Platinum plated Titanium (Platinized Titanium) anode for electroplating

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 50 pieces per day |

| Place of Origin: | Shaanxi |

Company Profile

| Location: | Xi'an, Shaanxi, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | TJP |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | Taijin |

| Life time:: | 15years |

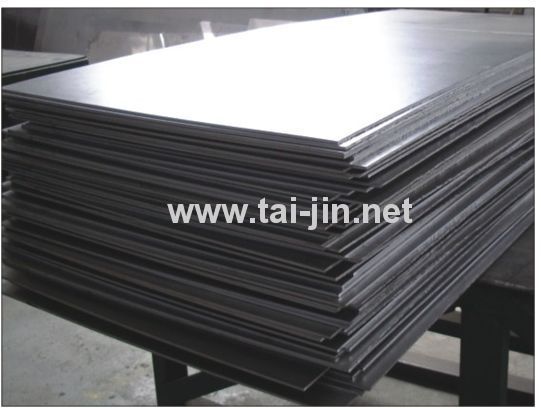

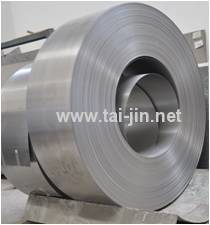

| Substrate:: | Titanium ASTM B338 Gr1 or Gr2 |

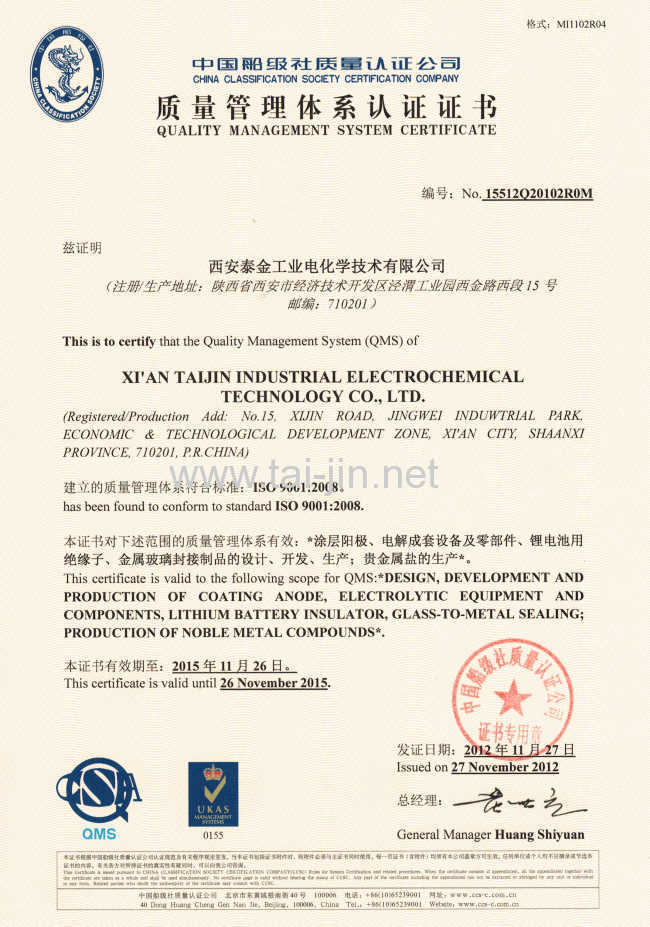

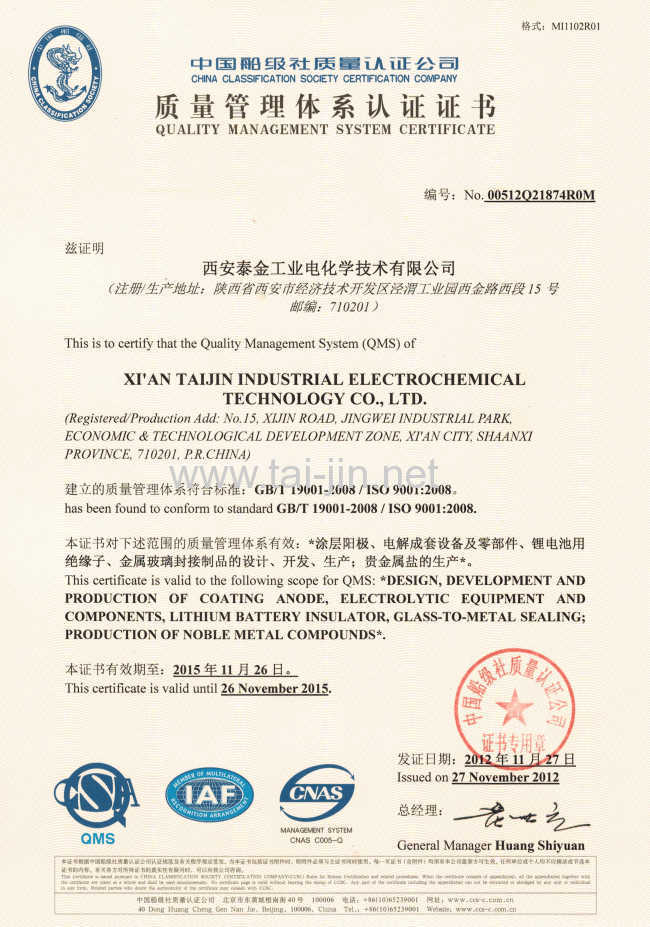

| Quality Control:: | Has been found to confirm to system standard ISO9001:2008 |

