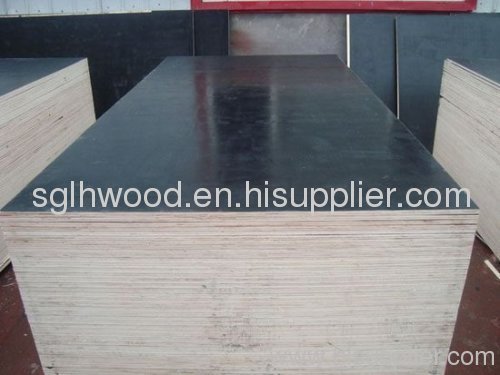

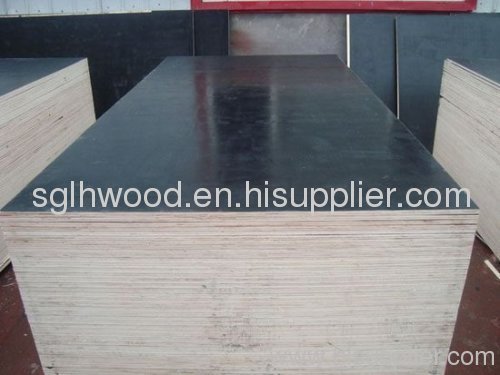

Chinese Film faced plywood & marine plywood

| Min. Order: | 50 Cubic Meter |

|---|---|

| Payment Terms: | L/C, T/T |

| Supply Ability: | 8000CBM per month |

| Place of Origin: | Shandong |

Company Profile

| Location: | Weifang, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Mdf, Particle Board, Plywood, Film Faced Plywood, Melamine Faced Board |

Product Detail

| Means of Transport: | Ocean |

|---|---|

| Brand Name: | sglh |

| film faced plywood/ big sized plywood: | 18mm brown/black film faced plywood with WBP glue |

| 18mm waterproof film faced plywood: | waterproof shuttering film faced plywood for custruction |

| 18mm Black Film Faced Plywood,Marine Plywood: | Film Faced Plywood,Marine plywood for Construction |

| Black Film Faced Plywood,Concrete Formwork Plywood,Anti-Slip Film Faced Plywood,Brown Film Faced Plywood: | construction plywood, water-proof film faced plywood,15mm,18mm concrete template |

| Size: | 1220x2440mm(4'x8'), 1250x2500(4.1'x8.2'), 915x1830(3'x6'), 1500x3000 as per your requirement |

| Length/width tolerance: | +/-2mm |

| Thickness: | 8-24mm |

| Thickness Tolerance: | /-1mm-+/-0.5mm |

| Number of Plies: | From 5 to 15 depending on thickness |

| Face/Back: | Black, Brown, Red, Yellow |

| Production Capacity: | 8000CBM per month |

| Packing: | standard export packages or in bulk |

| Delivery Date: | within 15days after recieved deposit |

Product Description

Chinese Film faced plywood & marine plywood

Merit of our production

| Production Description | |||||||||

| Product Name | China Film Faced Plywood | ||||||||

| Size | 1220x2440mm(4'x8'), 1250x2500(4.1'x8.2'), 915x1830(3'x6'), 1500x3000 as per your requirement | ||||||||

| Length/width tolerance | +/-2mm | ||||||||

| Thickness | 8-24mm | ||||||||

| Thickness Tolerance | +/-1mm-+/-0.5mm | ||||||||

| Number of Plies | From 5 to 15 depending on thickness | ||||||||

| Face/Back | Black, Brown, Red, Yellow | ||||||||

| Core | Poplar, Hardwood, Birch, Combined | ||||||||

| Glue | WBP, Melamine, MR | ||||||||

| PHYSICAL TECHNICAL CHARACTERISTICS | ||||

| No. | Test Item | Unit | Normal Value | |

| 1 | Moisture content | / | 10-14 | |

| 2 | Bonding | Mpa | ≥0.70 | |

| 3 | Bending Strength | Parallel To Grain | Mpa | ≥50 |

| Stripes To Grain | Mpa | ≥30 | ||

| 4 | Modulus Elastiaty | parallel to grain | Mpa | ≥6000 |

| Stripes to grain | Mpa | ≥4500 | ||

| Test conclusion | Conform with the stamdard GB/T 17656-2008 | |||

Merit of our production

1Transference to concrete is set up very easily, so good for construction work. (There is no need for any transference preparation.)

2. It is good to keep surface warm so in winter the project can also be continued.

3 After installation of concrete, the surface looks like a mirror. (The cement does not stick.)

4 The film faced plywood can be used to make camber and it also can be cut into small pieces according the special requirements.

5. Environmentally friendly.

6 It can be used for a long time, and for the initial price paid for the material, you will feel its worth over time