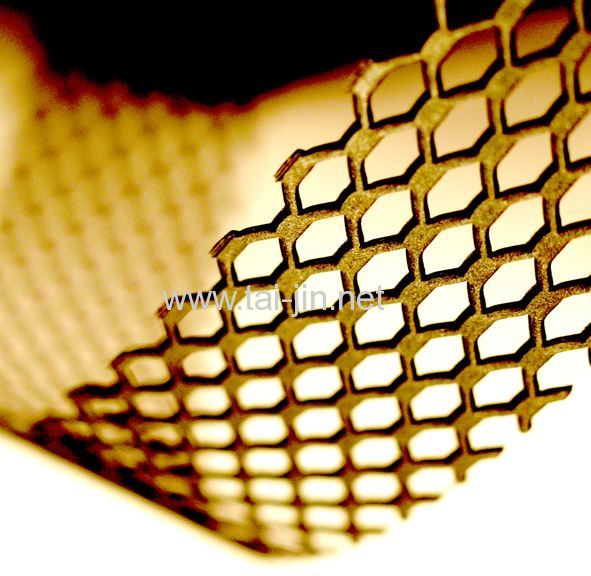

MMO Titanium Ribbon Mesh Anode for Cathodic Protection.

| Min. Order: | 1 Meter |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 10000 m per day |

| Place of Origin: | Shaanxi |

Company Profile

| Location: | Xi'an, Shaanxi, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | TJM |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | Taijin |