| Current output: | 800A/m2 |

| Technique:: | sanding blasting, acid washing, brush coating |

| Dimensions:: | As needed |

| Ti content:: | >99.9% Ti |

| Coating:: | Platinium |

| Power or not:: | Not power |

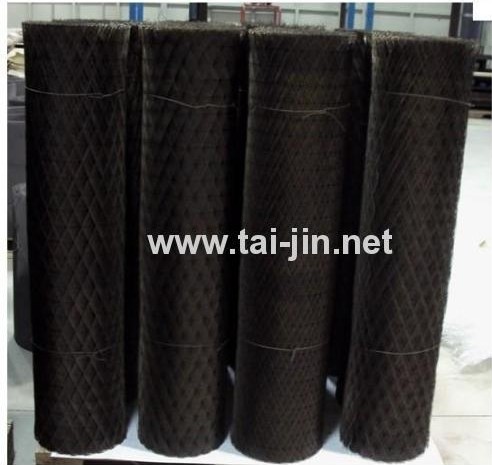

| Shape:: | Mesh, plate, tube, rod, wire |

| Production Capacity: | 50 pieces per day |

| Packing: | Plastic bags and form paper as inside,Wooden case as outside |

| Delivery Date: | 2 days to 15 days depend on the quantity |

Product Description

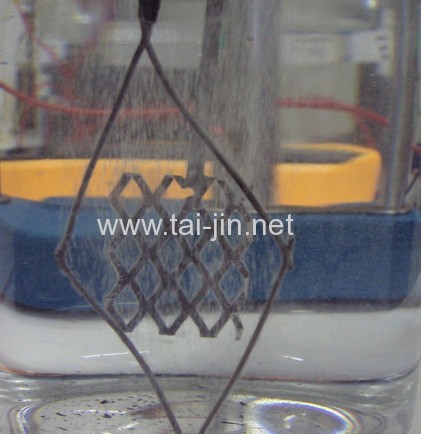

Titanium platinised anodes are designed & manufactured by Xi'an Taijin company.

Platinum plated Titanium (Platinized Titanium) anode

Platinised titanium anodes combine the excellent electrochemical characteristics of platinum with the good corrosion qualities of titanium. They are characterised by the following features and provide advantages over soluble anodes and lead anodes.

Platinum has three salient features as electrode materials :

1.Stability, corrosion resistance, and can be used for various medium

2.High over-potential during the process of oxygen evolution

3.Pt/Ti anode has be applied widely because of durability and good catalysis.

1. Substrate:

Pure titanium Gr1

1)Composition

| C | max 0.08% |

| N | max 0.03% |

| H | max 0.015% |

| Fe | max 0.20% |

| O | max 0.18% |

| Residual | max each 0.1% |

| Residual | max total 0.4% |

| Ti | balance |

2. Specification

Length x Width x Thickness

400x120x50mm,500x130x55mm,600x150x55mm,

700x175x60mm, 800x195x60mm,900x215x65mm,

1000x250x65mm,400x120x50mm,500x130x55mm,

600x150x55mm,700x175x60mm,800x195x60mm,

900x215x65mm,1000x250x65mm, etc.

3. Application

Titanium anode basket are widly used in Electroplating industry, such as

(1)Precious metal plating(Ag, Au, Rh, Pd)

(2)Hard chrome plating(Cr6+)

(3)Base metal plating(Cu, Zn, Ni)

