PP Woven Cloth For Industrial Filter Cloth

1.0~10.0 USD

| Min. Order: | 300 Square Meter |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 1000000M2/M |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | PET Needle Felt For Industrial Filter Cloth, Needle Felt Filter Cloth, Non Woven Cloth/Needle Felt Filter Cloth, PP Industrial Filter Cloth And Filter Bags, Woven Cloth For Industrial Filter Cloth |

Product Detail

| Model No.: | PP750A/750B/750AB |

|---|---|

| Means of Transport: | Ocean, Air |

| Style: | Twill |

| Pattern: | Plain Dyed |

| Width: | 47/48" |

| Material: | 100% Polypropylene |

| Use: | Industrial |

| Brand Name: | Hongxing |

| Yarn Count: | PP yarn |

| Density: | 350gsm-550gsm |

| Material: | PP |

| Weight: | PP |

| Air permeability: | 10-30L/M2/S |

| Production Capacity: | 1000000M2/M |

| Packing: | Under customer's requirements |

| Delivery Date: | 7-25days |

Product Description

Polypropylene filtercloth

polypropylenefiber ClothCategory: polypropylene staple fiber filter cloth; polypropylene long-fibercloth

Material properties: acid, alkali, wear resistance, good electrical conductivity and areturn to slightly better than polyester, poor corrosionresistance.

Heatresistance: 90 °C slightly contraction.

Elongation at break (%):18-35.

Elongation at break (%):18-35.

Fracture strength (g / d) :4.5-9.

Softening point (° C) :140-160.

Softening point (° C) :140-160.

Melting point (° C) :165-173.

SpecificGravity: O.9l.

SpecificGravity: O.9l.

Filtering capabilities:

Polypropylenestaple fiber, short fiber, spun into yarn ribbon burr.Polypropylene long-fibercloth , long fiber, the formation of smooth silk yarn. So woven industrialfabrics made ofpolypropylene staple fiber , cloth with burr, powder filter andpressure filter better than long fibers. Andwoven industrial fabrics madeof polypropylene long-fiber cloth ,cloth is smooth,air permeability isbetter.

Usage: chemicals, ceramics,pharmaceuticals, metallurgy, manufacturing, processing filterbottom.

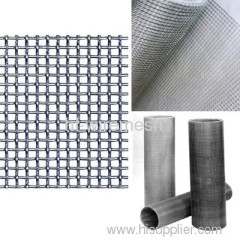

Product Type:

Polypropylene staple fiberfilter cloth:4212

Polypropylene fiber filtercloth :521,527,534,750(AB),750(A),750(B),522,108(B)108(C).

We are eager to establish businessrelations with you and your esteemed company.

Any questions,let us knowfreely.

Name | Material | Texture | Weight g/m2 | Thread/10cm | Thickness mm | Breaking strength |

| Air permeability | ||||

Warp | Weft | Warp | Weft | Warp | Weft | L/M2.S | ||||||

750-1 | Polypropylene filament | twill | 465 | 251 | 149 | 0.95 | 4491.4 | 3933.4 | 50.63 | 34.07 | 49.94 | |

750-2 | Polypropylene filament | twill | 525 | 283 | 141 | 0.05 | 5258.25 | 4221.75 | 46.87 | 35.53 | 37.35 | |

750-3 | Polypropylene filament | twill | 550 | 314 | 133 | 11.1 | 5625 | 4870 | 54.67 | 34.8 | 27.75 | |

750A | Polypropylene filament | Plain | 395 | 204 | 110 | 0.68 | 5060.75 | 2776.75 | 42.87 | 26 | 4.7 | |

522 62×64 | Polypropylene filament | Plain | 155 | 244 | 173 | 0.41 | 900.6 | 1009.4 | 50.67 | 25.77 | 73.44 | |

521 56×38 | Polypropylene filament | twill | 240 | 220 | 150 | 0.63 | 2600 | 2050 | 217 | |||

700-AB | Polypropylene filament | twill | 620 | 377 | 236 | 1.24 | 5168.25 | 5077.5 | 51.83 | 37.37 | 12.92 | |

750-AB | Polypropylene filament | twill | 720 | 377 | 210 | 1.4 | 6718.25 | 5421.75 | 47.50 | 28.3 | 24.41 | |

108B | Polypropylene filament | double bias | 600 | 503 | 133 | 1.1 | 10115 | 3030 | 35.03 | 30.57 | 13.6 | |

108B | Polypropylene filament | double bias | 850 | 503 | 118 | 1.5 | 10603.5 | 4410 | 38.60 | 27.73 | 7.52 | |

108C | Polypropylene filament | satin | 650 | 503 | 220 | 1.15 | 7096.5 | 2818.5 | 55.63 | 35.23 | 6.89 | |

108C | Polypropylene | satin | 600 | 504 | 177 | 1.03 | 6116.5 | 2854.4 | 22.96 | |||