Titanium MMO Ribbon Electrodes

| Min. Order: | 1 Meter |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 3000 meters per day |

| Place of Origin: | Shaanxi |

Company Profile

| Location: | Xi'an, Shaanxi, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | TJR |

|---|---|

| Means of Transport: | Ocean, Land |

| Brand Name: | Taijin |

| Substrate: | Titanium ASTM B265 Gr1 or Gr 2 |

| Curent output: | Min. 17mA/m |

| Application enviroment: | Soil |

| Catalyst: | Mixed metal oxide |

| Working life: | 50 years |

| Stock of half-finished product: | 30000m-50000m |

| Stock of finished product: | 10000m |

| Quality control: | ISO9001:2008 |

| Country of origin: | China |

| Please input attribute name: | Please input the attribute value |

| Production Capacity: | 3000 meters per day |

| Packing: | Inner package: soft papaer, Outer package: plswood case |

| Delivery Date: | As the client's order volume (min. 2 days) |

Product Description

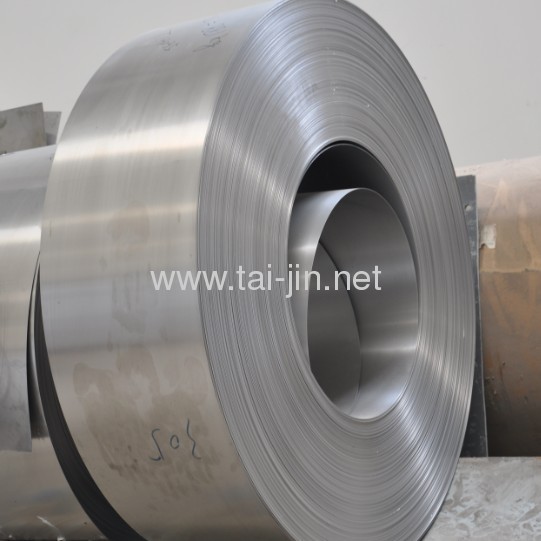

Titanium MMO Ribbon Anode

1. Substrate:

Titanium ASTM B265 Grade 1 or Grade 2

Chemical Composition

C | max 0.08% |

N | max 0.03% |

H | max 0.015% |

Fe | max 0.20% |

O | max 0.18% |

Residual | max each 0.1% |

Residual | max total 0.4% |

Ti | balance |

2. Parameters

| Coating | IrO2+Ta2O5 | |

| Thickness | 0.635mm | 0.9mm |

| Width | 6.35mm | 12.7mm |

| Length | 152m per coil | 152m per coil |

| Net Weight | 2.8kg per roll | 7.8kg per roll |

| Working life | 50 years | 50 years |

| Current output | Min.17ma/m | Min.34ma/m |

3. Production Flow of MMO anode:

Raw material --- Shearing --- Picking ----Automatic coating ---Inspection---Package

4. Application:

Application:

a) In fine sandy loam

b) Release Cl2 or O2, or both releases Cl2 and O2 environmen

c) Typically used for cathodic protection of the ground tank bottom andreinforced concrete structures

d) Internal protection of storage tanks, condensers, pipes, pipelines, heat exchangers and boilers.

e) External protection of pipelines, ship hulls, platforms and other offshore constructions, piers,dams and cooling water inlet parts of power stations.

f) Tank bottoms

5. Equipment

6. Products