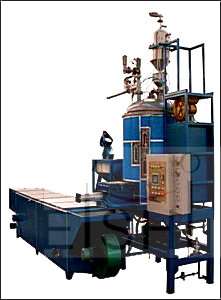

high quality Automatic Batch Pre-expander

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 10 sets one month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Hangzhou, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | EPS Machinery, Plastic Machinery, Foma Machine, Cutting Machine, Block Moulding Machine |

Product Detail

| Model No.: | FDS1100A |

|---|---|

| Means of Transport: | Ocean, Land |

| Plastic Type: | Others |

| Use: | Others |

| Brand Name: | DONGSHAN |

| Volume :: | 1.4m 3 |

| Usable Volume: | 1.0m 3 |

| Entry: | DN50 |

| Consumption: | 6-8kg/cycle |

| Capacity: | 15g/l 500kg/h |

| Connected Load/Power: | 16.5KW |

| Expanded Density: | 12-35kg/m3 |

| Density Tolerance: | <=3% |

| Overall Mimension: | 6300*3400*4300(mm) |

| Weight: | 3500kg |

| Production Capacity: | 10 sets one month |

| Packing: | bare |

| Delivery Date: | 30 days |

Product Description

Products name : high quality Automatic Batch Pre-expander Automatic EPS Batch Pre-expander

Product details :

EPS auto batch pre-expander, eps expansion with one time, making the eps foam beads, eps raw materials

Characteristics:

Technical data :

Product details :

EPS auto batch pre-expander, eps expansion with one time, making the eps foam beads, eps raw materials

it is used for multifunctional pre-expanded machine, it can expand particular low density foamed beads,it can make the low and high density eps material beads together.

it applies the PLC and touch screen monitor automatical control system.

it has the weighing system, feeding material system, temperature control

it keep the density tolerrance within+-2.8%

it has two drying system, it can automatically dry,filter,crush the ball material and transport the foamed material to aging silos.

the closed constant pressure foaming barrel has high heating efficiency, which can save 50% energy compared with the continuous pre-expander.

it applies the PLC and touch screen monitor automatical control system.

it has the weighing system, feeding material system, temperature control

it keep the density tolerrance within+-2.8%

it has two drying system, it can automatically dry,filter,crush the ball material and transport the foamed material to aging silos.

the closed constant pressure foaming barrel has high heating efficiency, which can save 50% energy compared with the continuous pre-expander.

Characteristics:

- This machine applies PLC and touch screen,automatic feeding,electronic weighing,temperature control,material level control to realize automatic production.

- Electronic weighing system and material level control system assure the density of the foamed material, which make the bead uniform and keep the density tolerance within±3%.

- High precise guiding pressure reducing valve controls the temperature and steam pressure of the closed barrel, ensure the outcome pressure of the valve constant and the inner temperature controled within ±1%℃,which keeps the foamed material equal and prevents the bead agglomerate because of the bad temperature control.

- Automatic material charging system improves efficiency and reduces labor intensity.

- The closed constant pressure foaming barrel has high heating efficiency. It can save more than 50% energy compared to the continuous pre-expander.

- The machine is attached with fluidized drying bed,which can automatically dry,crush and filter the foamed materials,then transport to the aging silos.

- Most of the main component are of world-famous brand,with reliable performance,stable quality,long service life and low maintenance cost.

- This machine applies automatic discharging system,the high pressure fan facility improves the speed of discharge.

- The computer has memory function, which can record all information such as brands, specifications, expanding foam techniques and parameters of EPS material manufacturers. When customers want to use the materials that ever been used before just press the touch screen of computer to quickly go back to the original technique.

- This machine is applicable in plateau oxygen depletion area,the production efficiency of continuous pre-expander machine is quite low under such circumstance.

Technical data :

| ITEM | FDS1100A | |

| Expansion Chamber | Diameter | DN110 |

| Volume | 1.4m 3 | |

| Usable Volume | 1.0m 3 | |

| Steam | Entry | DN50 |

| Consumption | 6-8kg/cycle | |

| Pressure | 0.6-0.8Mpa | |

| Compressed Air | Entry | DN25 |

| Consumption | 0.9-1.1m 3 /cycle | |

| Pressure | 0.5-0.8Mpa | |

| Drainage | Upper Drain Port | DN80 |

| Down Drain Port | DN100 | |

| Material Conveying Line | DN50 | |

| Capacity | 12g/l300kg/h | |

| 15g/l500kg/h | ||

| 20g/l600kg/h | ||

| 30g/l750kg/h | ||

| Connected Load/Power | 16.5KW | |

| Expanded Density | 12-35kg/m3 | |

| Density Tolerance | <=3% | |

| Overall Mimension | 6300*3400*4300(mm) | |

| Weight | 3500kg | |