PE208 Woven Cloth For Industrial Filter Cloth

1.0~10.0 USD

| Min. Order: | 300 Square Meter |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 1000000M2/M |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | PET Needle Felt For Industrial Filter Cloth, Needle Felt Filter Cloth, Non Woven Cloth/Needle Felt Filter Cloth, PP Industrial Filter Cloth And Filter Bags, Woven Cloth For Industrial Filter Cloth |

Product Detail

| Model No.: | TS-Filter Cloth |

|---|---|

| Means of Transport: | Ocean, Air |

| Style: | Plain |

| Pattern: | Plain Dyed |

| Width: | 47/48" |

| Material: | 100% Polyester |

| Use: | Industrial |

| Brand Name: | Hongxing |

| Production Capacity: | 1000000M2/M |

| Packing: | Under customer's requirements |

| Delivery Date: | 7-25days |

Product Description

Woven filter cloth

Woven filter cloth are mainly used for fabric filtration applications that feature a gentle cleaning system, such as reverse air or shaker systems. Tri-star woven filter cloth are excellent for industrial dedusting and dust collection. They are extensively used in the mining, cement production, and in power generating industries. We provide customized cloth or bags for your specific industrial requirements.

The material ranges for woven filter cloth mainly include:

The material ranges for woven filter cloth mainly include:

1.

TRI-STAR manufacturing the polyester woven filter cloth can be categorized into three types: Polyester spun thread Filter Cloth, Polyester filament Filter Cloth and Polyester monofilament Filter Cloth, which mainly used for filter press, centrifuge filters, etc.

Features: Good Acid-resistance and anti-oxidability, high tensile strength, excellent abrasion resistant.

Applications: Dust collector or liquid-solid separation. Mainly used in food and beverage industry, pharmaceutical industry, non-ferrous metallurgy, chemical plant, building section and mining industry,etc, for the equipment of filter presses, centrifuge filters, vacuum filters, belt filter presses, etc.

Features: Good Acid-resistance and anti-oxidability, high tensile strength, excellent abrasion resistant.

Applications: Dust collector or liquid-solid separation. Mainly used in food and beverage industry, pharmaceutical industry, non-ferrous metallurgy, chemical plant, building section and mining industry,etc, for the equipment of filter presses, centrifuge filters, vacuum filters, belt filter presses, etc.

2. |

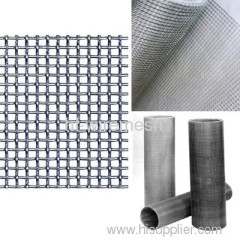

TRI-STARmanufacturing the polypropylene woven filter cloth can be categorized intothree types, PP spun thread filter cloth, PP filament filter cloth and PPmonofilament filter cloth. Features:Acid-resistance, Alkali-resistance, Small specific gravity, high tensilestrength, abrasion proof. Applications:Liquid-solid separation and dust collection. Mainly used in precisionchemical industry, Sugar-refinery, Pharmaceutical, alumina industry, etc, forequipments of frame filter presses, belt filters, blend belt filter, discfilters, drum filters, centrifuge filters, etc |

|