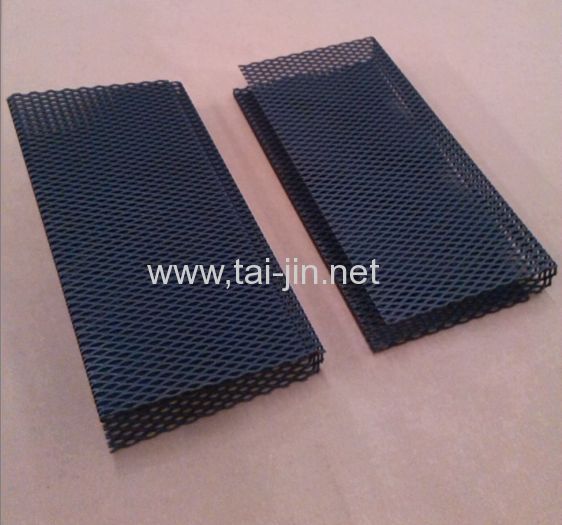

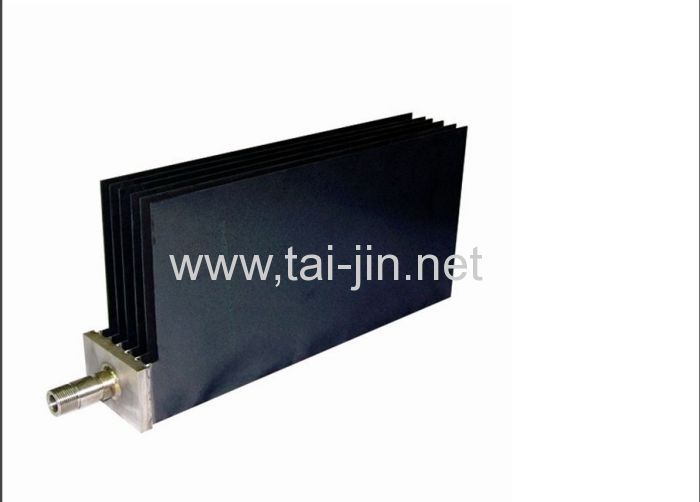

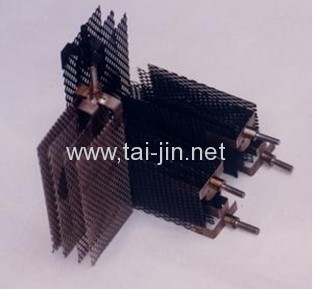

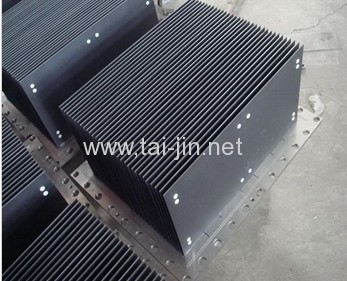

Titanium Anode for Electrolysing Sea and Salt Water

1. Substrate:

Pure titanium Gr1

1)Composition

C | max 0.08% |

N | max 0.03% |

H | max 0.015% |

Fe | max 0.20% |

O | max 0.18% |

Residual | max each 0.1% |

Residual | max total 0.4% |

Ti | balance |

2) Coating: Ruthenium-Iridium

2. Specification

titanium sheet 60*110*1.0mm /150*63*1.0mm

220*37*1.0mm / 185*50*2.0mm (according to your request)

3. Working life:

2 years,3 years,5 years

4. Parameters:

1) Current density < 2000A/M2

2) Working temperature: 40-60 centidegree

3) Chlorine-liberated potential

4) Working environment: water with salt or seawater

5) Reverse electrolysis frequency: 2 or 4 hours

5. Application:

1) For swimming pool disinfection

2) Ballast water treatment

3) Nuclear plants cooling water treatment

4) Treatment of hospital wastewater

5) Table-ware disinfection

6) Depolarization of dyeing wastewater treatment

7) Industrial cooling water circulation treatment

8) Electroplating waste water which containing cyanide

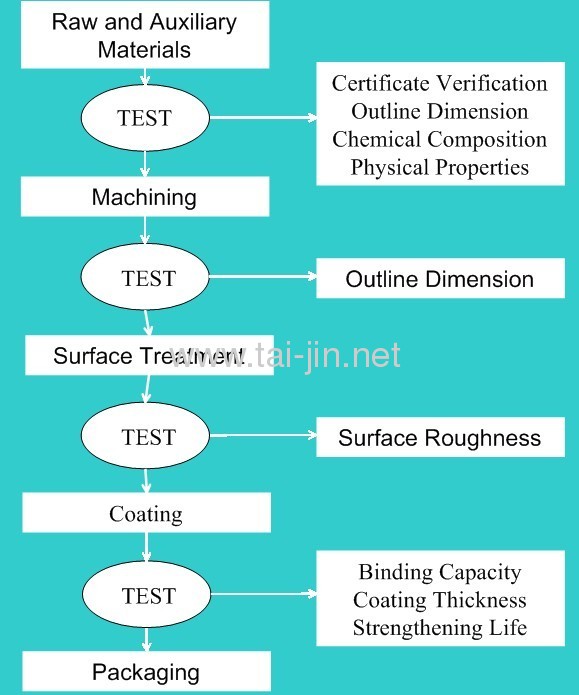

6. Quality Assurance

6. MMO Anode Processing Flow

Raw material

--- Shearing

--- Machining

---welding

--- Blasting

---Picking

---- coating

Manual brushing

Automatic coating

---Inspection---Package

Accelerated Life Test Coating Thickness Test

Packaging

7. The List of Products from Xi'an Taijin

1) Anode for Cathodic Protection

a) MMO Titanium Tube Anode/Platinized Titanium Tube Anode

b) MMO Titanium Disk Anode/ Platinized Titanium Disk Anode

c) MMO Titanium Rod Anode/ Platinized Titanium Rod Anode

d) MMO Titanium Sheet Anode/ Platinized Titanium Sheet Anode

e) MMO Wire Anode

f) MMO Titanium Mesh Ribbon Anode

g) MMO Titanium Ribbon Anode

h)Titanium Conductor Bar

i) MMO or Platinized Probe Anode

2) Titanium Anode for Hydrometallurgy

3) Titanium Anode for Electrolysing Copper Foil

4) Titanium Anode for Electrolysing Aluminum Foil

5) Titanium Anode for Sodium Hypochlorite and Seawater Electrolysis

6) Titanium Anode for Electrolysing Organic Synthesis

7) Noble Metal Compounds

8. Projects & Patents

a) Projects:

1.High Effective and Energy Saving Titanium Anode Used for Hydrometallurgy

2.The Development of Green and Novel Glass-to Metal Sealing Product

3.The Research and Production of High performance of Titanium Anode Composite Materials

4.The Research and Production of the Cathode Drum Used in Electrolyzing Copper Foil

b) Patents

1.A Kind of Brushing Device Used in Production of Titanium Ribbon and Titanium Mesh Ribbon

2.Dipping solution of the Coordination Compounds of Platinum and Prepare the Platinum Coating with it.

3.A Titanium Anode Device Used in a hydrometallurgical Electrodeposition of Metals

4.The Method of Removing Titanium Anode Coating

9. Products