single side pcb design for led light for traffic sign

57.0~200.0 USD

| Min. Order: | 1 Square Meter |

|---|---|

| Trade Term: | FOB |

| Supply Ability: | 1000square meter/per day |

| Place of Origin: | Guangdong |

Company Profile

| Location: | Shenzhen, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | PCB |

Product Detail

| Model No.: | 78DP |

|---|---|

| Max pane size: | 14"*20" |

| Independence tolerance: | +/-10% |

| Aspecr Ratio: | 9:1 |

| Layer count: | 1-20 |

| Solder mask abrasion: | ≥8H |

| Gold finger: | Ni: 80~250u", Au: 1~5u" |

| Warp and twist: | ≤0.75% |

| Via plug: | Max via size: 24mil (0.6mm) |

| Peel Strength: | 1.4N/mm |

| Certification: | UL/SGS/ROHS |

| Production Capacity: | 1000square meter/per day |

| Packing: | Inner vacuum and plastic package,outer carton box package |

| Delivery Date: | 3~10days |

Product Description

Quick Details

| Place of Origin: | Guangdong China (Mainland) | Brand Name: | XingDa | Model Number: | XD13010902 |

| Base Material: | FR-4,FR2.Taconic,Rogers,CEM-1 CEM-3,ceramic,crockery,Metal,Alumini | Copper Thickness: | 1/2 oz min; 12 oz max | Board Thickness: | 0.2mm-6mm(8mil-126mil) |

| Min. Hole Size: | 0.1mm(4mil) | Min. Line Width: | 0.075mm(3mil) | Min. Line Spacing: | 0.1mm(4mil) |

| Surface Finishing: | HASL/ HASL lead free, Chemical tin, Chemical Gold, Immersion Gold | Warp & Twist: | 0.7% | Hole Positon: | +/-0.075mm(3mil) CNC Driling |

| Insulation Resistance: | 10Kohm-20Mohm | Conductivity: | <50ohm | Test Voltage: | 10-300V |

| ance Control: | +/-10% | Different Impendance: | +-/10% | Outline Tolerance: | +/-0.125mm(5mil)CNC Routing +/-0.15mm(6mil) by Punching |

| Hole Diameter(H) PTHL: | +/-0.075mm(3mil) Non-PTHL:+/-0.05mm(2mil) | Conductor Width(W): | +/-20% of originalartwork PTH L:+/-0.075mm(3mil) |

Packaging & Delivery

| Packaging Detail: | single side pcb design for led light for traffic sign 1. at buyer's request;2. inner, vaccum package; 3. outer, standard export carton |

| Delivery Detail: | PCB:8-10 workdays; PCBA:20-25 workdays |

Specifications

1.PCB Layout,PCB design

2.1-38 layers boards

3.offer all Electric components

4.ISO9001/TS16949/ROHS

5.deliverytime:10 days

2.1-38 layers boards

3.offer all Electric components

4.ISO9001/TS16949/ROHS

5.deliverytime:10 days

single side pcb design for led lightfor traffic sign

1.PCB Layout,PCB design

2.Make high difficulty PCB(1-38 layersboards)

3.offer all Electric components

4.ISO9001/TS16949/ROHS

5.PCB delivery time:5-10 days; PCBA deliverytime:20-25 days

Welcome to XingDa Electric TechnologyCo.,Ltd

Xindaxing Electric TechnologyCo.,LTd

We are professionalmanufacturer in variousPCB and PCBA with many years experience,We can provide a reasonable price withhigh quality products.

XingDa who canprovide a full set of service.such asbelow:

*1. PCB layout, PCB design

* 2: Make high difficultyPCB(1 to 38 layers)

* 3: Provide all Electroniccomponent

*4: PCB assembly

*5: Write programs for clients

* 6:PCBA/finished product Test. etc.

