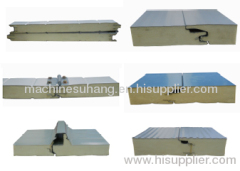

PU(Polyurethane) Continuous Sandwich Panel Production Line

22500.0~120000.0 RMB

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, D/P, D/A, T/T |

| Supply Ability: | 30sets per month |

| Place of Origin: | Jiangsu |

Company Profile

| Location: | Wuxi, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | YX-30-200-993 |

|---|---|

| Means of Transport: | Ocean |

| Power: | Hydraulic |

| Raw Material: | Sheet / Plate Rolling |

| Machine Type: | Roll Forming Machine |

| Extra Services: | Cut To Length |

| Automation: | Manual |

| Certification: | ISO 9001:2000 |

| Material / Metal Processed: | Brass / Copper |

| Brand Name: | Wuxi Suhang Machinery |

| Production Capacity: | 30sets per month |

| Packing: | naked |

| Delivery Date: | 45-90days |

Product Description

Main Features of Discontinuous PU(Polyurethane) Sandwich Panel Production Line:

1.The SP-PU-C/M Colored Steel Sandwich Panel Production Line mainly consists of the two sets of Uncoiler, Steel Panel Transverse Cutting Machine, Steel Panel Surface PVC Film covering device, Roll forming machine (3 sets) and Platform (up and down), Pre-heating room, PU injecting section for foaming, Panel automatically cutting system and Cooling system conveyer, Automatic stacking machine;

2. Foaming and the maturing double belt machine includes hydraulic pressure control system (24 meters length) and 4 sets side nylon seal blocks to make wall panel and roof panel;

3.Using heated air recycle oven, the temperature of PU foaming and solidification strictly controlled.

4.Production capacity of this production line: 3-8m/min.

Panel width: 800-1000mm, panel thickness: 30-150mm.

Total power: about 150kw, working pressure on pouring foam: 150-200bar (high pressure foaming);

5.Valid length of double belt conveyer: 24m.

1.The SP-PU-C/M Colored Steel Sandwich Panel Production Line mainly consists of the two sets of Uncoiler, Steel Panel Transverse Cutting Machine, Steel Panel Surface PVC Film covering device, Roll forming machine (3 sets) and Platform (up and down), Pre-heating room, PU injecting section for foaming, Panel automatically cutting system and Cooling system conveyer, Automatic stacking machine;

2. Foaming and the maturing double belt machine includes hydraulic pressure control system (24 meters length) and 4 sets side nylon seal blocks to make wall panel and roof panel;

3.Using heated air recycle oven, the temperature of PU foaming and solidification strictly controlled.

4.Production capacity of this production line: 3-8m/min.

Panel width: 800-1000mm, panel thickness: 30-150mm.

Total power: about 150kw, working pressure on pouring foam: 150-200bar (high pressure foaming);

5.Valid length of double belt conveyer: 24m.