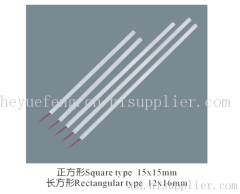

square with groove patent ceramic electrode

810.0 USD

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Payment Terms: | T/T |

| Supply Ability: | have stock |

| Place of Origin: | Guangdong |

Company Profile

| Location: | Shenzhen, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Plasma, Dust Cleaner, Corona Equipment, Electrostatic Eliminator, Reliable Performance Plastic Plate Corona Treater FR-31 |

Product Detail

| Means of Transport: | Ocean, Air |

|---|---|

| Brand Name: | German |

| Max length: | 4000mm |

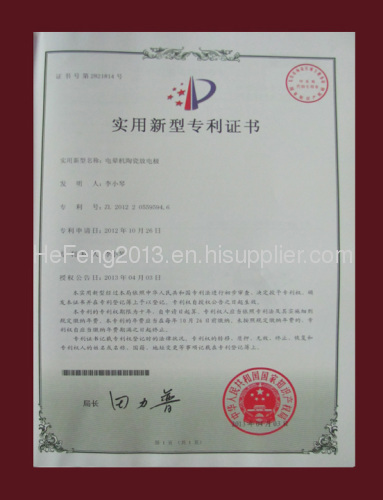

| certification: | our patented ceramic electrode |

| price: | 810dollars/meter |

| type: | square with groove |

| Production Capacity: | have stock |

| Packing: | wooden case |

Product Description

German square with groove patent ceramic electrode

advantage:

1.it can treat both conductiveand insulatied material,such as metal film, laser film, aluminum foil,. aluminum plating film barcode label, metal labels.

2.our corona station is supplied complete with square with groove patent ceramic electrode which is the successfulreduction of damaging, hot streamers produced at the wed inlet and out let, allowing an increase in energy dissipation.

3.High efficiency electrode in stainless steel or ceramic for most printing and lamination applications requiring refreshment of pre-treated substrates or post-treatment of un-treated substrates.

4.our company ceramic electrodes are from German with good and safe quality.it is the best parts choice for corona machine .Uniform discharge, saving electricity.

5.we have a large numbers of stock, the length wii be made in accordance with the customer requirements .

Welcome to consult and purchase.

Corona principle and role

Use high-frequency high-voltage on power pole in the discharge between the rollerand corona, low temperture plasma formed by iionization of air between the ploes to produce ozone,which is a strong oxidizer, can change the molecular structure of plastic surface to make it non-polar into polarity. at the same time after the corona treating, it will cause uneven surface hole roughen,it will enhance surface activity, such as the increase in surface tension, that is , ink,glue,etc,willbe able to further penetrate the materials and processed to achieve the idea effect on the printing and glue application.

our exhibition display

our certification

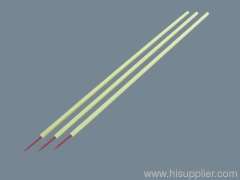

elelctrode is a very important accessories in corona

elelctrode is a very important accessories in corona

Ceramic electrodes make it possible to treat any substrate, even metalized films and foils.

Although rugged, protecting ceramic electrodes from excessive heat and physical shock is of paramount importance. The first step in understanding these enemies of the ceramic electrode is understanding the construction of the electrode itself.Ceramic electrodes must be handled more carefully than metal electrodes. They must be protected from collisions with large substrate splices, tools and any other abrupt contacts. Damage resulting from physical shock is usually manifested in a significant break around the circumference of the ceramic tube. This type of damage is almost always fatal to the electrode and it must be immediately replaced.

For more details, please feel free to contact me, any inquiry from you is appreciated!