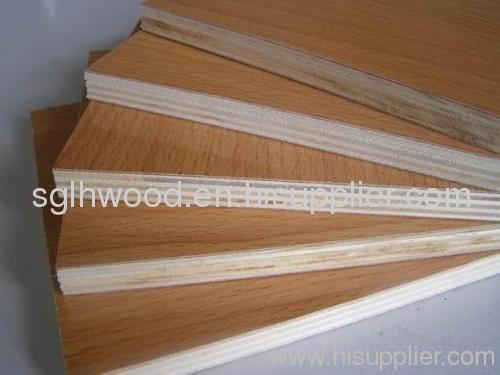

Okoume/Bintangor commercial plywood /furniture grade plywood/Film faced plywood/Marine plywood/Construction plywood

| Min. Order: | 50 Cubic Meter |

|---|---|

| Payment Terms: | L/C, T/T |

| Supply Ability: | 8000CBM per month |

| Place of Origin: | Shandong |

Company Profile

| Location: | Weifang, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Mdf, Particle Board, Plywood, Film Faced Plywood, Melamine Faced Board |

Product Detail

| Means of Transport: | Ocean |

|---|---|

| Brand Name: | sglh |

| 1220x2440mm best quality plywood sheet: | Okoume/Bintangor/Keruing/pencil ceder veneer faced commercial plywood,furniture grade plywood |

| lower price commercial poplar plywood: | Carb Poplar/Hardwood Plywood/Film Faced Plywood |

| plywood from linhai: | Best quality plywood from profession factory |

| Size: | 1220x2440mm,915x2135mm,1250x2500mm |

| Thickness: | 2.5/3.0/3.6/4.0/5.2/6/8/9/0/12/15/18/20/21/25mm |

| Glue: | MR,E1,E2,Melamine,WBP Phenolic |

| Core: | Poplar,birch,combic,hardwood,eucalyptus |

| Face&back: | Okoume,bintangor,birch,pine,agathis,pencil-cedar,bleached poplar,black,brown |

| Grade: | Packing grade&furniture grade |

| Moisture content: | 8%--12% |

| Production Capacity: | 8000CBM per month |

| Packing: | standard export packages or in bulk |

| Delivery Date: | within 15days after recieved deposit |

Product Description

Good qulity plywood

Size | 1220x2440mm,915x2135mm,1250x2500mm |

Thickness | 2.5/3.0/3.6/4.0/5.2/6/8/9/0/12/15/18/20/21/25mm |

Glue | MR,E1,E2,Melamine,WBP Phenolic |

Core | Poplar,birch,combic,hardwood,eucalyptus |

Face&back | |

Thickness | minus or plus 0.2mm--0.5mm |

Moisture content | 8%--12% |

Grade | Packing grade&furniture grade |

Quantity | 8pallets/20ft,16pallets/40ft,18pallets/40HQ |

Payment term | T/T or L/C at sight or D/P or D/A |

Min order quantity | 1x20ft |

Delivery time | 15—20 days upon the receipt of 30% tt deposit or l/c at sight |

Packaging | Inner plastic bags,outer three-ply or paper-box,wrapped with steel tapes by 4x6 lines for reinforce |

Supply ability | 10000ieces per day |

Certificate | FSC,CE,CARB,ISO9001:2000 |

Bintangor commercial plywood /furniture

| vantages: | 1. If put in boiling water for 48 hours, it is still glue-sticking and non-deformed | |||

2. Physical mood is better than iron moulds and can satisfy the requirements of constructing mould, while the iron ones are easy to be deformed and can hardly recover its smoothness even after repairing | ||||

3. If used abide by the illustrations strictly, it can be reused more than 50 times, thus reducing the cost greatly and avoiding the disadvantages from ( rustily and erosive of iron mould) | ||||

4. Solves the problems of leaking and rough surface during constructing process | ||||

5. Particularly suitable for watering concrete project because it can make the concrete surface smooth and flat | ||||