(4)Precious metal recovery, etc

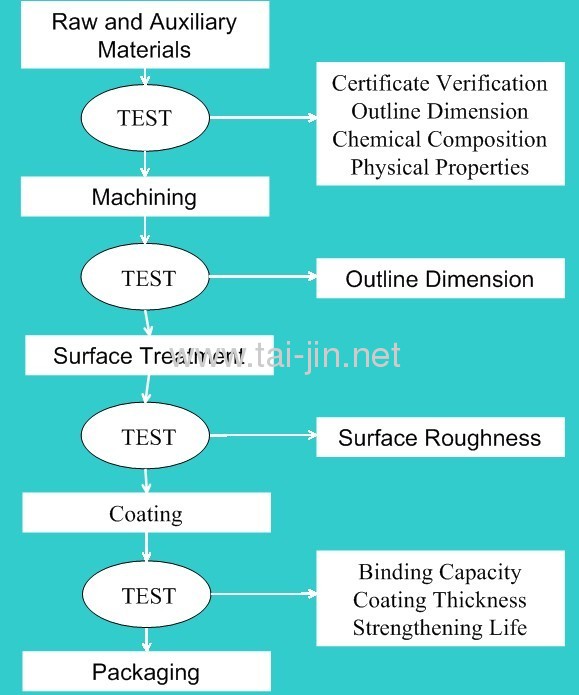

4. Production Flow of MMO anode:

Raw material

--- Shearing

--- Machining

---welding

--- Blasting

---Picking

---- coating

Manual brushing

Automatic coating

---Inspection---Package

Accelerated Life Test Coating Thickness Test

Packaging

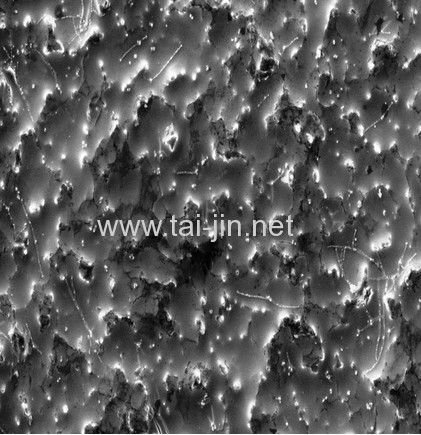

5. Quality Assurance

Quality Guarantee:

(1) Main quality indicators: titanium substrate, precious metal ratio, accelerated life, coating binding force to the titanium substrate/coating adhesion

(2) With advanced technology & equipment, abundant experiences and skilled workers,during the production of Titanium Anode, each process must be strictly supervised and tested, including the surface treatment of titanium material, coating quality, coating evenness, coating binding force to the titanium substrate and so on.

(3) We have own R&D, Production and Sales department, we always struggling to supply the product with the most excellent quality and the most favorable price and supply the most efficient service.

(4) Strict Pre-delivery inspection for each order, the original Mill Test Certificate available to attach to the delivery

(5) Warmly welcome you send inquiry to us.

6. Projects & Patents

a) Projects:

1.High Effective and Energy Saving Titanium Anode Used for Hydrometallurgy

2.The Development of Green and Novel Glass-to Metal Sealing Product

3.The Research and Production of High performance of Titanium Anode Composite Materials

4.The Research and Production of the Cathode Drum Used in Electrolyzing Copper Foil

b) Patents

1.A Kind of Brushing Device Used in Production of Titanium Ribbon and Titanium Mesh Ribbon

2.Dipping solution of the Coordination Compounds of Platinum and Prepare the Platinum Coating with it.

3.A Titanium Anode Device Used in a hydrometallurgical Electrodeposition of Metals

4.The Method of Removing Titanium Anode Coating

8. The List of Products from Xi'an Taijin

² Anodes Impressed Current for Cathodic Protection

Titanium Anodes

1)Mixed Metal Oxide Ti Wire & Piggy Back Wire Anode

2)Mixed Metal Oxide Ti Ribbon & Mesh Ribbon Anode

3)MMO/Platinized Ti Tubular & Anode string &Canister Anode

4)MMO/Platinized Ti Rod & Probe Anode

5)MMO/Platinized Ti Discrete Anode

6)MMO/Platinized Ti Disk & Sheet & Plate Anode

High Silicon Cast Iron Anode

1)HSCI Rod Anode

2)HSCI Tubular Anode

Cathodic Protection Materials

1)CP Wire and Cable

2)Anode Calcined Petroleum Coke Backfill

² Galvanic Anode

Magnesium anode

1)MG High Potential Anode

2)H-1 Alloy Mg Anode

3)Pre-packaged Mg Anode

4)Cast Mg Rod AZ-63 Alloy

5)Mg Extruded Rod /Ribbon Anode

Aluminum anode

1)Aluminum Cast Anode

2)Aluminum Extruded Rod Anode

Zinc Anode

1)Zinc Cast Anode

2)Zinc Ribbon anode

² Titanium Anodes Used in Other Field

1)Mixed Metal Oxide Titanium Anode for Hydrometallurgy

2)Mixed Metal Oxide Titanium Anode for Electrolysing Copper/ Aluminum Foil

3)Mixed Metal Oxide/Platinized Titanium Anode for Sodium Hypochlorite and Seawater Electrolysis

² Titanium Product

1)Titanium Clad Copper Metal Material

2)Titanium Art Products

3)Titanium Fasteners

Titanium Materi

7. Production Capacity

| Product | Product Capacity | Actual Amount Produced (Previous Year) |

Titanium anode for cathodic protection | 8000m2 | 5000m2 |

Titanium anode for hydrometallurgy | 15000m2 | 12000m2 |

| Titanium anode for copper foil | 5000m2 | 2000m2 |

| Titanium anode for aluminum foil | 5000m2 | 1000m2 |

Lithium battery seals | 60,000,000pcs | 40,000,000pcs |

Mil-spec connectors | 10,000pcs | 6,000pcs |

High temperature high pressure bulkheads | 5000pcs | 3000pcs |

Optical communication connectors | 100,000pcs | 50000pcs |

8. Company Development / Expansion Plans

| Company Development / Expansion Plans | ||

Item | Company Development Action | Timeframe |

1 | Developing new products and increasing twice in sales | Within 3 Years |

2 | To buy a new equipment (automatic coating production line) | Within 1 year |

3 | To get the certificate of Xi'an Enterprise Technology Center | Within 1 year |

4 | To pass the evaluation of Titanium electrodes engineering laboratory | |

9.package