| Place of Origin: China: | Shaanxi,China (Mainland) |

| Ti content:: | 99.9% |

| FHWA limit:: | 110mA/m2(10mA/ft2) |

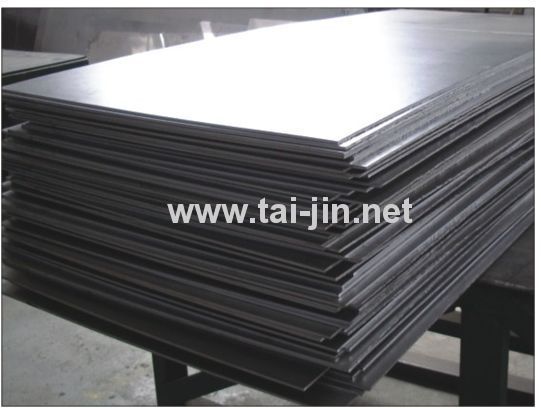

| Substrate:: | Gr1 ASTM B265 Titanium |

| Composition:: | Titanium ASTM B265 Gr1 or Gr2 |

| Expected life(NACE Standard TM02944-94):: | 100 years |

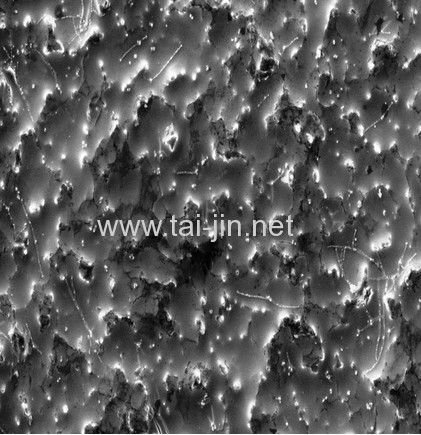

| Coating:: | Mixed Metal Oxide( Iridum base) |

| Coating uniformity:: | Greater than 90 percen |

| Anode features:: | Impressed current cathodic protection (ICCP) |

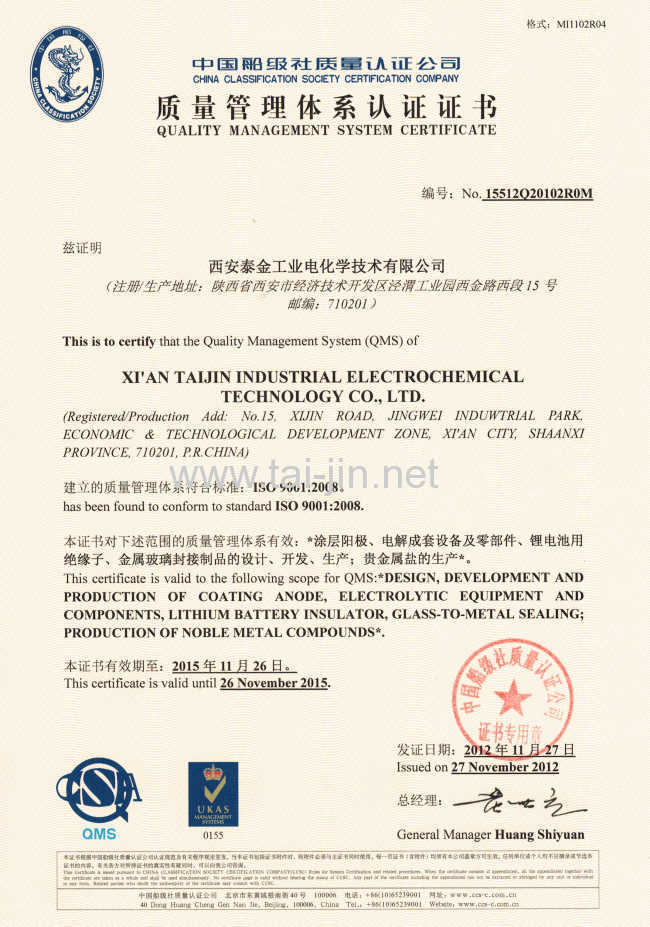

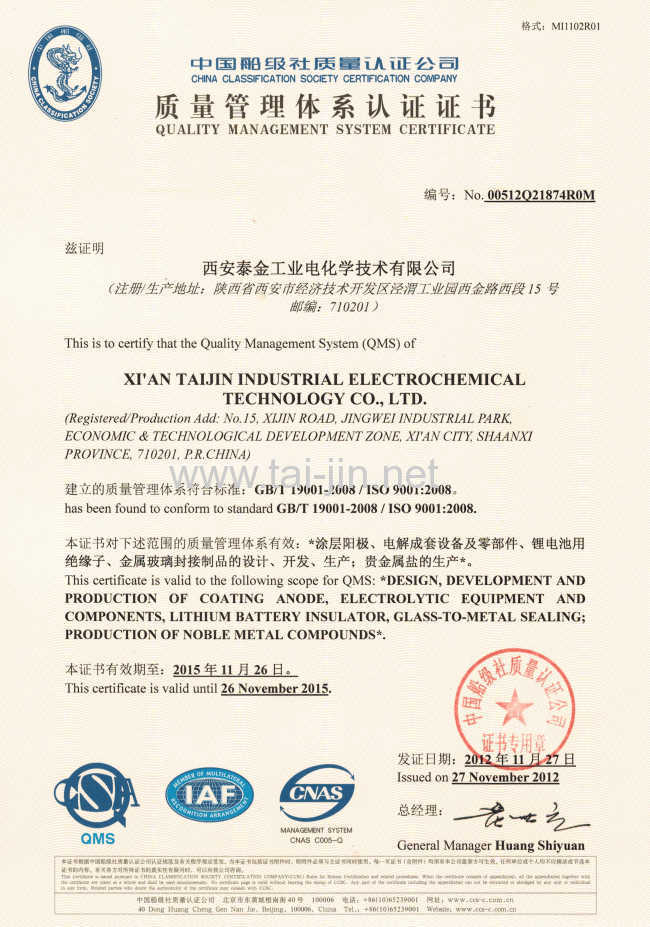

| Quality Control:: | Confirm to system standard ISO9001:2008 |

| Production Capacity: | 10000 m per day |

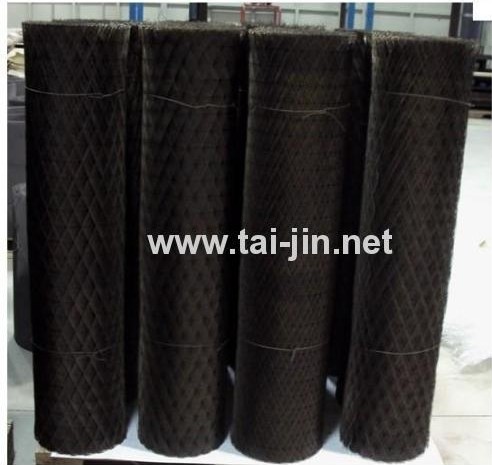

| Packing: | paper as inside, carton or plywood case as outside |

| Delivery Date: | 2 days to 15 days depend on the quantity |

Product Description

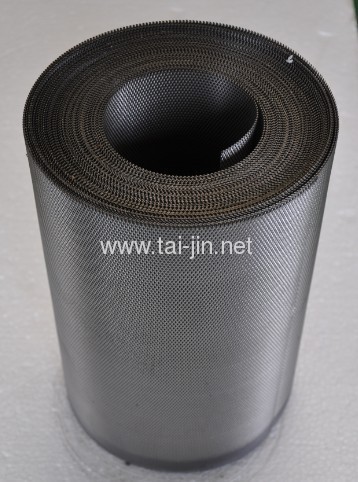

MMO Titanium Ribbon Mesh Anode for Cathodic Protection.

