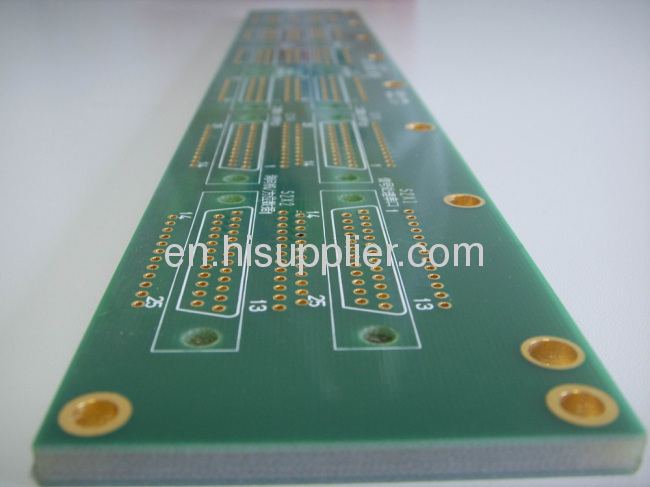

Customized 0.5mm flexiable cable connector

0.1~0.5 USD

| Min. Order: | 10 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Supply Ability: | 300000 Square meter/Month |

| Place of Origin: | Guangdong |

Company Profile

| Location: | Shenzhen, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | PCB |

