New Design Multifunction Punching and Comb Wire Spiral Coil Binding Machine(SUPER4&1)

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Payment Terms: | D/A, T/T, WU |

| Supply Ability: | 100pc/month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Hangzhou, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Binding Machine |

Product Detail

| Model No.: | SUPER 4IN1 |

|---|---|

| Means of Transport: | Ocean, Land |

| Brand Name: | SUPU |

| Binding thickness for comb binding: | 500sheets |

| Binding thickness for wire binding: | 380sheets |

| Binding thickness for coil: | 180sheets |

| Material: | All aluminum |

| Machine weight: | 100kg |

| Punch margin adjustable: | 2mm~6mm |

| Continual punch pages: | 2500 pages/minute ~ 3000 pages/minute |

| Power supply: | AC220V-240V 50Hz |

| Electromotor power: | 200W |

| Machine dimension: | 612mmx510mmx394mm |

| Production Capacity: | 100pc/month |

| Packing: | 1pc/wooden case |

| Delivery Date: | 25days |

Product Description

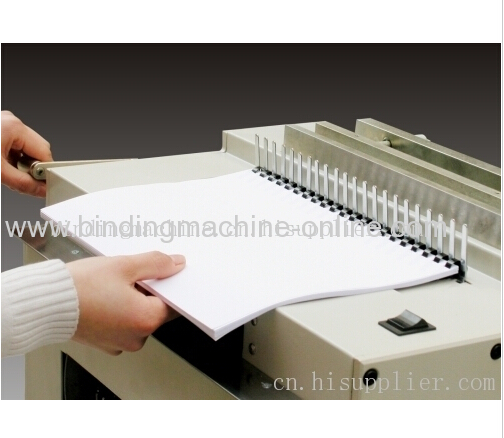

Multifunctional punching and comb wire spiral binding machine SUPER 4IN1

PRODUCT DESCRIPTION

SUPER4&1 binding machine is a type of multifunctional punch machine with many advantages,

such as international patent design, reasonable configuration, stable performance, human in operation.

This type of machine has spacious outward appearance, big operation panel, and high-grade electromotor of retarder. Punching is controlled by electrical foot pedal. The electric motor stop

automatically after each punching which is safe, stable and low noise.

It is very convenient to change punching die by revolving die-changing handle and suitable for many types of holes. One machine with four punching dies which are 2:1,3:1,4:1

and comb .Also with double wire binding ,Comb binding and Spiral binding .So this is All together in One machine .

It surely will be your good assistant of work.

Item | Plastic comb | Double wire (2:1&3:1) | Spiral(Oval) (4:1) | |

Punching thickness of sheets | 25sheets(70 g) 20sheets(80g) | 25sheets(70 g) 20sheets(80g) | 25sheets(70 g) | |

Punching thickness of PVC Cover | 4 sheets(0.2mm) | 4 sheets(0.2mm) | 4 sheets(0.2mm) | |

Punching thickness of 230g Cover | 4sheets | 4sheets | 4sheets | |

Binding thickness | 4.5mm~51mm | 15.9mm~32mm(2:1) 4.8mm~14.3mm(3:1) | 4.5mm~50mm | |

Punch width | 297mm | |||

Die disengagement pin | Full(21 pins) | Full 2:1(23 pins) 3:1(34 pins) | Full (47 pins) | |

Punch margin adjustable | 2mm~6mm | |||

Continual punch pages | 2500 pages/minute ~ 3000 pages/minute | |||

Power supply | AC220V-240V 50Hz | |||

Electromotor power | 200W | |||

Machine dimension | 612mmx510mmx394mm | |||

Machine wight | 90KG | |||

INSTALLSTION AND ADJUSTMENT

1.Place the machine on workbench after opening the case, make sure it is steady on four feet.

Connect the power socket and foot pedal joint

2.Assemble comb binding handle, wire binding handle to make it is nearly 90°to the top of base and then assemble the lock handle and die-changing handle and make the lock handle stay at the lock up position .(see drawing 4)

METHOD AND PROCEDURE TO PUNCH

1.Following above method to choose right punching die

2.Accroding to the paper's size, adjust side margin and paper fixer to suitable position.

3. Turn on power and try to put little paper and then treat the foot pedal to do a testing(See picture) .

OPERATION INSTRUCTIONS AND USE FOR DOUBLE WIRE(2:1,3:1)

1.Choose right punching die for double wire (2:1 or 3:1). According to paper's size choose paper

fixer and side margin controller. Insert paper then treat foot pedal to finishing punching.

2.Adjust two adjustable knobs according to size of wire

3.Closing the wire by using the closing handle .

OPERATION INSTRUCTIONS AND USAGE FOR SPIRAL

1.Choose the right punching die for Spiral. According to paper's size choose paper fixer and side margin controller. Insert paper then treat foot pedal to finishing punching.

2.Inserter the coil to the punched sheets by handle in the first circles then press roller button to make roller run then lean the coil against the roller to make it inserting automatically .

3.Cut and crimp the coil with plier attached with machine ,completing the binding(see pictures)

OPERATION INSTRUCTIONS AND USAGE FOR COMB

1,Choose the right punching die for comb. According to paper's size choose paper fixer and side margin controller.

Insert paper, then treat foot pedal to finishing punching.

2,Place plastic ring in back of comb with opening upward, pull down the binding handle clockwise to open the comb .

3,Place the punched sheets into the comb then push the binding handle upward counterclockwise to finish binding .

4,If sheets need to be increased or decreased follow step 2.After it follow step 3 to binding.

WORKSHOP

EXHIBITION

CERTIFACTION