MMO Titanium DSA Anode for Hydrometallurgy.

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Payment Terms: | L/C, T/T |

| Supply Ability: | 100 pieces 15 days |

| Place of Origin: | Shaanxi |

Company Profile

| Location: | Xi'an, Shaanxi, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | TJH |

|---|---|

| Means of Transport: | Ocean, Land |

| Brand Name: | TaiJin |

| Application: | Hydrometallurgy |

| Coating Catalyst: | Iro2 |

| Color: | Black |

| Country of origin: | China |

| Ti content: | 99.9% |

| Shape: | Different dimension is available |

| Powder or not: | Not powder |

| Substrate: | ASTM B265 Gr1 or Gr2 |

| Thickness of platinum:: | Max. Thickness 15micron |

| Quality:: | Confirm to system standard ISO9001:2008 |

| Production Capacity: | 100 pieces 15 days |

| Packing: | Plastic or paper as inside, carton or plywood case as outside |

| Delivery Date: | 2 days to 15 days depend on the quantity |

Product Description

MMO Titanium DSA Anode for Hydrometallurgy.

1.Specifications

1.IrO2 mixed MMO coated Titanium anode

Titanium ASTM B256 Grade1

2.Composition

C | max 0.08% |

N | max 0.03% |

H | max 0.015% |

Fe | max 0.20% |

O | max 0.18% |

Residual | max each 0.1% |

Residual | max total 0.4% |

Ti | balance |

3.Coating:

MixedMetal Oxide

electrolysis fresh water

high current efficiency & catalytic property

long life

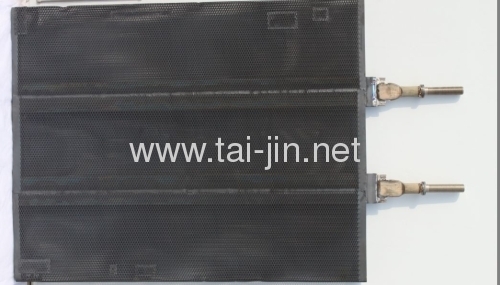

Titanium Anode for Making Oxygen | |

Material | Gr1 Titanium as substrate, Iridium-Tantalum oxide as coating |

Technology | Sand blasting,Acid washing and Brush Coating |

Coating Thickness | 8~12micron |

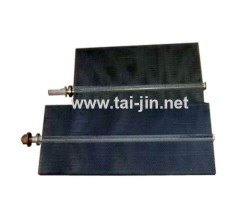

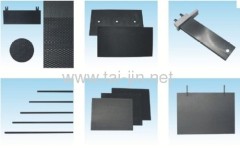

Dimension & Shape | Different dimension and shape is available, make according to custom design |

Working Parameter | l Current density<2000A/M2 l Temperature≤60°C l Max content of Fluoride ion is 200PPM |

Features | u High anti-corrosion property u Lasting working life u Keep the operating voltage stably u High current efficiency u High catalytic property |

Remarks |

|

Packing | Plastic or paper as inside, carton or plywood case as outside, or according to client's demand |

4.Quality Guarantee:

(1)Main quality indicators: substrate material, precious metal ratio, strengthen working life

(2)With advanced technology & equipment, abundant experiences and skilled workers, during the production of Titanium Anode, each process must be strictly supervised and tested, including the original material's quality, surface finish, coating quality, coating evenness degree, binding force between coating & substrate and so on. The only one aim is to provide the most excellent product, the lowest price and the best service for each client.

(3)Mill Test Certificate or Performance Test Report be provided before delivery to ensure the

quality if you need.

(4)The third party certificate such as GSG, RHOS etc are available

(5)Warmly welcome you send inquiry to us!

5.Production Flow of MMOanode:

Raw material --- Shearing ---Machining --- Blasting --- Picking----Automatic coating---Inspection---Package

6.Equipment

7.products