API Spec 7-1 Drilling Kelly Wholesale ( factory direct)

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Trade Term: | FOB,CFR,CIF,DDP,DAP,CIP,CPT,FCA,EXW |

| Payment Terms: | L/C, D/P, D/A, T/T |

| Supply Ability: | 800 joints per month |

| Place of Origin: | Shaanxi |

Company Profile

| Location: | Xi'an, Shaanxi, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent, Distributor/Wholesaler, Service, Association, Other |

| Main Products: | 8-1/2 Spiral Blade Stabilizer AISI 4145H MOD, AISI 4145H MOD Stabilizer For Well Drilling, 4 1/2 RTTS Safety Joint, 5 RTTS Safety Joint, RTTS PACKER |

Product Detail

| Means of Transport: | Ocean, Air, Land |

|---|---|

| Standard: | API Spec7-1 |

| Steel Grade: | G105, S135 |

| Machine Type: | Drilling Equipment |

| Material: | AISI 4145H |

| Processing Type: | Casting |

| Coating: | as per requirements |

| Marking: | According to standard or according the client's requirement |

| Packing: | In bundles or Loose |

| Shipping: | 15days for stock and 30-60days for new products |

| Application: | Well Drilling |

| Production Capacity: | 800 joints per month |

| Packing: | seaworthy packing |

| Delivery Date: | 30 days after received advance apyment |

Product Description

API Spec 7-1 Drilling Kelly Wholesale

Features

Square Kelly for oilfield drilling equipments

4145H mod Downhole Drilling Tools Drill Collars

Forgings mainly include: Drill tools, stabilizers, Forged mill rollers,Forged shafts,Forged bars, round hollow bars,Forged piston, Forged cylinders,Forged Rring&discs,Pipe Mold,etc.

Parameter

Kelly Size | Length of Drive Section (m) | Length Overall (m) | Drive Section | ||||||||

Standard | Optional | Standard | Optional | Across Flats DFL | Across Corners EC | Acros Corners DCC

| Radius | Radius | Min. Wall ECC. Boret | ||

63.5 | (2 1/2) | 11280 | 12190 | 63.5 | 83.3 | 82.55 | 7.9 | 41.3 | 11.43 | ||

76.2 | (3) | 11280 | 12190 | 76.2 | 100.0 | 98.43 | 9.5 | 49.2 | 11.43 | ||

88.9 | (3 1/2) | 11280 | 12190 | 88.9 | 115.1 | 112.70 | 12.7 | 56.4 | 11.43 | ||

108.0 | (4 1/4) | 11280 | 15540 | 12190 | 16460 | 108.0 | 141.3 | 139.70 | 12.7 | 69.9 | 12.07 |

108.0 | (4 1/4) | 11280 | 15540 | 12190 | 16460 | 108.0 | 141.3 | 139.70 | 12.7 | 69.9 | 12.07 |

133.4 | (5 1/4) | 11280 | 15540 | 12190 | 16460 | 133.4 | 175.4 | 171.45 | 15.9 | 85.7 | 15.88 |

133.4 | (5 1/4) | 11280 | 15540 | 12190 | 16460 | 133.4 | 175.4 | 171.45 | 15.9 | 85.7 | 15.88 |

Kelly Size | Upper Box Connection | Lower Pin Connection | Inside | ||||||||||

size and style LH | Outside Diameter | Bevel Diameter | Size and Style | Outside | Length | Bevel Diameter | |||||||