1.PCB Specificationdetail.

| Item | Specification | |

| 1 | Numbrof Layer | 1-38Layers |

| 2 | Material | FR-4,FR2.Taconic,Rogers, CEM-1 CEM-3,ceramic , crockery Metal-backedLaminate |

| 3 | FinishBoard Thickness | 0.2mm-6.00mm(8mil-126mil) |

| 4 | MinimunCore Thickness | 0.075mm(3mil) |

| 5 | CopperThickness | 1/2oz min;12 oz max |

| 6 | Min.TraceWidth & Line Spacing | 0.075mm/0.1mm(3mil/4mil) |

| 7 | Min.HoleDiameter for CNC Driling | 0.1mm(4mil) |

| 8 | Min.HoleDiameter for punching | 0.9mm(35mil) |

| 9 | Biggestpanel size | 610mm*508mm |

| 10 | HolePositon | +/-0.075mm(3mil)CNC Driling |

| 11 | ConductorWidth(W) | 0.05mm(2mil)or;+/-20%of original artwork |

| 12 | HoleDiameter(H) | PTHL:+/-0.075mm(3mil);Non-PTH L:+/-0.05mm(2mil) |

| 13 | OutlineTolerance | 0.125mm(5mil)CNC Routing;+/-0.15mm(6mil) by Punching |

| 14 | Warp& Twist | 0.70% |

| 15 | InsulationResistance | 10Kohm-20Mohm |

| 16 | Conductivity | <50ohm |

| 17 | TestVoltage | 10-300V |

| 18 | PanelSize | 110×100mm(min);660×600mm(max) |

| 19 | Layer-layermisregistration | 4layers:0.15mm(6mil)max;6 layers:0.25mm(10mil)max |

| 20 | Min.spacingbetween hole edge to circuity pqttern of an inner layer | 0.25mm(10mil) |

| 21 | Min.spacingbetween board oulineto circuitry pattern of an inner layer | 0.25mm(10mil) |

| 22 | Boardthickness tolerance | 4layers:+/-0.13mm(5mil);6 layers:+/-0.15mm(6mil) |

| 23 | ImpedanceControl | +/-10% |

| 24 | DifferentImpendance | +-/10% |

2.Details forPCB Assembly

Technical

1).Professional surface mounting and throughhole soldering technology;

2).Various sizes,like 1206,0805,0603 componentsSMT technology;

3).ICT(In Circuit Test),FCT(Functional CircuitTest) technology;

4).Nitrogen gas reflow soldering technologyfor SMT;

5).High standard SMT&Solder Assemblyline;

6).High density interconnected board placementtechnology capacity.

Quoterequirement

1).The detailed files(Gerberfiles,specification andBOM);

2).Clear pictures of PCBA or samples forus;

3).PCBA Test method.

Advanced ProductionEquipment

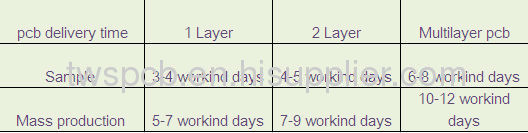

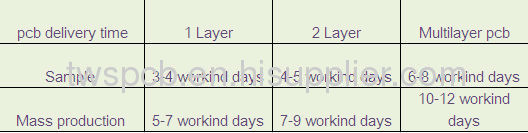

Our deliverytime:

Advanced ProductionEquipment

Product HighQuality Perfect

Our deliverytime:

1.About Factory:

Experience: we have 20 years experinecsin circuit board manufacturing,with 50 employees and 60 excellent engineers,covering an area of 13000 square meters.Monthly capability is more than 5000square meters, 4500 types/month. we cooperate with some well-known enterprises,such as Panasonic, HP,Honeywell and so on.

2.Good after sales service:

anything wrong happening in our products willbe solved within 2 hours. we always offer relative technical support/consultant.Quick response. all your inquiry will be replied within 24 hours.

3.Ourproducts and service are sold well in North America,West Europe, Japan,Singpore, Malaysia and other countries.

Meet your need is ourgreatest pursuit .If you are looking for a pcb board manufacturerinchina,Pleasegive us your files ofpcb for a quote (Gerberfiles and specification),I will reply email in 3hours. Youalso cancontact usby .

1.Advanced production lines andprofessional staff.

2.Honesty credibility in china'stop.

3.Competest price but highquality.

4. One-stopservice.

5.Delivery ontime.