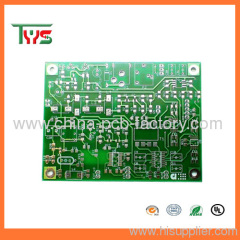

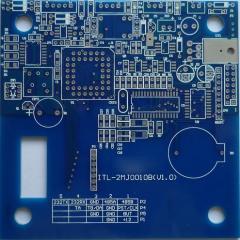

Professional FR4 HASL elevator control board

0.1~0.5 USD

| Min. Order: | 5 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T, WU |

| Supply Ability: | 300000 Square Meter/Square Meters / Month |

| Place of Origin: | Guangdong |

Company Profile

| Location: | Shenzhen, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | PCB |

Product Detail

| Model No.: | tws-017k |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Number of Layers: | 4-Layer |

| Brand Name: | tws |

| Base Material: | fr4 |

| Copper Thickness: | 1oz |

| Board Thickness: | 1.6mm |

| Min. Hole Size: | 0.15mm |

| Min. Line Width: | 0.2mm |

| Min. Line Spacing: | 0.2mm |

| Surface finishing: | HASL&ENIG |

| Solder mask: | Green/Blue/Black/White/Yellow/Red etc |

| Max size of finish board: | 9200*900mm |

| Certification: | UL/SGS/ROHS |

| Controlled impedance: | ±5% |

| Warp&Twist: | 0.7% |

| Rang of finish boards thickness: | 0.21~7.0mm |

| Layer count: | 1~28 |

| OEM/ODM: | One-stop service |

| PCB standard: | IPC-A-610D |

| Production Capacity: | 300000 Square Meter/Square Meters / Month |

| Packing: | vacuum package+carton box |

| Delivery Date: | 10-15 working days for mass pcb order. |

Product Description

HASL elevator control board

PCB Lead time

PCB Assembly Capabilities

Detailed Terms for Pcb Assembly

Welcome to Eastwin-over 15 years professional PCB&PCBA supplier

TWS, your single point of contact for all of your raw materials, parts, and pcb assembly, also offers:

- Contract Manufacturing

- Engineering Services

- PCB Design & Assembly

- Product Design

- Prototyping

- Cable and Wire Assemblies

- Plastics and Molds

- Engineering Services

- PCB Design & Assembly

- Product Design

- Prototyping

- Cable and Wire Assemblies

- Plastics and Molds

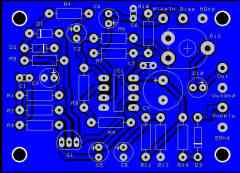

PCB Board Technical capabilities

Layer | 1,2,4 or 6,upto 18 layer |

Material | FR4,CEM1,CEM3,Hight TG,FR4 Halogen Free,FR1,FR2 |

Order Quantity | 1-500,000 |

Board shape | Rectangular,round,slots,cutouts,complex,irregular |

Board type | Rigid,flexible,rigid-flexible |

Board material | FR-4,glass epoxy,FR4 High Tg,Rohs compliant,Aluminum,Rogers,etc |

Board cutting | Shear,V-score,tab-routed |

Board thickness | 0.2~4.0mm,Flex 0.01~0.25'' |

Copper weight | 1.0,1.5,2.0oz |

Solder mask | Double-sided green LPI,Also support red,white,yellow,blue,black |

Silk screen | Double-sided or single-sided in white,yellow,black,or negative |

Silk screen min line width | 0.006'' or 0.15mm |

Max board dimensions | 20inch*20inch or 500mm*500mm |

Min drill hole diameter | 0.01'',0.25mm.or 10 mils |

Surface finish | HASL,Nickle,Imm Gold,Imm Tin,Imm Silver,OSP etc |

Board thickness tolerance | ± 10% |

Copper weight tolerance | ± 0.25oz |

Minimal slot width | 0.12'',3.0mm,or 120mils |

V-score depth | 20-25% of board thickness |

Plated through holes | Yes |

Sink holes | Yes |

Design file format | Gerber RS-274X,274D,Eagle and AutoCAD'S DXF,DWG |

PCB Lead time

Single,Double sided | Four layer | Six layer | Above eight layer | HDI | |

Sample lead time(Normal) | 5-6 | 6-7 | 7-8 | 10-12 | 15-20 |

Sample lead time(Fastest) | 48 to 72 hours | 5 | 6 | 6-7 | 12 |

Mass production lead time(First batch) | 7-9 | 10-12 | 13-15 | 16 | 20 |

PCB Assembly Capabilities

| Quantity | Prototype&Low Volume PCB Assembly,from 1 Board to 250,is specialty,or up to 1000 |

| Type of Assembly | SMT,Thru-hole |

| Solder Type | Water Soluble Solder Paste,Leaded and Lead-Free |

| Components | Passive Down to 0201 size BGA and VFBGA Leadless Chip Carriers/CSP Double-sided SMT Assembly Fine Pitch to 0.8mils BGA Repair and Reball Part Removal and Replacement |

