Iridium and Tantalum oxide Titanium Anode for Copper Foil Electrolysis

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Payment Terms: | L/C, D/P, T/T, WU |

| Supply Ability: | 500 pieces 15 days |

| Place of Origin: | Shaanxi |

Company Profile

| Location: | Xi'an, Shaanxi, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | TJP |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | TaiJin |

| Application: | copper foil |

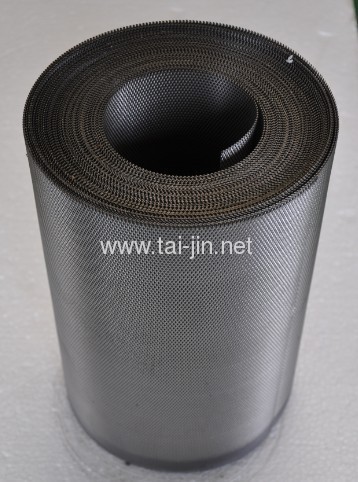

| Coating Catalyst: | Ir-Ta |

| Color: | Black |

| Country of origin: | China |

| Ti content: | 99.9% |

| Shape: | Different dimension is available |

| Powder or not: | Not powder |

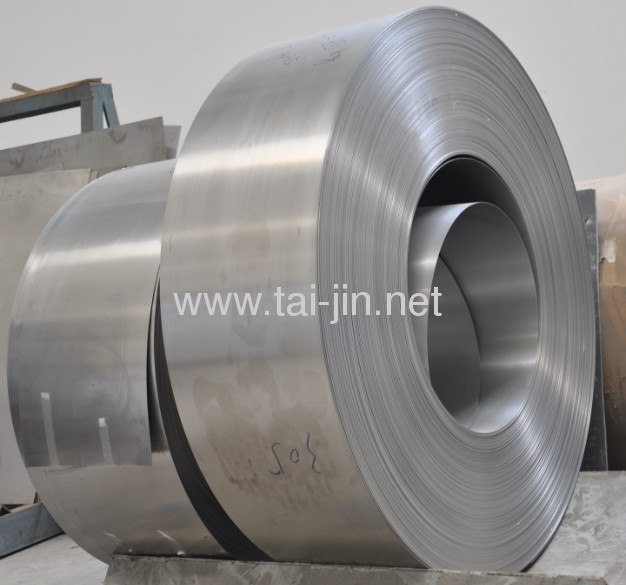

| Substrate: | ASTM B265 Gr1 or Gr2 |

| Quality control: | Confirm to system standard ISO9001:2008 |

| Technology: | Sand blasting, Acid washing and Brush Coating |

| Production Capacity: | 500 pieces 15 days |

| Packing: | Plastic or paper as inside, carton or plywood case as outside |

| Delivery Date: | 2 days to 15 days depend on the quantity |

Product Description

Iridium and Tantalum oxide Titanium Anode for Copper Foil Electrolysis

Material | Gr1 Titanium as substrate, mixed Iridium-Tantalum oxide as coating |

Technology | Sand blasting, Acid washing and Brush Coating |

Dimension & Shape | Different dimension and shape available, make according to custom design/design |

Applications |

|

Main Features | u High anti-corrosion property u Lasting working life u Low chlorine evolution voltage u Keep the operating voltage stably u High current efficiency u High catalytic property |

Remarks | v Titanium anode also called MMO anode,DSA & Insoluble anode v Cathode also be provided |

*Quality Guarantee:

(1)Main quality indicators: titanium substrate, precious metal ratio, accelerated life, coating binding force to the titanium substrate/coating adhesion

(2)With advanced technology & equipment, abundant experiences and skilled workers,during the production of Titanium Anode, each process must be strictly supervised and tested, including the surface treatment of titanium material, coating quality, coating evenness, coating binding force to the titanium substrate and so on.

(3)We have own R&D, Production and Sales department, we always struggling to supply the product with the most excellent quality and the most favorable price and supply the most efficient service.

(4)Strict Pre-delivery inspection for each order, the original Mill Test Certificate available to attach to the delivery

(5)Warmly welcome you send inquiry to us.

* Projects & Patents

a) Projects:

1.High Effective and Energy Saving Titanium Anode Used for Hydrometallurgy

2.The Development of Green and Novel Glass-to Metal Sealing Product

3.The Research and Production of High performance of Titanium Anode Composite Materials

4.The Research and Production of the Cathode Drum Used in Electrolyzing Copper Foil

b) Patents

1.A Kind of Brushing Device Used in Production of Titanium Ribbon and Titanium Mesh Ribbon

2.Dipping solution of the Coordination Compounds of Platinum and Prepare the Platinum Coating with it.

3.A Titanium Anode Device Used in a hydrometallurgical Electrodeposition of Metals

4.The Method of Removing Titanium Anode Coating

* The List of Products from Xi'an Taijin

1) Anode for Cathodic Protection

a) MMO Titanium Tube Anode/Platinized Titanium Tube Anode

b) MMO Titanium Disk Anode/ Platinized Titanium Disk Anode

c) MMO Titanium Rod Anode/ Platinized Titanium Rod Anode

d) MMO Titanium Sheet Anode/ Platinized Titanium Sheet Anode

e) MMO Wire Anode

f) MMO Titanium Mesh Ribbon Anode

g) MMO Titanium Ribbon Anode

h)Titanium Conductor Bar

i) MMO or Platinized Probe Anode

2) Titanium Anode for Hydrometallurgy

3) Titanium Anode for Electrolysing Copper Foil

4) Titanium Anode for Electrolysing Aluminum Foil

5) Titanium Anode for Sodium Hypochlorite and Seawater Electrolysis

6) Titanium Anode for Electrolysing Organic Synthesis

7) Noble Metal Compounds

* Production Capacity

Product | Product Capacity | Actual Amount Produced (Previous Year) |

Titanium anode for cathodic protection | 8000m2 | 5000m2 |

Titanium anode for hydrometallurgy | 15000m2 | 12000m2 |

Titanium anode for copper foil | 5000m2 | 2000m2 |

Titanium anode for aluminum foil | 5000m2 | 1000m2 |

Lithium battery seals | 60,000,000pcs | 40,000,000pcs |

Mil-spec connectors | 10,000pcs | 6,000pcs |

High temperature high pressure bulkheads | 5000pcs | 3000pcs |

Optical communication connectors | 100,000pcs | 50000pcs |

*Company Development / Expansion Plans

Company Development / Expansion Plans | ||

Item | Company Development Action | Timeframe |

1 | Developing new products and increasing twice in sales | Within 3 Years |

2 | To buy a new equipment (automatic coating production line) | Within 1 year |

3 | To get the certificate of Xi'an Enterprise Technology Center | Within 1 year |

4 | To pass the evaluation of Titanium electrodes engineering laboratory | |

*Products:

Raw Materials

Half-finishedProducts

Finished Items

Packages