China Multilayer Industrial Control Printed Circuit Manufacturer

57.0~200.0 USD

| Min. Order: | 1 Square Meter |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, D/P, D/A, T/T, WU |

| Supply Ability: | 1000square meter/per day |

| Place of Origin: | Guangdong |

Company Profile

| Location: | Shenzhen, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | PCB |

Product Detail

| Model No.: | 790NM |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Max pane size: | 14"*20" |

| Independence tolerance: | +/-10% |

| Aspecr Ratio: | 9:1 |

| Layer count: | 1-20 |

| Solder mask abrasion: | ≥8H |

| Gold finger: | Ni: 80~250u", Au: 1~5u" |

| Warp and twist: | ≤0.75% |

| Via plug: | Max via size: 24mil (0.6mm) |

| Peel Strength: | 1.4N/mm |

| Certification: | UL/SGS/ROHS |

| Production Capacity: | 1000square meter/per day |

| Packing: | Inner vacuum and plastic package,outer carton box package |

| Delivery Date: | 3~10days |

Product Description

Quick Details

| Place ofOrigin: | Guangdong China (Mainland) | BrandName: | POE | ModelNumber: | PCB-2803 |

| Number of Layers: | 4-Layer | Base Material: | FR4 | Copper Thickness: | 1oz |

| Board Thickness: | 1.6mm | Min. Hole Size: | 0.2mm | Min. Line Width: | 0.1mm |

| Min. Line Spacing: | 0.1mm | Surface Finishing: | HASL | Color: | Green,Blue,Black,Red,Yellow,white |

| Layers: | 1-28 | Finished board thickness: | 0.2-7.0mm | Finised copper thickness: | 1-6OZ |

| PCB Standard: | IPC-A-610 D | Hole tolerance: | PTH: ±3mil, NTPH: ±2mil | Impedence Control Tolerance: | ±5% |

| Certificate: | ISO,UL, SGS and ROHS | OEM/ ODM Service: | One-stop turnkey Service | Small order: | Acceptable |

Packaging & Delivery

| Packaging Detail: | CNC package for bare PCB and ESD package for PCBA aasemble with POE boxPackage |

| Delivery Detail: | 5-10days |

Specifications

1.Multilayer industrial control pcb

2.UL,SGS,RohsCertificate

3.Quick Turn, OEM/ODM

4.China pcb printed circuitmanufacturer

2.UL,SGS,RohsCertificate

3.Quick Turn, OEM/ODM

4.China pcb printed circuitmanufacturer

Detailed ProductDescription

1.High precision industrial controlpcb board

2.4 Layer FR4HASL 1oz copper pcb circuit board

3.Competitiveprice and quick delivery

4.ICT functionand testing instruction test

5.18 yearsOEM,ODM,IC program&test

6.Chinaprofessinoal multilayer printed circuit manufacturer

Layer:4 Layer

Material:FR4

Thickness:1.6mm

Copperthickness: 1oz

MiniHole: 0.2mm

MiniWidth/space: 0.1mm/0.1mm

Testingpoints:4000

SolderMask: LPI Green

Sickscreen:White

Function:Industrial control

Finish:HASL

WELCOME TOPOE

1. POE PCB ManufactureCapability

Item | Capability | |

1.Base Material | FR-4 / High TG FR-4 / Lead free Materials (ROHSCompliant) / Halogen Free material /CEM-3/CEM-1//PTFE/ROGERS/ARLON/TACONIC | |

2.Layers | 1-28 | |

3.Finised inner/outer copper thickness | 1-6OZ | |

4.Finished board thickness | 0.2-7.0mm | |

Tolerance | Board thickness≤1.0mm: +/-0.1mm 1<Board thickness≤2.0mm: +/-10% Board thickness>2.0mm: +/-8% | |

5.Max panel size | ≤2sidesPCB: 600*1500mm Multilayer PCB: 500*1200mm | |

6.Min conductor line width/spacing | Inner layers: ≥3/3mil Outer layers: ≥3.5/3.5mil | |

7.Min hole size | Mechanical hole: 0.15mm Laser hole: 0.1mm | |

Drilling precision: first drilling | First drilling: 1mil Second drilling: 4mil | |

8.Warpage | Board thickness≤0.79mm: β≤1.0% 0.80≤Board thickness≤2.4mm: β≤0.7% Board thickness≥2.5mm: β≤0.5% | |

9.Controlled Impedance | +/-5% | |

10. Aspect Ratio | 15:1 | |

11.Min welding ring | 4mil | |

12.Min solder mask bridge | ≥0.08mm | |

13.Plugging vias capability | 0.2-0.8mm | |

14. Hole tolerance | PTH: +/-3mil NPTH: +/-2mil | |

15.Outline profile | Rout/ V-cut/ Bridge/ Stamp hole | |

16.Surface treatment | OSP: 0.5-0.5um HASL: 2-40um Lead free HASL: 2-40um ENIG: Au 1-10U'' ENEPIG: PB 2-5U''/ Au 1-8U'' Immersion Tin:0.8-1.2um Immersion silver: 0.1-1.2um Peelable blue mask Carbon ink Gold plating: Au 1-150U'' | |

17. E-testing pass percent | 97% pass for the firsttime,+/-2%(tolerance) | |

FQC-Physical Lab: Reliabilitytests | ||

18.Certificate | ROHSUL:E327776ISO9001:2008IPC SGS | |

Our equipments | ||

1.Drilling workshop | 4 drilling bits of drilling machine: 4 sets 2 drilling bits of drilling machine: 2sets | |

2. photo plotting workshop | Israel "ORBOTECH" Photo Plotters | |

3.AOI | AOI machine | |

4.IPQC | "OXFORD" CMI 700 Copper ThicknessTester | |

5.Impedance test | USA "Tektronix" DSA 8200 ImpedanceTester | |

6.Outline workshop | CNC routing machine: 7 sets angle-cutting machine V-cut machine | |

7.Testing Workshop | Surpass X-600: 2sets WTD FT-2808: 5sets WTD HV300: 1set | |

8.X-ray | X-ray machine | |

Acceptable file format | ||

GERBER file, PROTEL series, PADS series, POWERPCB series, AutoCAD series. | ||

Product HighQuality Perfect

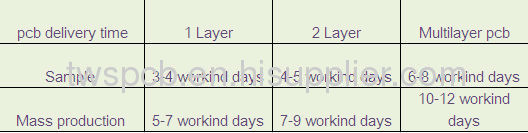

Our deliverytime:

1.About Factory:

Experience: we have 20 years experinecsin circuit board manufacturing,with 50 employees and 60 excellent engineers,covering an area of 13000 square meters.Monthly capability is more than 5000square meters, 4500 types/month. we cooperate with some well-known enterprises,such as Panasonic, HP,Honeywell and so on.

2.Good after sales service:

anything wrong happening in our products willbe solved within 2 hours. we always offer relative technical support/consultant.Quick response. all your inquiry will be replied within 24 hours.

3.Ourproducts and service are sold well in North America,West Europe, Japan,Singpore, Malaysia and other countries.

Meet your need is ourgreatest pursuit .If you are looking for a pcb board manufacturerinchina,Pleasegive us your files ofpcb for a quote (Gerberfiles and specification),I will reply email in 3hours. Youalso cancontact usby .

1.Advanced production lines andprofessional staff.

2.Honesty credibility in china'stop.

3.Competest price but highquality.

4. One-stopservice.

5.Delivery ontime.