QD general double girder bridge crane

20000.0~100000.0 USD

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, D/P, T/T |

| Supply Ability: | 100 |

| Place of Origin: | Hubei |

Company Profile

| Location: | Xianning, Hubei, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Wire-rope Electric Hoist, Gantry/Bridge Crane |

Product Detail

| Model No.: | QD,QE,QZ,QC,QN,QA |

|---|---|

| Means of Transport: | Ocean, Land |

| Production Capacity: | 100 |

| Packing: | nude packing |

| Delivery Date: | 45 days for OEM, 15 days for ready goods |

Product Description

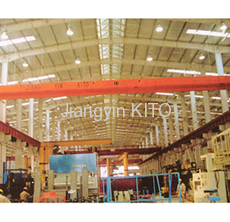

Model QD General Double Girder Bridge Crane

Descriptions:

Model QD Universal Bridge Crane system is designed and built in compliance with GBT14405, it consists of five components that are box span structure, end trucks, trolley, hoisting mechanism and electrical parts. The span structure runs parallelly along suspension I-steel rail that installed in workshops, warehouse or outdoor goods yard, therewith the trolley, can move crosswise along I-steel trolley rail laid on main girder of span structure. This series complete crane system options single or double trolley configurations, and whose hanger is available in hook block, grab bucket, magnetic chuck. Also, as customer's requirements, it can be designed and built to be frequency variable or explosion proof, and can be operated from ground via a control pendant or in cab via control panel.

The QD series bridge crane system is used widely in workshops, mining field, warehouse, goods yard and cargo berth etc for general loading and transporting service in a defined work space indoor or outdoor. It features high stiffness and strength, the moderate duty specifications are suitable for machining and assembly workshops, the heavy duty specifications are suitable for metallurgy workshop and continuous production line.

Work conditions:

Lifting Capacity: | |

Span: | 10.5m, 13.5m, 16.5m,19.5m, 22.5m, 25.5m, 28.5m, 31.5m |

Lifting Height: | Max. 16m |

Work classification : | A5, A6, A7 |

Power supply: | 3-phase AC , 380V, 50Hz |

Ambient temperature : | -20~40 C |

IP Code: | IP55 or IP54 |

Features:

1. Equipped with full vision operation cab and/or ground control pendant.

2. Upper/Lower limit switches, rail sweeper, rubber bumper are standard configurations.

3. Auxiliary brake available

4. Cable festoon and Safety sliding line available for power supply

5. options in single or double lifting hook configurations

6. More alternations and optional solutions to satisfy customer needs