insulated glass to metal

| Min. Order: | 100 Piece/Pieces |

|---|---|

| Payment Terms: | L/C, T/T |

| Supply Ability: | 100,000 per day |

| Place of Origin: | Shaanxi |

Company Profile

| Location: | Xi'an, Shaanxi, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | custom design |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | TaiJin |

| high quality: | glass to metal |

| hermetically seal: | good insulation |

| Long lifetime: | High corrosion and chemically resistant |

| Excellent hermeticity: | Superior temperature performance |

| reasonable price: | best service |

| Production Capacity: | 100,000 per day |

| Packing: | according to requirement |

| Delivery Date: | 15-30 days |

Product Description

Product Description

High temperature high pressure bulkheads are designed to function in the most severe of operating conditions and have been exposed to a combination of pressures and temperatures in excess of 25,000 PSI an 400°F(240°C). They are rugged enough to withstand the worst handling conditions in the field, whether they are on land or at sea.

We are also proficient in the business of customizing the design of high pressure bulkheads specifically to meet your project needs. Whether a minor modification, such as pin length or pin termination method, or a new, custom-made, design to meet even higher pressures and temperatures up to 30,000 PSI at 500ºF (260ºC), we have the experience to design, manufacture and test your product.

Product Description

High temperature high pressure glass-to-metal sealed electrical bulkheads are used in wire-line, MWD and LWD tools and completions by the Oil Field Services companies.

Technology Specifications

l Pressure and Temperature: 25,000 PSI @ 400ºF (204ºC)

l Insulation resistance: 500 MegOhms @ 500 VDC, Ambient temperature

l Dielectric withstanding voltage: 850 VAC / 1250 VDC

l Leak rate: 1×1×10-10Pa.m3/s.He

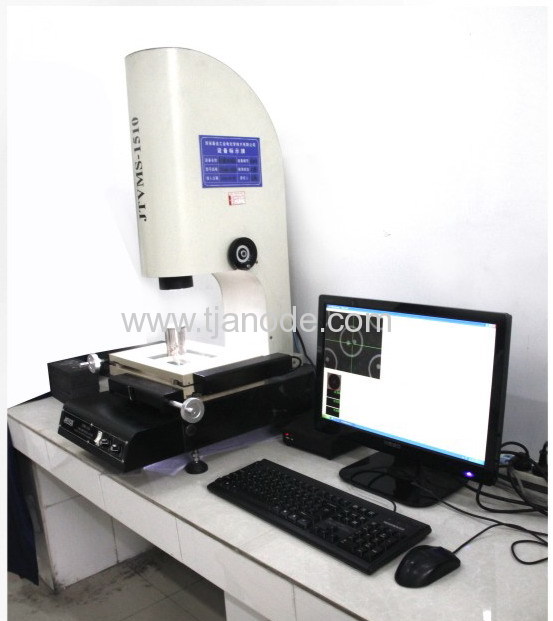

2.test equipment

3.quality certificate

Our total vertical integration includes:

1. Machining:

l Bodies, shells or metal housings: Inconel, Kovar and Nickel Alloys, Stainless Steel, Cold-Rolled Steel, Titanium

l Electrodes and contacts: Alloy 52, Inconel, Kovar, Molybdenum, Stainless Steel

2. Stamping

3. Precision grinding and lapping

4. Glass sintering furnaces

5. 5 Furnaces for glass-to-metal sealing

6. Innovative electroplating technology, including:

l Nickel (3 types)/ Tin, Tin-lead, Hot Solder Dip, Electropolishing of stainless steel

l Complete chemical analysis capability

7. Inspection / Testing

l Statistical Process Control/Optical comparators

l Humidity testing

l Temperature Cycling

l Optical Measuring Machines

l Hermeticity validation to 1 x 10-11 cc/sec of helium at 1 atmosphere differential pressure

l Insulation resistance to 10 gigaohms at 500 VDC

l Salt spray