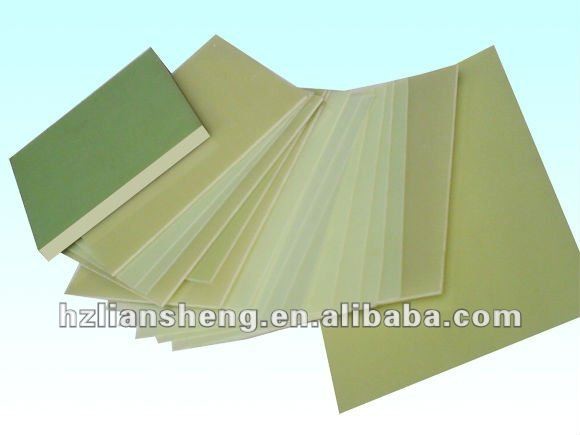

G10 epoxy fiber glass laminate sheet

| Min. Order: | 250 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 500000 per month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Hangzhou, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Copper Clad Laminate, GPO-3, G11, G10, FR4 Material |

Product Detail

| Model No.: | LS |

|---|---|

| Means of Transport: | Ocean |

| Place of Origin: | Zhejiang China (Mainland) |

| Brand Name: | LESON |

| Model Number: | G10 |

| NEMA standard: | EPGC202 |

| Material: | epoxy fiberglass with copper foil |

| Spot goods size(width and length): | 1020X1220mm(40"X48") |

| Thickness: | 0.5mm to 50 mm |

| Flamability: | UL 94 V-0 |

| Color: | Natural(Aqua green),yellow,black |

| Production Capacity: | 500000 per month |

| Packing: | 250 sheets per pallet,wooden pallet |

| Delivery Date: | 10-18 days,according to the quantity of the order |

Product Description

G10 epoxy fiber glass cloth laminate sheet is the sheeted product to be consisted of reinforcing insulation material----glass fiber impregnated with thermoset resin, and then multilayer tablets processed by hot press.

| Normal Type G10 epoxy laminate | |

| 1.Material | Composite polymer(flame- retardant epoxy resin, E-glass fiber cloth) |

| 2.Technics | Mixing ,Coating,Folding,Laminated,Return Line,Cutting,Packing |

| 3.Color | natural color(Light green),yellow,and black |

| 4.Measurement | 1020*1220(40 "×48" ) |

| 5. Feature | Flame retardant, thermal reliability, lower warpage, moisture resistance. |

| 6.Using scope | Instruments and apparatuses, mobile communication, electrotechnics FPC reinforment,testing bed,etc. |

| 7.Packing | carton packaging/ 250 sheet per pallet |

| 8. Certification | ISO9001,ISO14001,CQC,UL |

| 9.Payment | T/T,L/C, Western Union ,USD |

| 10.Technological requirements | For your choices |

Flow Chart

Properities

1.Higher mechanical properties,

2.Dielectric properties.

3.Good heat/Moisture resistance .

4.Stable electric performance in high temperature.

5.Good flatness, smooth surface,no pits

Technician Data

Test Item | Test Condition | Unit | SPEC | Typical Value | |

Tg | DSC | ℃ | ≥120 | 130 | |

Thermal Stress | Unetched | 260℃,10S/solder dip | ____ | No delamination | No delamination No Delamination |

etched | |||||

Surface Resistivity | After moisture | MΩ | ≥1. 0×104 | 2.0×106 | |

Volume Resistivity | After moisture | MΩ.cm | ≥1.0×106 | 2.0×108 | |

Dielectric Constant | 1MHz C-24/23/50 | ____ | ≤5.4 | 4.6 | |

Dissipation Factor(1MHZ) | 1MHz C-24/23/50 | ____ | ≤0.035 | 0.017 | |

Flexural Strength | LW | N/mm2 | ≥415 | 480 | |

CW | ≥345 | 450 | |||

Arc Resistivity | D-48/50+D-0.5/23 | S | ≥60 | 135 | |

Dielectric Breakdown | D-48/50+D-0.5/23 | KV | ≥40 | 60 | |

Moisture Absorption | D-24/23 | % | ≤0.5 | 0.10 | |

CTI | IEC60112 Method | V | ≥175 | 200 | |

Thickness

Standard thickness(mm) | tolerance(mm) | |

Class B/L | Class C/M | |

0.025~0.119 | ±0.018 | ±0.013 |

0.120~0.164 | ±0.025 | ±0.018 |

0.165~0.299 | ±0.038 | ±0.025 |

0.300~0.499 | ±0.050 | ±0.038 |

0.500~0.785 | ±0.064 | ±0.050 |

0.786~1.039 | ±0.100 | ±0.075 |

1.040~1.674 | ±0.130 | ±0.075 |

1.675~2.564 | ±0.180 | ±0.100 |

2.565~3.579 | ±0.230 | ±0.130 |

3.580~6.350 | ±3.00 | ±0.150 |

The services you can enjoy from LESON

Pre-sale consultation After sale service

Ⅰ Quick response on inquires Ⅰ Immediate check of shipping status

Ⅱ Consultation on product properties Ⅱ Guide on how to use produts properly

Ⅲ Advice of material selection Ⅲ Effective solutions to customer complaints

Advantages

1.We are specialized in this industry for more than 20 years, So that ripe experience is gained and manufacturing engineering can be well controlled.

2. We can design and produce the workpiece according to the customers' drawings or samples.

3. We have our own professional and technical engineers to give you before and after sale technical support.

4. We can delivery the goods according to order on time.

5. We will try our best to offer a total solution for you.

Raw material

Product Line

.

1. 5 Coating and laminate production lines

2. CNC machining center :5 sets CNC lathe: 5 sets, milling machines ,routing machines, threading machines, board cutting machine .

3. Technical team with experience of more than 10 years .

4.Costomize different specifications and different quality grades as per customer's requirements .

Stock ,Package,Delivery of FR4 fiberglass laminate

Professional and personalized package ,rapid and promopt delivery.

If you have any question about our products , please feel free to contact us !

.jpg)

.jpg)