Product Detail

| Model No.: | tws-HK65 |

|---|---|

| Brand Name: | tws |

| Base Material: | FR4/PI |

| Copper Thickness: | 35um |

| Board Thickness: | 2.3mm |

| Min. Hole Size: | 0.2mm |

| Min. Line Width: | 2mil |

| Min. Line Spacing: | 2mil |

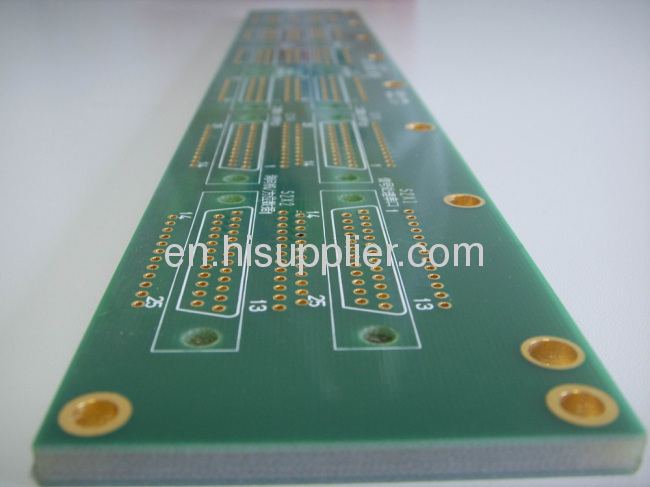

| Surface Finishing: | Gold plating |

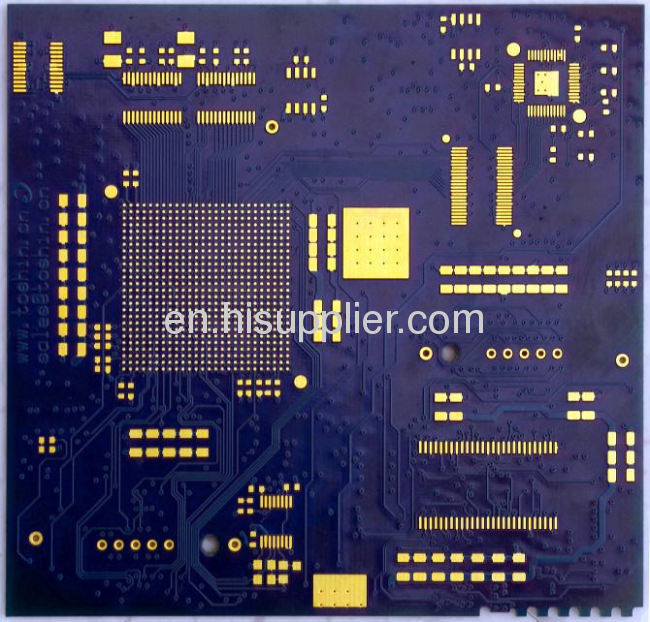

| Solder mask: | Green/Blue/Black/White/Yellow/Red etc |

| Max size of finish board: | 9200*900mm |

| Certification: | UL/SGS/ROHS |

| Controlled impedance: | ±5% |

| Warp&Twist: | 0.7% |

| Rang of finish boards thickness: | 0.21~7.0mm |

| Layer count: | 1~28 |

| Impedance control: | ±10% |

| OEM/ODM: | One-stop service |

| PCB standard: | IPC-A-610D |

| Production Capacity: | 300000 Square meter/Month |

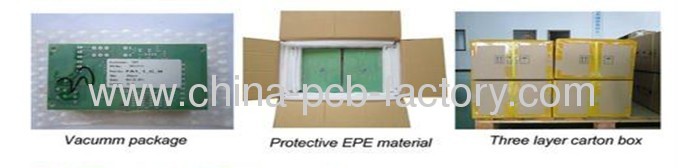

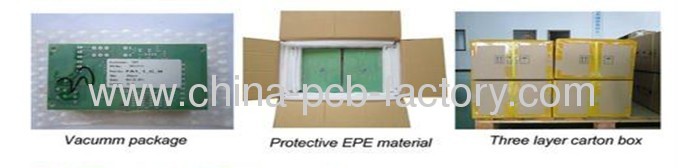

| Packing: | vacuum package+carton box |

| Delivery Date: | 5 days for pcb sample, 15 days for mass pcb order. |

Product Description

0.5mm flexiable cable connector

Materials: PI, copper and Ni/Au

Type: FPC

layers: 1-4 layers

Finished board dimensions: 10 x 15, 250 x 380mm

Board thickness: 0.057 to 0.6mm

Finished board thickness tolerance: ±2 mils

Drill hole diameter: 0.15 to 6.7mm

Finished via diameter: 0.1mm (minimum)

Inner layer dielectric thickness (1/2 mils PI with 15um adhesive): 0.0275 to 0.1mm

Hole diameter tolerance of PTH: ±2 mils

Hole diameter tolerance of NPTH: ±1 mil

Hole position tolerance (compared with Gerber data): ±1 mil

Thickness of PTH hole copper: 8 to 30μm

Tolerance after etching: generally ± 30, 15% for impedance

Tolerance of image to image (minimum): ±3 mils

Tolerance of image to edge (minimum): ±2 mils

Cover layer registration (minimum): 6 mils

Punching hole diameter: 0.1 to 5.0mm

Tolerance of pasting adhesive and stiffener: ±0.3mm

Punching die dimension tolerance (hard die): ±4 mils

Punching die dimension tolerance (soft die): ±12 mils

Impedance tolerance (minimum): ± 10%

SMT tolerance and pitch width (minimum): ±4 mils

Type: FPC

layers: 1-4 layers

Finished board dimensions: 10 x 15, 250 x 380mm

Board thickness: 0.057 to 0.6mm

Finished board thickness tolerance: ±2 mils

Drill hole diameter: 0.15 to 6.7mm

Finished via diameter: 0.1mm (minimum)

Inner layer dielectric thickness (1/2 mils PI with 15um adhesive): 0.0275 to 0.1mm

