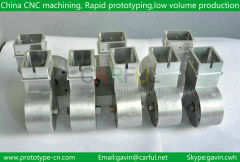

Precision cnc machining anodized aluminium parts

| Min. Order: | 100 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 1000000pcs/month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Machining, Casting, Plastic Parts, Stamping Parts |

Product Detail

| Model No.: | MP13002 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | sureduce |

| Process: | cnc machining |

| Machining type: | drilling, tapping, milling |

| Surface finish: | anodizing,coating,polishing etc |

| Tolerance: | +/-0.05mm |

| Certification: | ISO9001, TS16949 |

| Quality control: | 100% inspected |

| Material: | aluminium 6061 6063 6082 etc |

| Application: | auto parts, machinery part etc |

| Color: | Per customer;s requirement |

| Product name: | Precision cnc machining aluminum parts |

| Production Capacity: | 1000000pcs/month |

| Packing: | standard export package |

| Delivery Date: | 15 days |

Product Description

Description:

1. Name: Precision machining anodized aluminium parts

2. Process: cnc machining

3. Material: aluminium 6061 6063 6082t6 variety

4. Tolerance: +/-0.05mm

5. Machining type: drilling, tapping,milling

6. Surface Finish: polishing ,coating,anodizing etc

7. Dimension: According to customer's drawing or sample

8. Certification: ISO9001:2000/TS16949

9. Application:luxury yacht , machinery part,truck part,Auto part,Industry.

10.Quality control: 100% inspected to ensureevery shipment

11.Color: per customer's requirement for aluminum parts

Production Feature:

| Product Class: | Precision cnc machining aluminium parts |

| Material: | aluminium 6061 6063 682t6 and variety |

| R&D capacity: | 1)Mould/Tooling analysis, design & manufacturing 4)Surface treatment: Trimming, polishing, cleaning & power coating |

| Production Equipments: | Photo show as below |

| Machining Equipments: | 1) CNC milling andturning, grinding, honing, lapping, broaching and other secondarymachining. 2) integral CNC machineries& four machining centers, such as milling, broaching, drilling, turning,planning, grinding machinery and three-axle machining centers. 3) CNC MillingMachine 4) CNC Lathe Machine 5) 4-axismachine |

| Test Equipments: | 1) Hardness tester 2) Chemical analysis 3) Digital Measuring Projector 4) Dynamic Balancing Tester 5) Universal testing machine & Coordinate-Detectorfor CNC machining All test machining can ensure high precision CNC machining parts |

| Quality Certification: | 1) ISO 9001:2000 2) TS16949 |

| Surface Treatment: | 1) Sand blasting 2) Zinc/chrome plating 3) Powder coating 4) Anodizing, 5) Heat treatment etc for CNCmachining 6) Other customerrequirement |

| Production usage: | 1) Auto parts 2) motorcycle parts 3) pump parts 4) locomotive parts 5) machinery parts 6) metal parts 9) precision machining |

We are professional in CNC precision anodized aluminium parts.

We sincerely welcome all domestic andforeign friends to visit our factory.

We are looking forwardto cooperating with you in aluminum parts.