sheet materials corona treater

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | T/T |

| Supply Ability: | need to be ordered |

| Place of Origin: | Guangdong |

Company Profile

| Location: | Shenzhen, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Plasma, Dust Cleaner, Corona Equipment, Electrostatic Eliminator, Reliable Performance Plastic Plate Corona Treater FR-31 |

Product Detail

| Model No.: | FR-31 |

|---|---|

| Means of Transport: | Ocean, Air |

| output power: | 2-8kw, adjustable |

| treating width: | 600/800/1000mm usually |

| treating thickness: | 0.15-1.5MM, Plastic plate materials |

| transmission: | ,frequency control 2-35m/min adjustable |

| treating materials: | insulated plastic plate |

| Optional accessories: | Ozone extractor, electrostatic eliminator |

| Production Capacity: | need to be ordered |

| Packing: | wooden case |

| Delivery Date: | 20days |

Product Description

sheet materials corona treater FR-31

main features:

Generator:output power2-8kw, adjustable

treating thickness:0.15-1.5MM, Plastic plate materials,(the max thickness of special vacuum board is 4-10mm)

treating width:600/800/1000mm usually

Transmission:frequency control,2-35m/min adjustable and slope,platform for materials dropping automatically

Optional accessories:Ozone extractor ,electrostatic eliminator

Specifications

sheet corona treater

1, high efficiency

2,easy tooperate

3. multifunctional

1, high efficiency

2,easy tooperate

3. multifunctional

Feature of Corona treatment:

high switching speed with low losses, combined with the configuration of the power circuits, ensure high performance and complete self-protection in the event of accidental overloads.

Unquestionably, these generators, together with a sophisticated operator terminal and the new discharge stations, represent the most up-to-date state of the art for corona treatment equipment

high switching speed with low losses, combined with the configuration of the power circuits, ensure high performance and complete self-protection in the event of accidental overloads.

Unquestionably, these generators, together with a sophisticated operator terminal and the new discharge stations, represent the most up-to-date state of the art for corona treatment equipment

Corona treating is a very effective way to increase the adhesion of virtually any plastic material. Corona treatment increases the su

rface tension of the Sheet / Fabrics receptive to inks by inducing molecular changes in the surface of the films/sheets.

rface tension of the Sheet / Fabrics receptive to inks by inducing molecular changes in the surface of the films/sheets.

Conventional method of roll to roll treatment is standard practice, but in Offset, Sheet type corona treatment is required to increase surface tension or improve the printability. Some substrates are corona-treated when they are manufactured. Many of these substrates require a surface energy boost to match a particular ink or coating. This is done with corona pretreaters on the press just prior to the coating application point.

PVC, PP, LD, Foam, Flex, metallized polyester, PE, OPP and other high-low density plastic materials should particularly be Corona treated to enhance the quality of the final product.

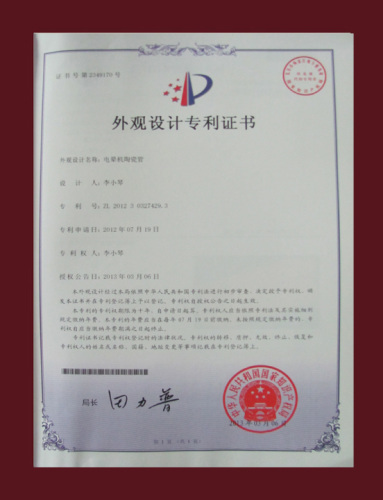

company certification

our exhibition display