MMO Mesh Ribbon Anode

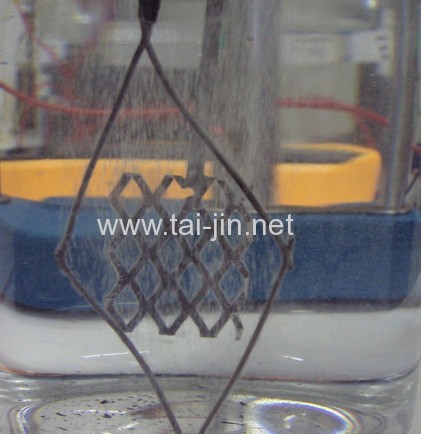

Mixed Metal Oxide (MMO) Mesh is a durable anode designed for ImpressedCurrent Cathodic Protection systems of steel structures and steel reinforcement concrete. The MMO coating, with industrially proven lifetime characteristics,ensures an even current distribution.

6"X10" great for all kinds of electrolysis can be used for:

Pool chlorination

Hydrogen fuel cell

Cholrate Cell

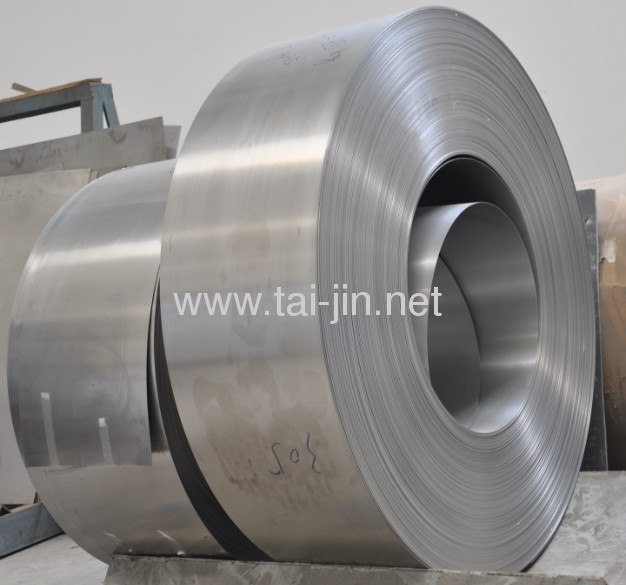

1. Substrate:

Pure titanium Gr1

1)Composition

| C | max 0.08% |

| N | max 0.03% |

| H | max 0.015% |

| Fe | max 0.20% |

| O | max 0.18% |

| Residual | max each 0.1% |

| Residual | max total 0.4% |

| Ti | balance |

2. Specification

Length x Width x Thickness

6.35*0.638mm lenth:152M/roll

12.7*0.9mm lenth:152M/roll

3. Application

Titanium anode basket are widly used in Electroplating industry, such as

(1)Precious metal plating(Ag, Au, Rh, Pd)

(2)Hard chrome plating(Cr6+)

(3)Base metal plating(Cu, Zn, Ni)