| Bare Board Size | Smallest:0.25*0.25 inches Largest:20*20 inches |

| File Formate | Bill of Materials Gerber files Pick-N-Place file |

| Types of Service | Turn-key,partial turn-key or consignment |

| Component packaging | Cut Tape,Tube,Reels,Loose Parts |

| Turn Time | Same day service to 15 days service |

| Testing | Flying Probe Test,X-ray Inspection AOI Test |

| PCB assembly process | Drilling-----Exposure-----Plating-----Etaching & Stripping-----Punching-----Electrical Testing-----SMT-----Wave Soldering-----Assembling-----ICT-----Function Testing-----Temperature & Humidity Testing |

Detailed Terms for Pcb Assembly

Technical requirement for pcb&pcb assembly:

---- Professional Surface-mounting and Through-hole soldering Technology

---- Various sizes like 1206,0805,0603 components SMT technology

----ICT(In Circuit Test),FCT(Functional Circuit Test) technology.

----PCB Assembly With UL,CE,FCC,Rohs Approval

----Nitrogen gas reflow soldering technology for SMT.

----High Standard SMT&Solder Assembly Line

---- High density interconnected board placement technology capacity.

---- Professional Surface-mounting and Through-hole soldering Technology

---- Various sizes like 1206,0805,0603 components SMT technology

----ICT(In Circuit Test),FCT(Functional Circuit Test) technology.

----PCB Assembly With UL,CE,FCC,Rohs Approval

----Nitrogen gas reflow soldering technology for SMT.

----High Standard SMT&Solder Assembly Line

---- High density interconnected board placement technology capacity.

Quote requirement for pcb&pcb assembly:

----Gerber file and Bom list

----Clear pics of pcba or pcba sample for us

----Test method for PCBA

----Gerber file and Bom list

----Clear pics of pcba or pcba sample for us

----Test method for PCBA

Why us?

---Quality

Our UL/Rohs standards insure quality assemblies from beginning to end. Whether it's a simple custom product or a complex turnkey production run, Eastwin will adhere to the highest quality standards.

-------------------------------------------------------------------------------------------

---Capable

Eastwin offers the latest in assembly capabilities and qualifications insuring that quality is built into every product we produce.

------------------------------------------------------------------------------------------

---Experience

Established in 2001,Eastwin is a professional PCB&PCBA manufacturer with over 10 years experience.Thanks to independent research&development department and sophisticated quality control system,your program will be completed with high quality.

------------------------------------------------------------------------------------------

---Protecting your interests

Protecting your Intellectual Property is our first duty! Our staff,trained professionally,are all working under a strict confidentiality contract.And we treat your important documentation as our own.

Protecting your Intellectual Property is our first duty! Our staff,trained professionally,are all working under a strict confidentiality contract.And we treat your important documentation as our own.

-----------------------------------------------------------------------------------------

---Flexibility

We pride ourselves on our ability to custom programs for our customers' needs. We listen to your unique business needs and set out to achieve your project.

We pride ourselves on our ability to custom programs for our customers' needs. We listen to your unique business needs and set out to achieve your project.

-----------------------------------------------------------------------------------------

NO | ITEM | Technical Data |

1 | Layer | 2-20 Layers |

2 | Board material | FR4,FR4 Halogen free,TEFLON Rogers,Getek High-TG(TG>170),Aluminium base |

3 | Max.Board Size0 | 457*660mm |

4 | Min.Board Thickness | 2 layers 0.2mm |

4 layers 0.4mm | ||

6 layers 0.8mm | ||

8 layers 1.0mm | ||

10 layers 1.2mm | ||

5 | Max.Board Thickness | 8.0mm |

6 | Min.Line Width | 0.05mm |

7 | Min.Line Space | 0.05mm |

8 | Min.Hole Size0 | Electroplating Via 0.15mm |

Micro via 0.075mm | ||

9 | PTH Wall Thickness) | 20-25um |

10 | Max.finish copper thickness0 | 8OZ |

11 | PTH Dia.Tolerance | ±0.05mm |

12 | NPTH Dia.Tolerance | ±0.025mm |

13 | Hole Position Deviation | ±0.05mm |

14 | Outline Tolerance | ±0.1mm |

15 | Min.S/M Pitch | 0.08mm |

16 | Insulation Resistance | 3x10Sec, 288°C |

17 | Warp and Twist | ≤0.7% |

18 | Electric Strength | >1.3KV/mm |

19 | Peel Strength | ≥1.4N/mm |

20 | Solder Mask Abrasion | ≥6H |

21 | Flammability | 94V0 |

22 | Impedance Control | ±5% |

HASL elevator control board