Hole diameter tolerance of PTH: ±2 mils

Hole diameter tolerance of NPTH: ±1 mil

Hole position tolerance (compared with Gerber data): ±1 mil

Thickness of PTH hole copper: 8 to 30μm

Tolerance after etching: generally ± 30, 15% for impedance

Tolerance of image to image (minimum): ±3 mils

Tolerance of image to edge (minimum): ±2 mils

Cover layer registration (minimum): 6 mils

Punching hole diameter: 0.1 to 5.0mm

Tolerance of pasting adhesive and stiffener: ±0.3mm

Punching die dimension tolerance (hard die): ±4 mils

Punching die dimension tolerance (soft die): ±12 mils

Impedance tolerance (minimum): ± 10%

SMT tolerance and pitch width (minimum): ±4 mils

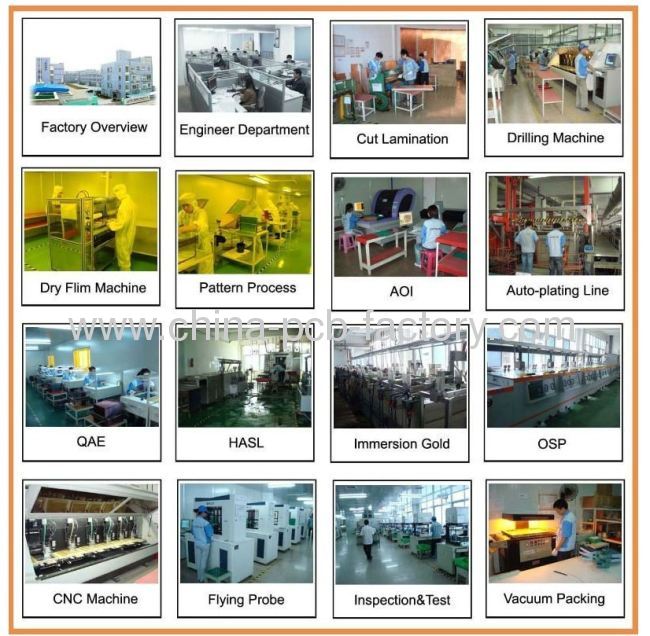

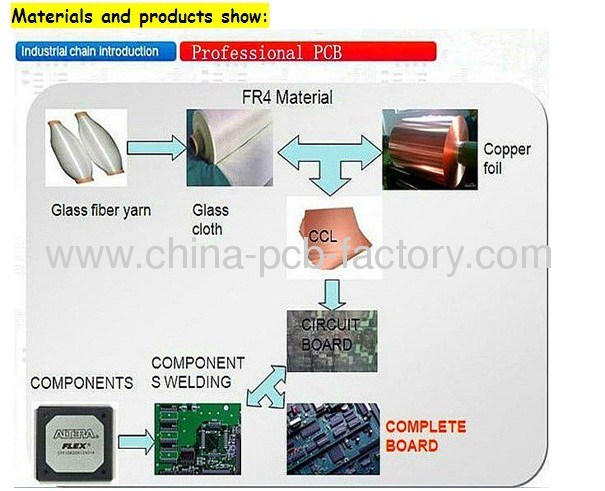

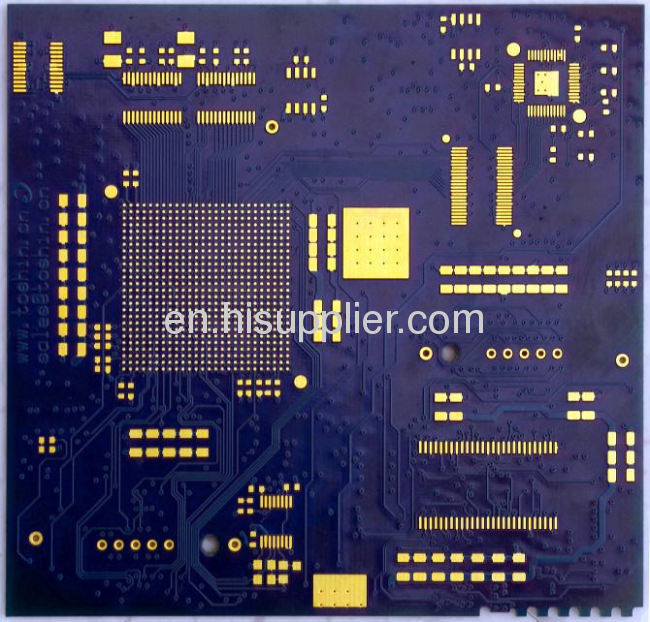

PCB&PCBA information:

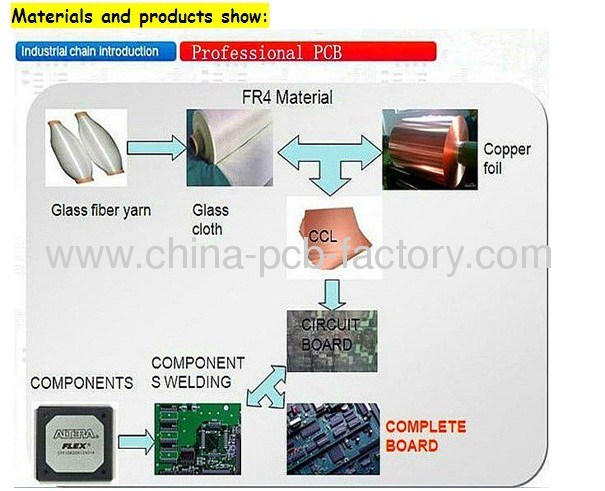

*Base material: FR4, TG, CEM-1, CEM-3, Aluminum

*Copper thickness: 0.5-4.0 oz

*Thickness: 0.2-3.0mm

*Solder mask: green, red, blue, yellow, black, white etc

*Min. line width: 0.2mm

*Min. line space: 0.2mm

*Min. hole diameter: 0.25mm

*Max board size : 600 x 1200mm

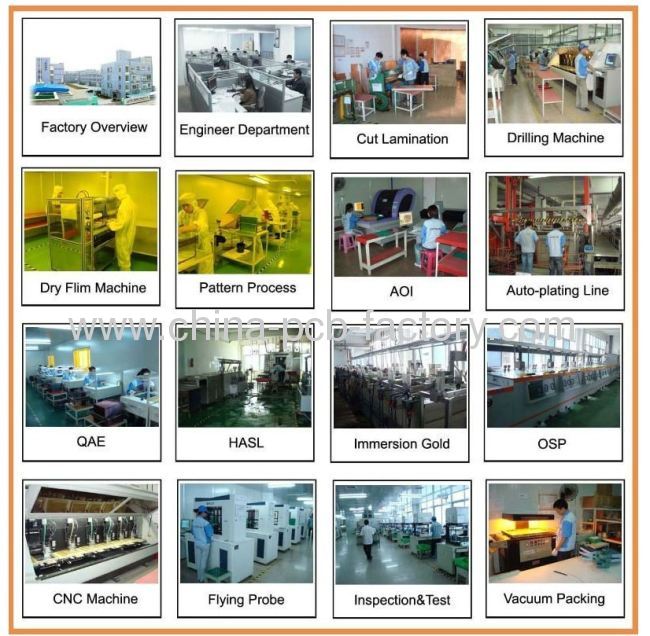

*Surface treatment: spray tin, HASL, lead free, immersion gold, Gold-plate, OSP, ENIG etc

*lead time: seven days

*Capability:30,000 Square Meter/Square Meters / Month

*Copper thickness: 0.5-4.0 oz

*Thickness: 0.2-3.0mm

*Solder mask: green, red, blue, yellow, black, white etc

*Min. line width: 0.2mm

*Min. line space: 0.2mm

*Min. hole diameter: 0.25mm

*Max board size : 600 x 1200mm

*Surface treatment: spray tin, HASL, lead free, immersion gold, Gold-plate, OSP, ENIG etc