(4)Precious metal recovery, etc

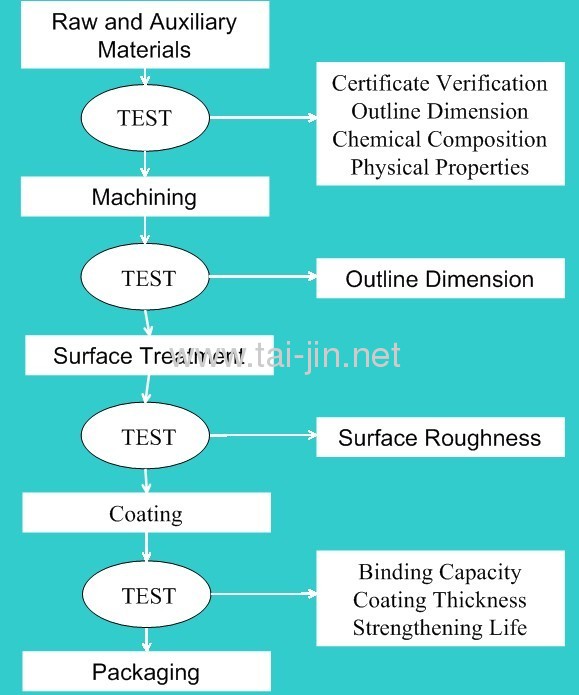

4. Production Flow of MMO anode:

Raw material

--- Shearing

--- Machining

---welding

--- Blasting

---Picking

---- coating

Manual brushing

Automatic coating

---Inspection---Package

Accelerated Life Test Coating Thickness Test

Packaging

5. Quality Assurance

6. Projects & Patents

a) Projects:

1.High Effective and Energy Saving Titanium Anode Used for Hydrometallurgy

2.The Development of Green and Novel Glass-to Metal Sealing Product

3.The Research and Production of High performance of Titanium Anode Composite Materials

4.The Research and Production of the Cathode Drum Used in Electrolyzing Copper Foil

b) Patents

1.A Kind of Brushing Device Used in Production of Titanium Ribbon and Titanium Mesh Ribbon

2.Dipping solution of the Coordination Compounds of Platinum and Prepare the Platinum Coating with it.

3.A Titanium Anode Device Used in a hydrometallurgical Electrodeposition of Metals

4.The Method of Removing Titanium Anode Coating

8. The List of Products from Xi'an Taijin

² Anodes Impressed Current for Cathodic Protection

Titanium Anodes

1)Mixed Metal Oxide Ti Wire & Piggy Back Wire Anode

2)Mixed Metal Oxide Ti Ribbon & Mesh Ribbon Anode

3)MMO/Platinized Ti Tubular & Anode string &Canister Anode

4)MMO/Platinized Ti Rod & Probe Anode

5)MMO/Platinized Ti Discrete Anode

6)MMO/Platinized Ti Disk & Sheet & Plate Anode

High Silicon Cast Iron Anode

1)HSCI Rod Anode

2)HSCI Tubular Anode

Cathodic Protection Materials

1)CP Wire and Cable

2)Anode Calcined Petroleum Coke Backfill

² Galvanic Anode

Magnesium anode

1)MG High Potential Anode

2)H-1 Alloy Mg Anode

3)Pre-packaged Mg Anode

4)Cast Mg Rod AZ-63 Alloy

5)Mg Extruded Rod /Ribbon Anode

Aluminum anode

1)Aluminum Cast Anode

2)Aluminum Extruded Rod Anode

Zinc Anode

1)Zinc Cast Anode

2)Zinc Ribbon anode

² Titanium Anodes Used in Other Field

1)Mixed Metal Oxide Titanium Anode for Hydrometallurgy

2)Mixed Metal Oxide Titanium Anode for Electrolysing Copper/ Aluminum Foil

3)Mixed Metal Oxide/Platinized Titanium Anode for Sodium Hypochlorite and Seawater Electrolysis

² Titanium Product

1)Titanium Clad Copper Metal Material

2)Titanium Art Products

3)Titanium Fasteners

Titanium Materi

7. Production Capacity

| Product | Product Capacity | Actual Amount Produced (Previous Year) |

Titanium anode for cathodic protection | 8000m2 | 5000m2 |

Titanium anode for hydrometallurgy | 15000m2 | 12000m2 |

| Titanium anode for copper foil | 5000m2 | 2000m2 |

| Titanium anode for aluminum foil | 5000m2 | 1000m2 |

Lithium battery seals | 60,000,000pcs | 40,000,000pcs |

Mil-spec connectors | 10,000pcs | 6,000pcs |

High temperature high pressure bulkheads | 5000pcs | 3000pcs |

Optical communication connectors | 100,000pcs | 50000pcs |

8. Company Development / Expansion Plans

| Company Development / Expansion Plans | ||

Item | Company Development Action | Timeframe |

1 | Developing new products and increasing twice in sales | Within 3 Years |

2 | To buy a new equipment (automatic coating production line) | Within 1 year |

3 | To get the certificate of Xi'an Enterprise Technology Center | Within 1 year |

4 | To pass the evaluation of Titanium electrodes engineering laboratory | |

9. Products:

Raw Materials

Half-finishedProducts

Finished Items

Packages