Standard | Optional | Standard | Optional | LU | DF | DF | |||||||

63.5 | (2 1/2) | (6-5/8)REG | (4-1/2)REG | 196.9 | 146.1 | 406.4 | 186.1 | 134.5 | NC26 | 85.7 | 508 | 82.9 | 31.8 |

76.2 | (3) | (6-5/8)REG | (4-1/2)REG | 196.9 | 146.1 | 406.4 | 186.1 | 134.5 | NC31 | 104.8 | 508 | 100.4 | 44.5 |

88.9 | (3 1/2) | (6-5/8)REG | (4-1/2)REG | 196.9 | 146.1 | 406.4 | 186.1 | 134.5 | NC38 | 120.7 | 508 | 116.3 | 57.2 |

108.0 | (4 1/4) | (6-5/8)REG | (4-1/2)REG | 196.9 | 146.1 | 406.4 | 186.1 | 134.5 | NC46 | 158.8 | 508 | 145.3 | 71.4 |

108.0 | (4 1/4) | (6-5/8)REG | (4-1/2)REG | 196.9 | 146.1 | 406.4 | 186.1 | 134.5 | NC50 | 161.9 | 508 | 154.0 | 71.4 |

133.4 | (5 1/4) | (6-5/8)REG | 196.9 | 406.4 | 186.1 | 5 1/2FH | 177.8 | 508 | 170.7 | 82.6 | |||

133.4 | (5 14) | (6-5/8)REG | 196.9 | 406.4 | 186.1 | NC56 | 177.8 | 508 | 171.1 | 82.6 | |||

Pictures

About us

We specialize in producing and selling API standard drill pipe from 2-3/8''OD to 5-1/2''''OD.with steel grade E75,X95,G105,S135.We can supply both NC,IF,FH connection type and special connection type as HT55.Mainly used in oil and gas exploration and development process of deep well,horizontal well and extended reach well.

Drill pipe is a portion of the overall drill string. The drill string consists of both drill pipe and the drill stem which is the tubular portion closest to the bit or downhole assembly. Drill pipe and drill stems can be differentiated in that the drill pipe is quite flexible and produced in longer segments whereas the drill stem is much more rigid and manufactured in shorter task specific segments.

Drill Pipe Feature:

A. High precision in size and shape

B. Good low temperature toughness

C. Excellent comprehensive mechanical properties

D. High connection strength and sealability

E. Large inside diameter of tool joint

F. Hightorque resistance

G. High fatigue strength and long fatigue life

Internal Coating Feature:

A.High abrasion resistance and low friction factor

B. Good adhesion and flexility

C. High application temperature and pressure

D. High hardness and impact resistance

E. Good corrosion resistance

Hardbanding Feature:

A. Good balance between antiwear and friction-reduction

B. The wear rate is less than 6% of that of bare tool joint, which can prolong 3 times of the

tool joint service life

C. Good property of friction-reduction, which can reduce the casing wear to the least, and its

wear to casing is less than 11% of that of bare tool joint

D. Reduce the torque of drilling string

E. Good weldablity with little splash and good rewelding preformance

F. Friendly to environment

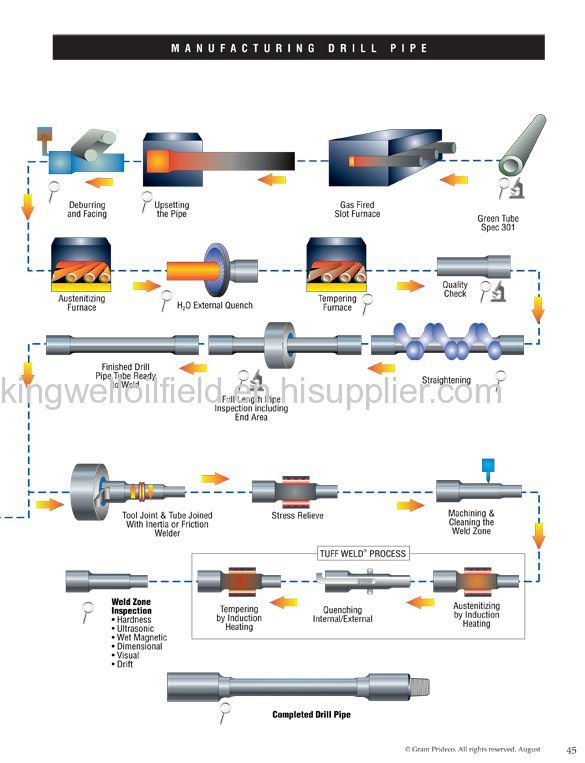

Our Production Line

About delivery:

About Logo: KW, we can produce according to customer requirements.

About Quality: All the products with API, low price are not -API, cannot be exported.

About Warranty: Warranty period is 1 year after installation.

About Payment: 30% of the advance payments, delivery time, please pay 70%.

About Ttechnical Documents: I submit the following accompanying technical information in English,

A: Test Report in accordance with the appropriate API or national test standards outline

B. Commerial Invoice

C: Original copy of quality certificate

D: Packing List

E: The chemical element ,Mechanical properties.

About Service:

We believe in Customer delight, achieved by the supply of Quality Products & Services and Continual Improvement in our Manufacturing Processes for timely delivery at competitive prices. We work in a professional, competitive, and cost-effective manner consistent with the Customer requirement.

Any Inquiry or Advance will be highly appreciated!