*lead time: seven days

*Capability:30,000 Square Meter/Square Meters / Month

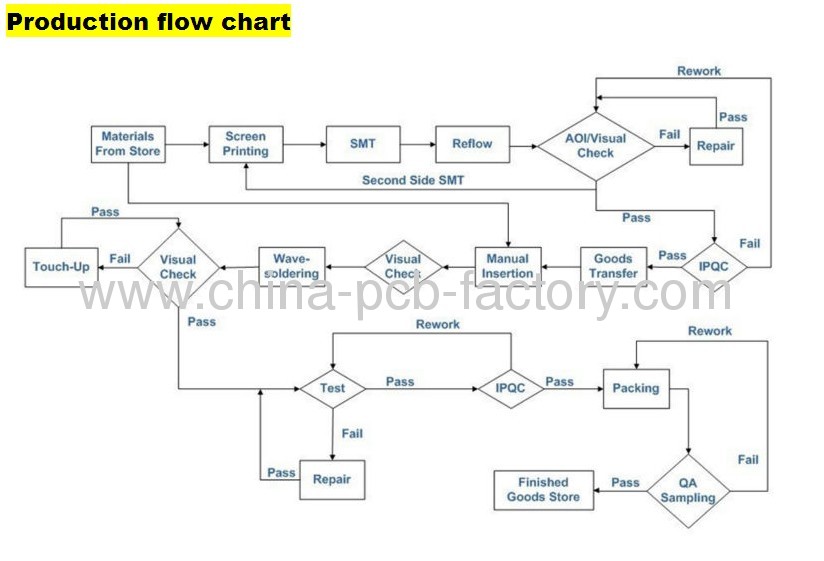

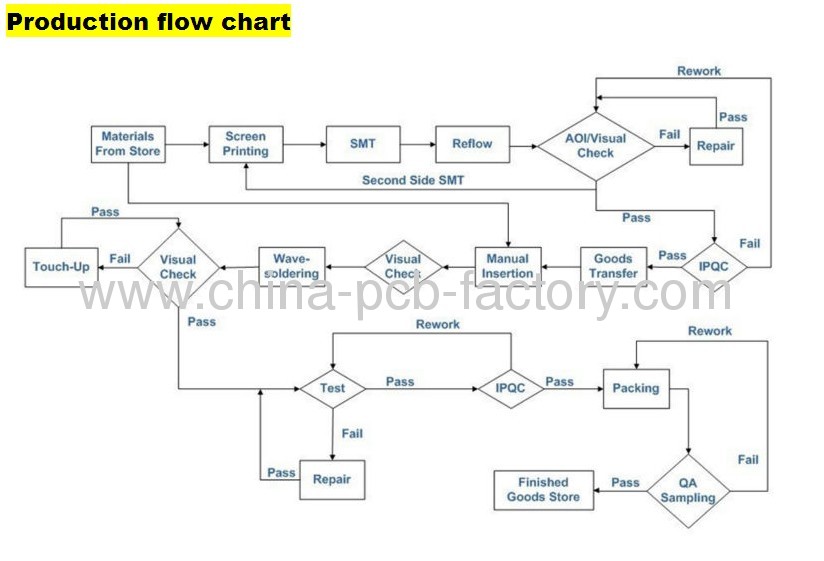

PCBA (printed circuit board with assembly)

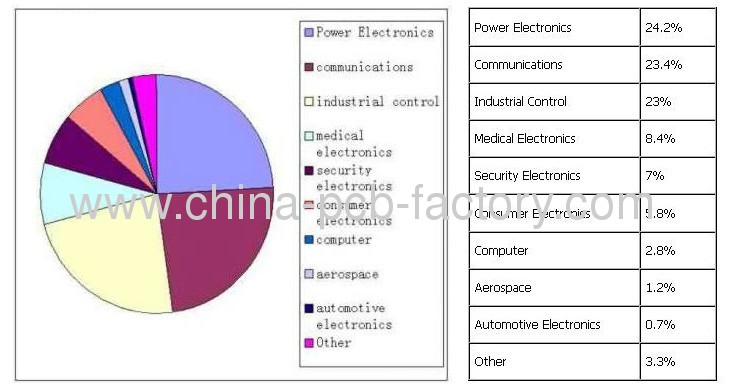

In the continuous pursuit of high flexual resistance, great progress has been made. With the high combination of technology, the very small conjunction conducted by FPC can made better use of space, attaining the higher accurate point, and contributes for the development of electroniccs. It has been widely used in the elelctronic products, such as: mobile phone, camera, computer, LCD etc.

| SPECIFICATION | |

| CAPBILITY-FPC 1 | |

| Material Used | Polyimide, Polyester |

| Maximum Panel Size | 19.7"x24(500x610mm) |

| Line width & Spacing | 3mil(0.075mm) |

| Copper thickness | 1/3oz Min |

| Layer to Layer Registration | ±5mil(0.13mm) |

| Minimum Drill hole Dia | 8mil(0.2mm) |

| Minimum Via Size | 4mil(0.1mm) |

| Lands/Pads | 20mil(0.5mm) |

| Capability-FPC 2 | |

| Hard Gold/Immersion Gold | |

| Surface Finish | HAL for Lead Free |

| Tin Plating | |

| Capability-FPC 3 | |

| Cover layer | Polyimide, Flexible Solder Mask |

| Stiffener material | Polyimide, Polyester, FR4, Metal |

| Shielding material | Copperfoil, Silver foil, Silver Paste |

| Assembly on FPC (Through-hole and SMT) | 0201components, 0.4mm pitch IC& connector |

In the continuous pursuit of high flexual resistance, great progress has been made. With the high combination of technology, the very small conjunction conducted by FPC can made better use of space, attaining the higher accurate point, and contributes for the development of electroniccs. It has been widely used in the elelctronic products, such as: mobile phone, camera, computer, LCD etc.

Advantage:

1.Accurate and strick color matching according to customer's requirement,both Panton and Ral color matching system ,using advanced light box and computer color mataching,we can also do half-tone printing

2. Good material control to make sure all the material are high quality ,all the material we used are Rohns compliant

3.Our engineer will work with customers and reommend specail constrution design to meet customer's desires ,such water proof ,dust proof and anti corrasion and so on

4. Strick quality inspection ,100 % funtional tesiting ,and we can also do specified testing ,such as humility testing ,life expectancy testing ,actuation force testing.

5. We are qualified Dara switch .5. Except membrane switchand touch screen, we can also do different types of assembly,such as membrane switch and touch screen with FPC, PCB ,silicone rubber ,metal backer ,plastic bezel and so on.

6. We can accept small quantity order and offer competitve price.

0.5mm flexiable cable connector